Descriptions of Molybdenum

Molybdenum metal is a silvery white, very hard transition metal, but is softer and more ductile than tungsten. Its main characteristics are durability, strength, and resistance to corrosion and high temperatures. Molybdenum is a metal used as raw material in order to obtain alloys, among which more resistant steel stands out. Approximately two-thirds of this metal is used for this purpose, also known as inox, with contents up to 6%.

Advanced Refractory Metals is a leading supplier of molybdenum products. We offer low pricing and great lead times on all our materials, and we're capable of supplying custom materials per any specs/drawings you provide us with.

List Of Our Molybdenum Products

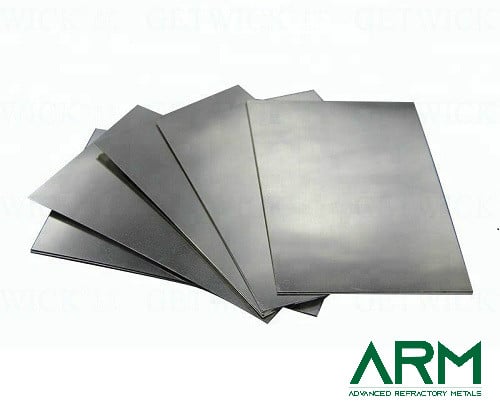

| Molybdenum Sheet | ||

| .003″ x 12″ x 36″ | .020″ x 12″ x 36″ | .060″ x 12″ x 36″ |

| .005″ x 12″ x 36″ | .025″ x 12″ x 36″ | .070″ x 12″ x 36″ |

| .010″ x 12″ x 36″ | .030″ x 12″ x 36″ | .090″ x 12″ x 36″ |

| .012″ x 12″ x 36″ | .040″ x 12″ x 36″ | .100″ x 12″ x 36″ |

| .015″ x 12″ x 36″ | .050″ x 12″ x 36″ | .125″ x 12″ x 36″ |

| Molybdenum Plate | ||

| .187″ x 12″ x 36″ | .500″ x 12″ x 36″ | 1″ x 12″ x 36″ |

| .250″ x 12″ x 36″ | .625″ x 12″ x 36″ | 1.25″ x 12″ x 36″ |

| .375″ x 12″ x 36″ | .750″ x 12″ x 36″ | |

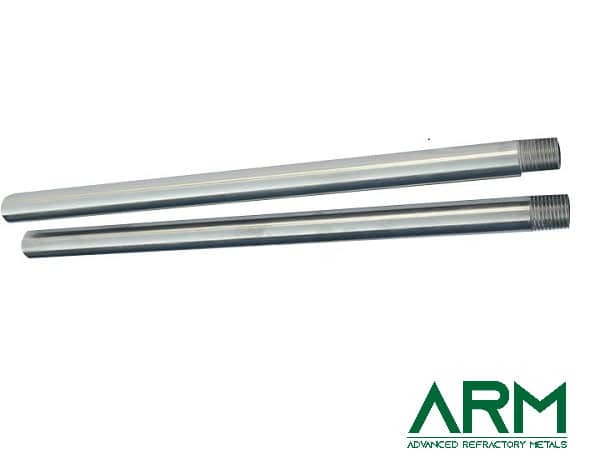

| Molybdenum Rod & Molybdenum Bar | ||

| .060″ x diameter x r/l’s | .250″ x diameter x r/l’s | .875″ x diameter x r/l’s |

| .062″ x diameter x r/l’s | .3125″ x diameter x r/l’s | 1.00″ x diameter x r/l’s |

| .070″ x diameter x r/l’s | .375″ x diameter x r/l’s | 1.250″ x diameter x r/l’s |

| .080″ x diameter x r/l’s | .437″ x diameter x r/l’s | 1.500″ x diameter x r/l’s |

| .100″ x diameter x r/l’s | .500″ x diameter x r/l’s | 1.750″ x diameter x r/l’s |

| .125″ x diameter x r/l’s | .625″ x diameter x r/l’s | 2.000″ x diameter x r/l’s |

| .1875″ x diameter x r/l’s | .750″ x diameter x r/l’s | 2.250″ x diameter x r/l’s |

| Molybdenum Wire | ||

| .002″ diameter x coil | .006″ diameter x coil | .030″ diameter x coil |

| .003″ diameter x coil | .010″ diameter x coil | .035″ diameter x coil |

| .004″ diameter x coil | .020″ diameter x coil | .040″ diameter x coil |

| .005″ diameter x coil | .025″ diameter x coil | .050″ diameter x coil |

| Molybdenum Tube & TZM Tube | ||

| .125” od x .015” wall x 36” long | .312” od x .030” wall x 36” long | .750” od x .050” wall x 36” long |

| .188” od x .020” wall x 36” long | .375” od x .025” wall x 36” long | 1.00” od x .050” wall x 36” long |

| .250” od x .020” wall x 36” long | .500” od x .030” wall x 36” long | |

| Molybdenum Strip (Thickness) | ||

| 0.01-0.03 mm | 0.03-0.06 mm | 0.06-0.10 mm |

| 0.10-0.15 mm | ||

| Molybdenum Foil | ||

| .001” | .002” | .003” |

| .004” | .005” | .006” |

| .007” | .008” | .009” |

| Molybdenum Disc & Molybdenum Square | ||

| 7 ~ 100mm Diameter | 0.25 ~ 4.0mm Thickness | |

| Molybdenum Spraying Wire | ||

| 3.17 mm | 2.3 mm | |

| Molybdenum Lanthanum Wires (Mo-La wires) | ||

| 0.2mm-4.0mm Dia. x L | ||

| Molybdenum Heating Elements (Diameter) | ||

| 3.0 mm | 4.0 mm | 5.0 mm |

| 6.0 mm | 7.0 mm | 8.0 mm |

| 9.0 mm | ||

| Molybdenum Boat | ||

| 0.3-30mm T | 10-500mm W | 50-1000mm L |

| Molybdenum Crucible (Capacity) | ||

| 1000 ml | 100 ml | 10 ml |

| 15 ml | 20 ml | 25 ml |

| 35 ml | 45 ml | 55 ml |

| 5 ml | 75 ml | |

| Molybdenum Electrode | ||

| (14-20)×(14-20)×L, L < 500 mm | (3 – 25)×(50 -500)×L, L < 800 mm | (f20 – f100)×L mm |

| Molybdenum Tray | ||

| Molybdenum (Mo) Mandrel | ||

| Molybdenum Trioxide (MoO3) | ||

| -325mesh | -100mesh | -200mesh |

| Molybdenum Metal Powder (Particle size) | ||

| 2 – 3μm | 50nm | |

| Molybdenum Powder for Thermal Spraying | ||

| -75 +38 µm | -75 +30 µm | -45 +16 µm |

| Molybdenum Disulfide (MoS2) | ||

| 1.0-1.5 μm | ||

| Mo-La Alloy (Molybdenum Lanthanum Alloy) | ||

| TZM Alloy (TZM Molybdenum) | ||

| Molybdenum Niobium Alloy Ingots (Mo-Nb Alloy) | ||

| Ion Implantation Components (TZM Alloy) | ||

| Molybdenum Fastener | ||

| Molybdenum Heat Shield | ||

| Molybdenum Spinning Nozzle | ||

| Ion Implantation Components (Molybdenum) | ||

* Specific lengths and sizes available upon request.

Applications of Molybdenum

* Filaments

* Contacts

* Heat Shields

* Jet Tabs

* Rocket Nozzles

* Brazing Fixtures

* Boring Bars

* Tools

* Missile Parts

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-