WM0146 Tungsten Powder (High Purity W Powder)

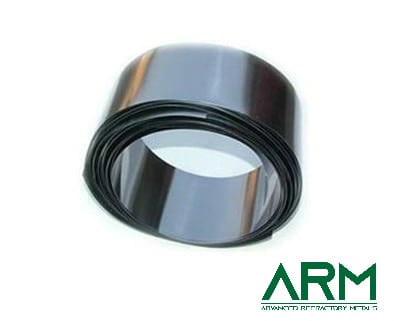

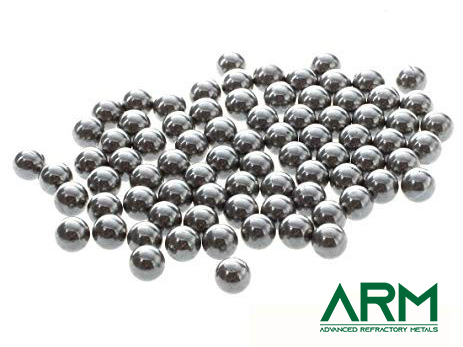

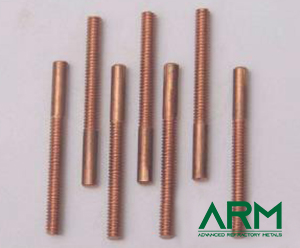

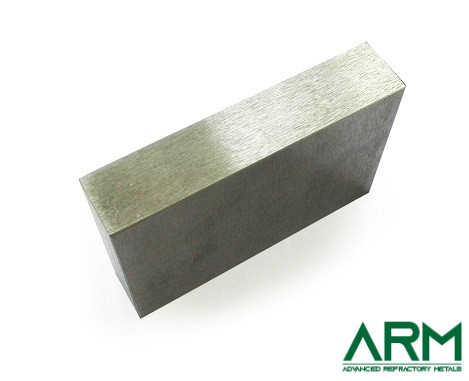

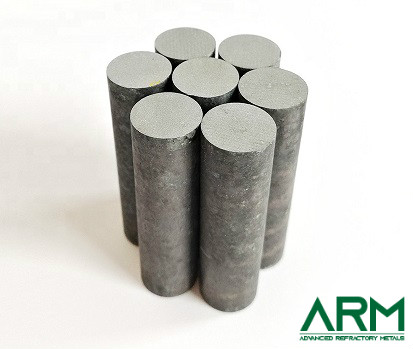

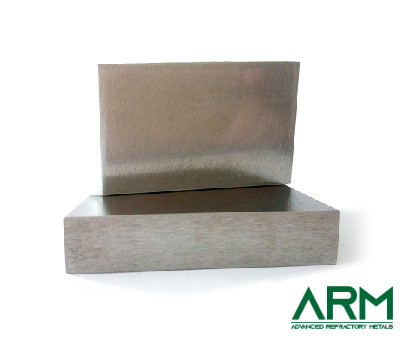

Tungsten Powder is spheroidal in shape and gray in color. Advanced Refractory Metals manufactures tungsten powder for use in electrical contacts, airbag deployment systems, and as the beginning material in tungsten mill products and wire.

Descriptions of Tungsten Powder

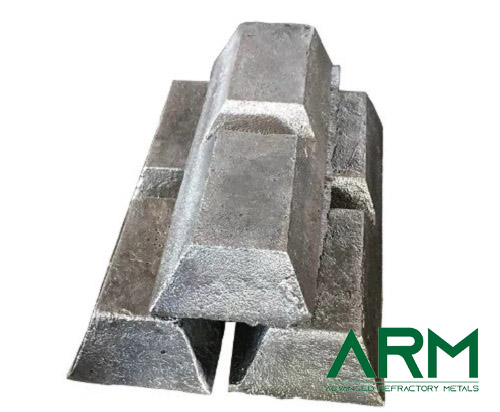

Tungsten powder is a fine, gray metallic powder made from high-purity tungsten. It is known for its extremely high melting point (3422°C), high density, excellent thermal and electrical conductivity, and exceptional hardness. Typically produced through hydrogen reduction of tungsten oxides, this powder is essential for applications requiring heat resistance, strength, and durability. It serves as a key raw material in powder metallurgy for manufacturing tungsten-based components, including filaments, electrodes, electrical contacts, and heavy metal alloys. Tungsten powder is available in various particle sizes and purities to suit specific industrial and technical requirements.

s.

Specifications of Tungsten Powder

| Particle Size | Minimum 85% > 70 Microns |

| Particle Size Distribution | Minimum 90% between 100 and 200 Mesh |

| Bulk Density | Minimum 18.50 g/cc (Helium Pycnometer) |

| Tap Density | Minimum 11.90 g/cc (ASTM B527) |

Applications of Tungsten Powder

-

Powder Metallurgy: Used to produce tungsten-based alloys and components.

-

Electrical Contacts: Suitable for high-temperature and high-voltage environments.

-

Radiation Shielding: Used in medical and nuclear shielding due to high density.

-

Additive Manufacturing: Suitable for 3D printing of heat-resistant components.

-

Military and Defense: Used in armor-piercing ammunition and kinetic energy penetrators.

Types of Tungsten Powder

| Type | Purity | Particle Size | Key Applications |

|---|---|---|---|

| Pure Tungsten Powder | ≥99.95% | 1–20 μm | Metallurgy, electrodes, filaments |

| Spherical Tungsten Powder | ≥99.95% | 10–105 μm | 3D printing, MIM, thermal spraying |

| Nano Tungsten Powder | ≥99.9% | <100 nm | Coatings, electronics, R&D |

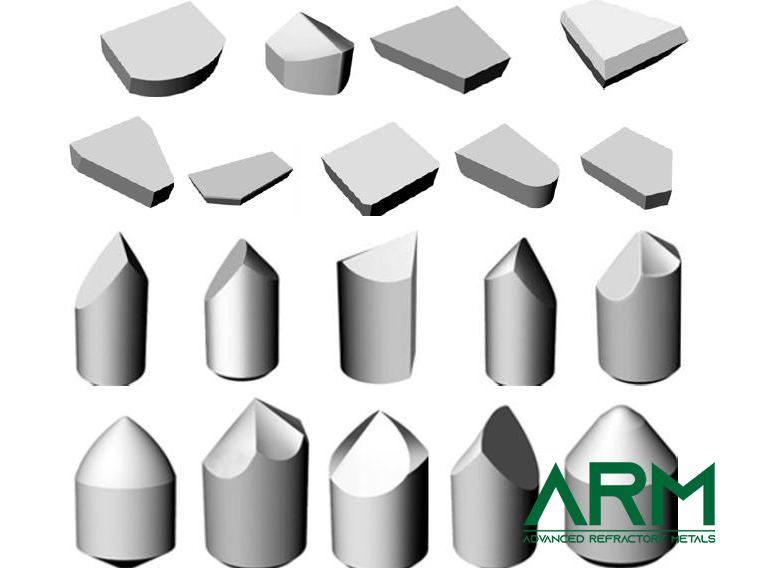

| Tungsten Carbide Powder | ≥99.5% | 0.4–10 μm | Cutting tools, wear parts, hard-facing |

| Tungsten Alloy Powder | 85–97% W | Custom | Shielding, aerospace, military |

Note: Custom specifications available upon request.

Packaging of Tungsten Powder

Our Tungsten Powder is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Related reading:

3 Main Factors Affecting The Quality Of Tungsten Powder

Tungsten Powder Uses & Producing Methods

Factors Affecting The Performance Of Tungsten Powder

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-