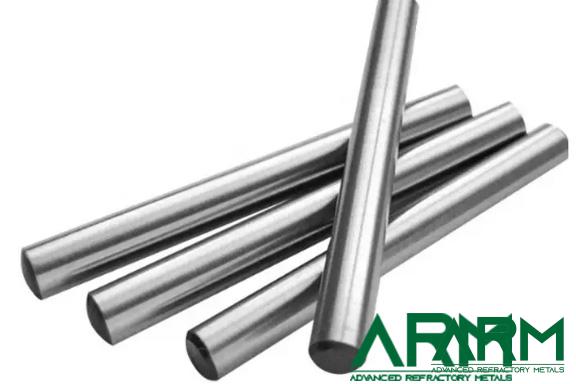

NT0401 Nitinol Wire/Rod (Nickel Titanium)

Shape Memory Alloy (SMA) are one of the most promising smart materials available today, and they can provide the novel solution in several fields and for various applications (e.g.

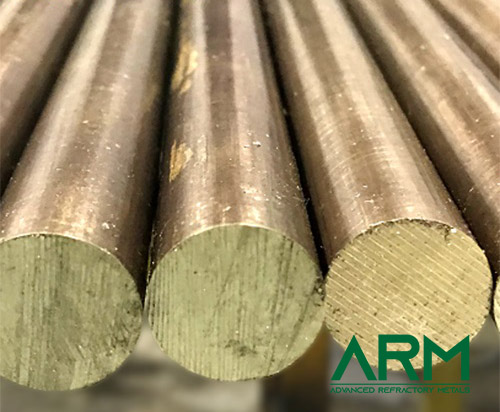

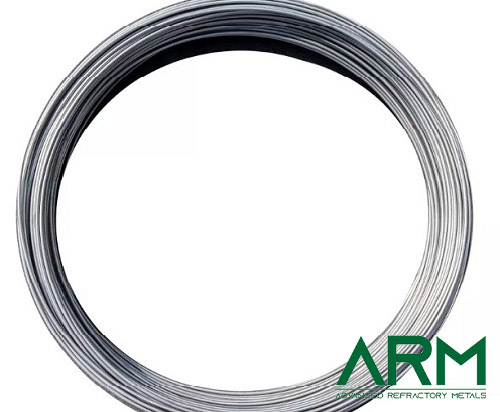

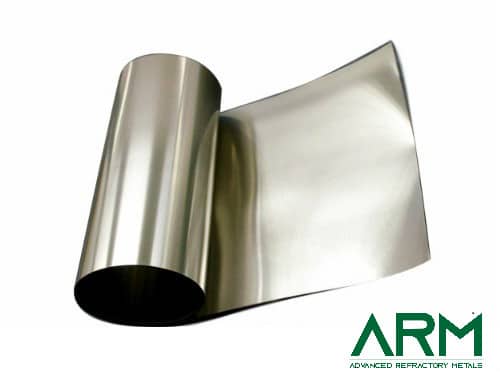

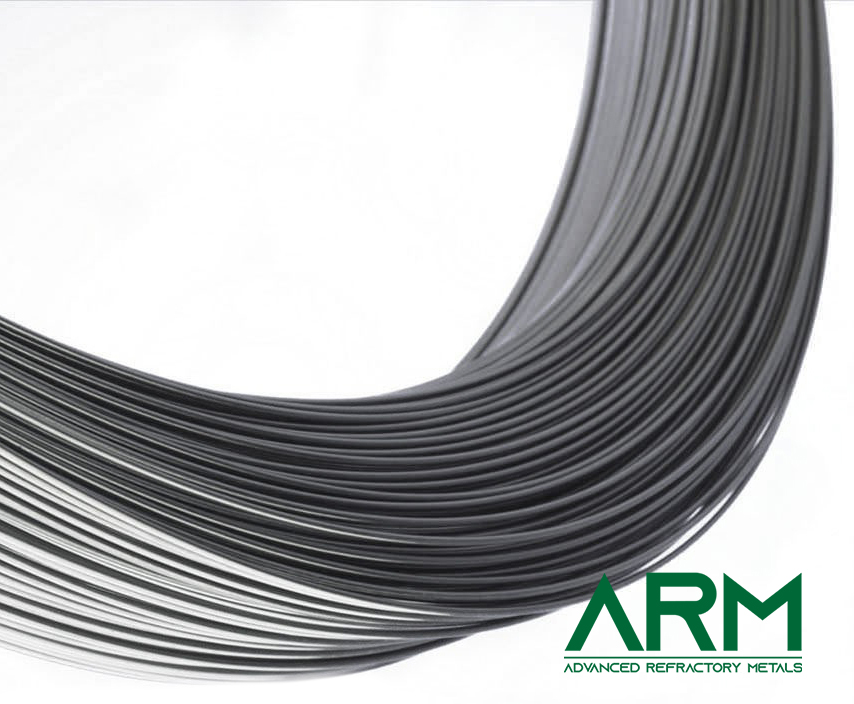

Descriptions of Nitinol Wire/Rod

Shape Memory Alloy (SMA) are one of the most promising smart materials available today, and they can provide the novel solution in several fields and for various applications (e.g. actuator, biomedical application, clamping