MU0086 Molybdenum Electrode

Descriptions of Molybdenum Electrode

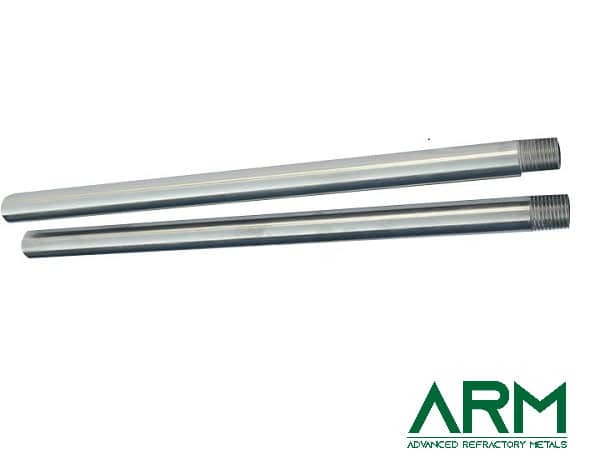

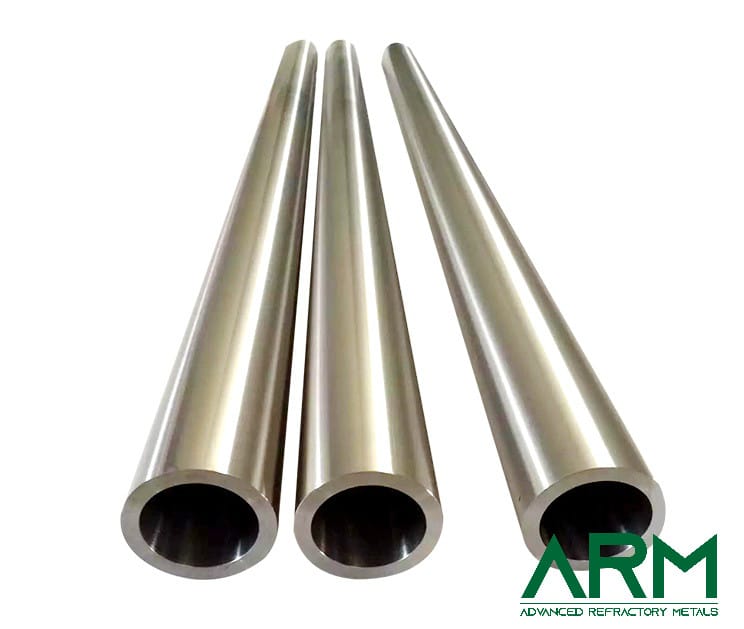

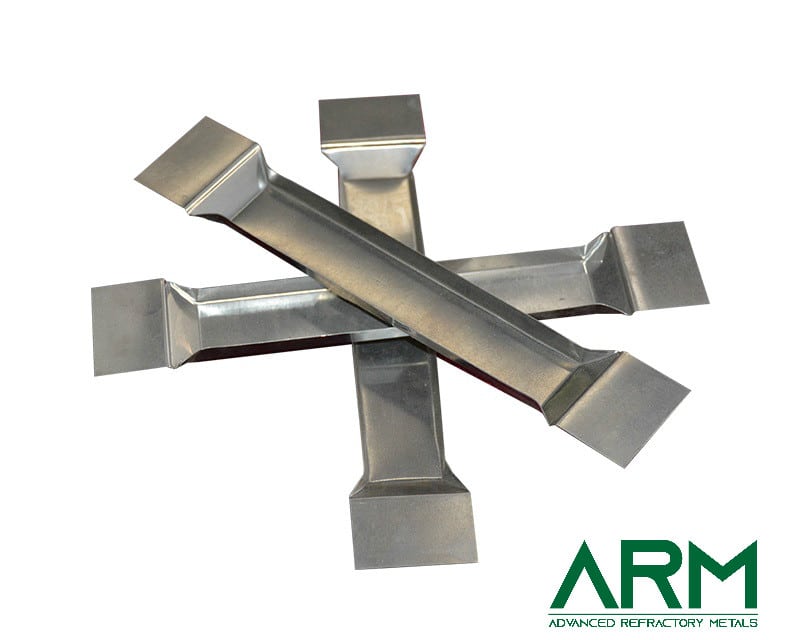

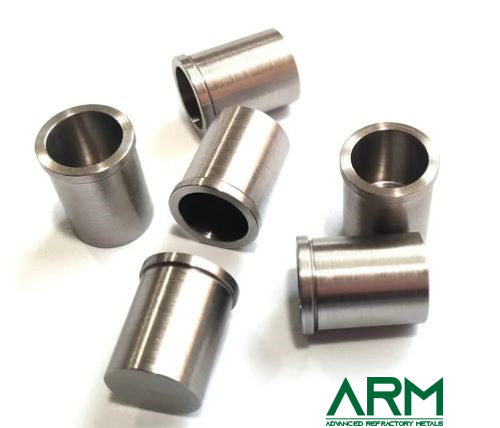

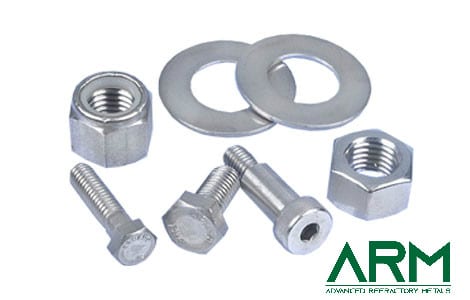

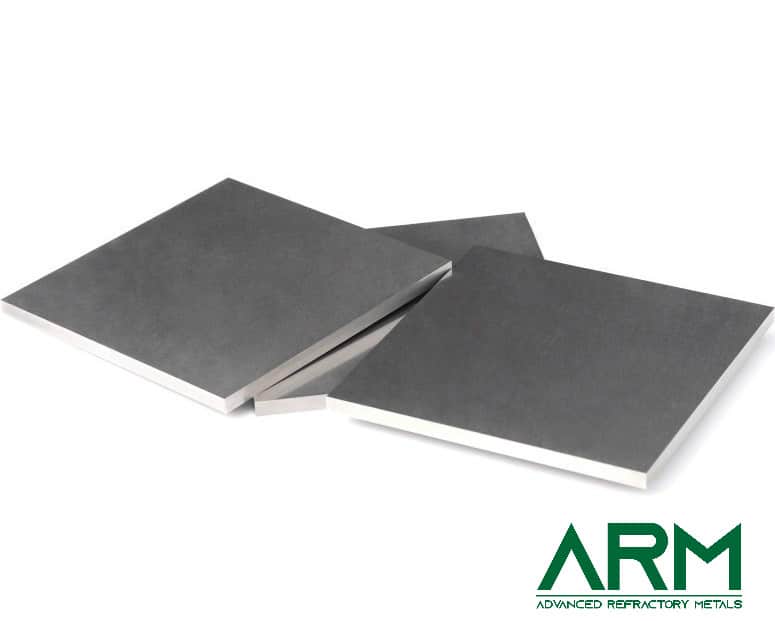

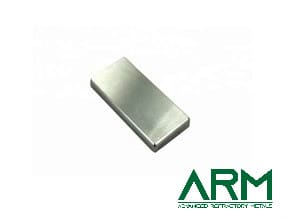

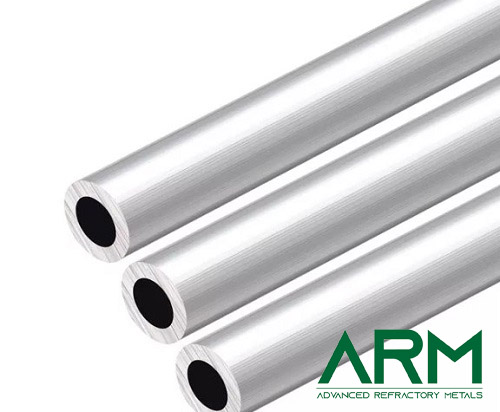

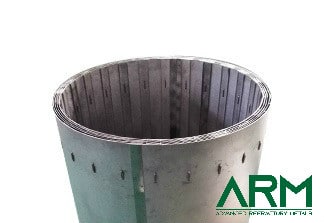

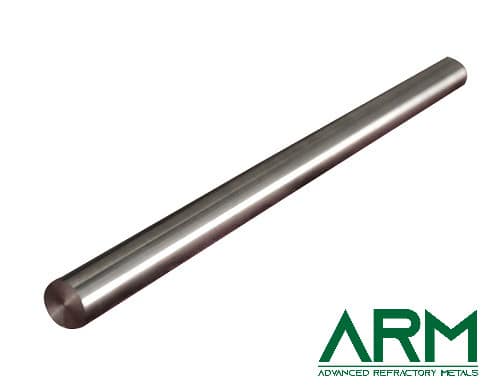

Molybdenum electrodes are made through isostatic pressing and can be forged to various