systems, etc.). Shape Memory Alloys demonstrate a unique ability to recover their initial shape after deformation through a reversible thermo-elastic phase transformation.

Among the commercially available SMA, nickel-titanium (Ni-Ti and Ni–Ti-based) alloys are outstanding due to their excellent performance, reliability, and strain recovery properties. Ni-Ti alloy is attractive for various medical applications due to its biocompatibility, corrosion resistance, and fatigue behavior.

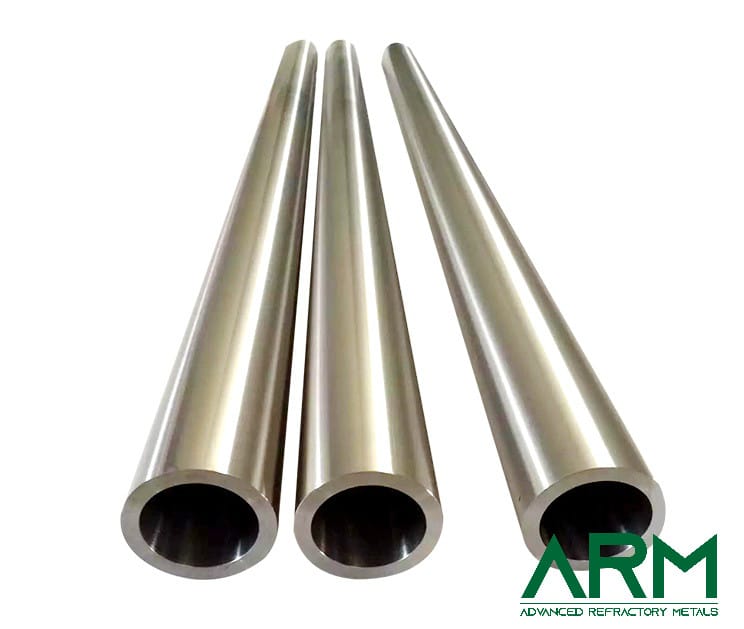

Advanced Refractory Metals (ARM) is a leading supplier of Nitinol Alloy products. All custom sizes and finished parts can be produced quickly to the highest industry standards.

Specifications of Nitinol Spring

|

Product Name |

Nitinol Wire |

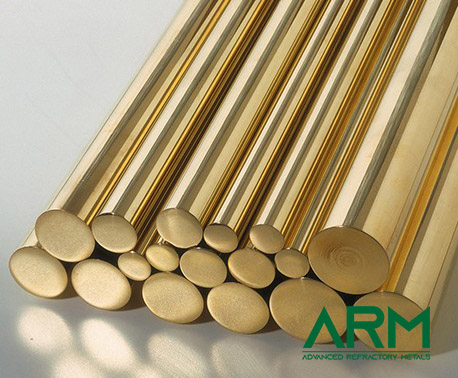

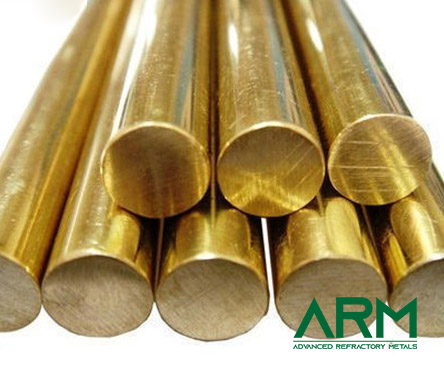

Nitinol Rod |

|

Size |

0.004”-0.2” Diameter |

>0.2” Diameter |

|

Surface Finish |

Black, Pickled, Polished (Dia.>0.04”) |

Black, Pickled, Polished |

|

Forms |

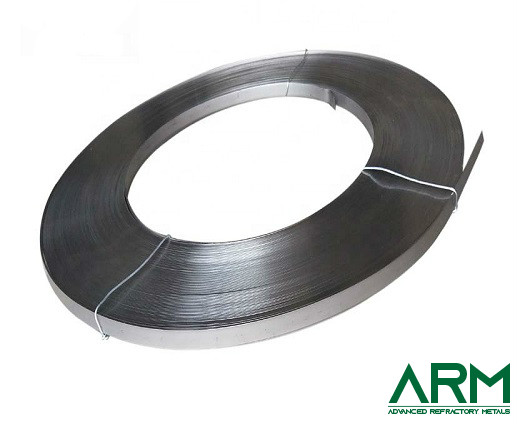

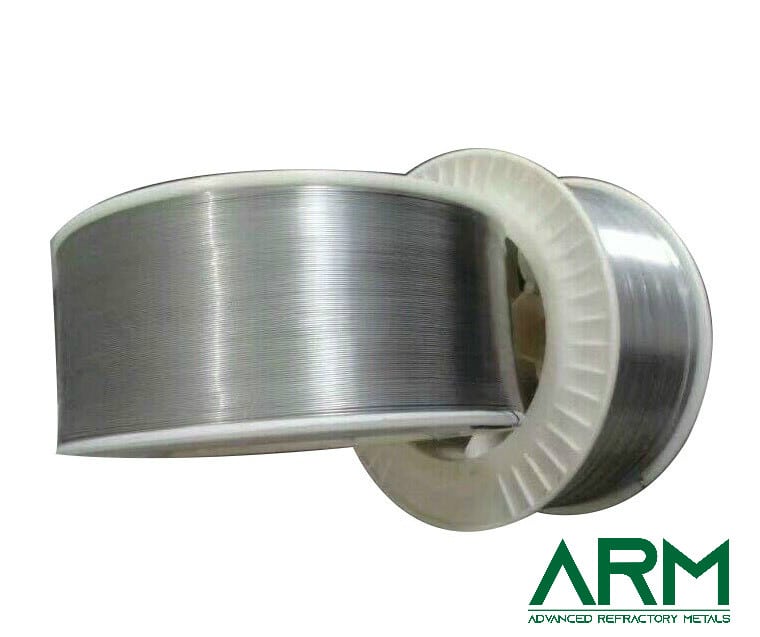

Straight wires, Coils, Spools |

Straight rods |

|

Applications |

Dental braces, Stent, Fishing wire, Springs, Eyeglass frames, etc. |

|

|

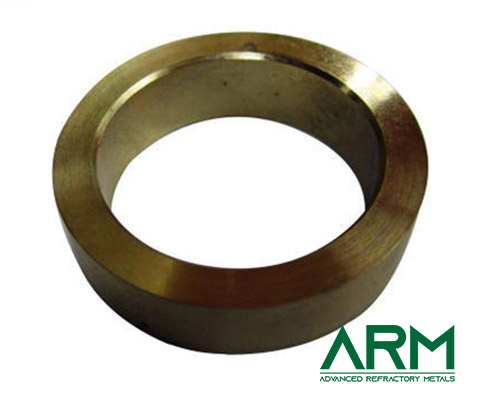

Other available geometries |

Square/Rectangular wire and other customized shapes |

Bar and other customized shapes |

Properties of Nitinol Wire/Rod

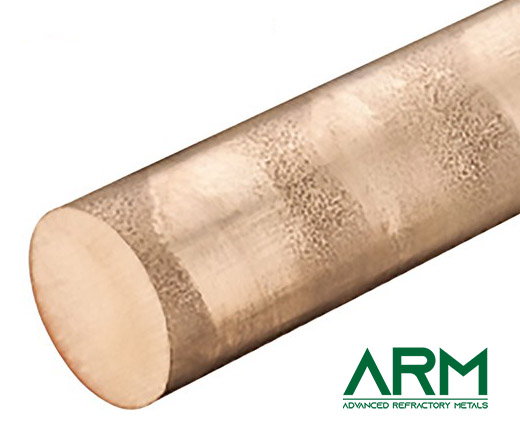

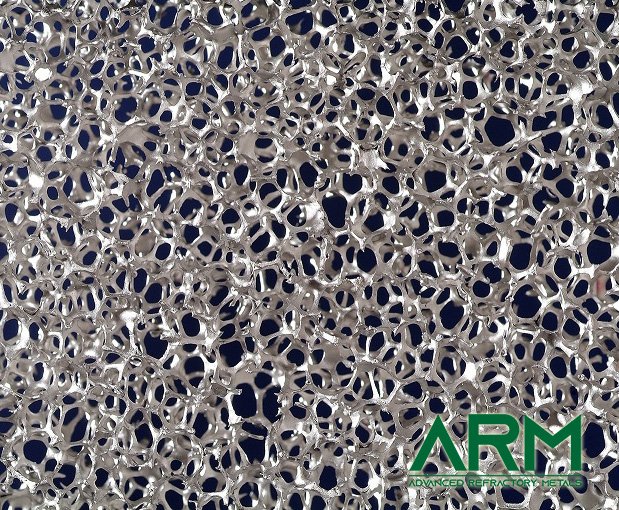

Nitinol is a nickel-titanium alloy with superelasticity and shape memory properties. Shape memory refers to the ability of Nitinol to undergo deformation at one temperature and then recover its original, under-formed shape upon heating above its transformation temperature. Superelasticity occurs at a narrow temperature range just above its transformation temperature; in this case, no heating is necessary to cause the under formed shape to recover, and the material exhibits enormous elasticity, some 10-30 times that of ordinary metal.

Nitinol technical properties

1. Values listed are for a full martensite to austenite transition;

2. Hysteresis can be significantly reduced by partial transformation or ternary alloys;

3. Similar to 300 series stainless steel or titanium;

4. Highly nonlinear with temperature.

Applications of Nitinol Wire/Rod

Nitinol wire is used for many different medical and industrial applications. The table below gives some typical engineering applications for each of our standard Nitinol medical grades:

1. Guidewires, stents, stylets, forming mandrels, stone retrieval baskets, orthodontic files, etc.

2. Often used in applications that require a high loading and unloading plateau stress at room temperature. Chromium-doped for decreased transformation temperature and increased tensile strength.

3. Applications requiring increased stiffness. Cobalt-doped for decreased transformation temperature and increased tensile strength.

4. Provides the best cycling performances at body temperature (37°C).

5. A common application for this alloy is high-temperature actuators.

6. A common application for this alloy is high-temperature actuators.

7. Typically used in applications that require a phase transformation at body temperature (37°C).

8. For use in very cold temperature environment applications.

Packaging of Nitinol Wire/Rod

Our Nitinol Springs are clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-