specifications after undergoing sintering and shaping in medium frequency furnaces. Glass melting electrodes must withstand extremely high temperatures and aggressive glass melts. We can also offer different kinds of molybdenum electrodes as your requirements.

Specifications of Molybdenum Electrode

| Product Name | Appearance | Purity | Density | Unite Weight | Dimension (mm) |

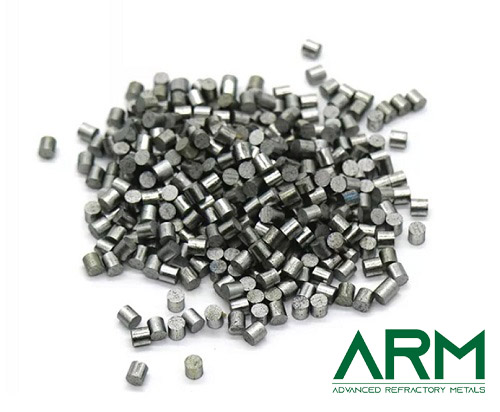

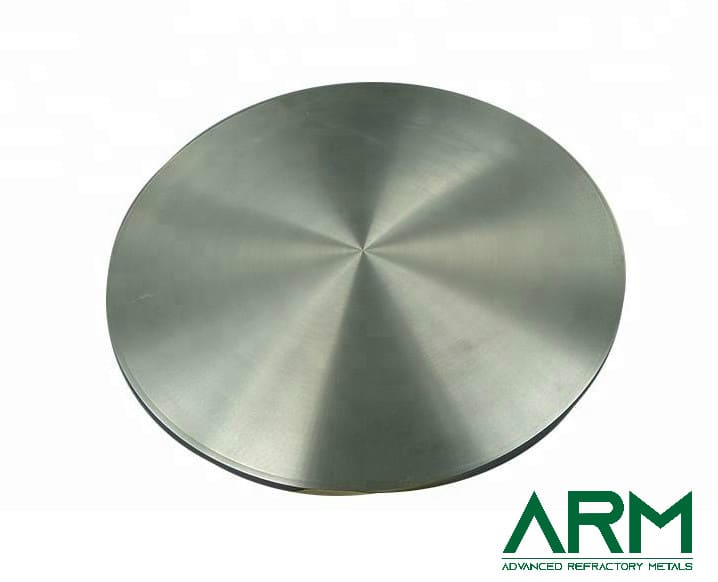

| Molybdenum Electrode | Silver gray metallic luster | > 99.95% | >9.8 g/cc | -- | (14-20)×(14-20)×L, L < 500 |

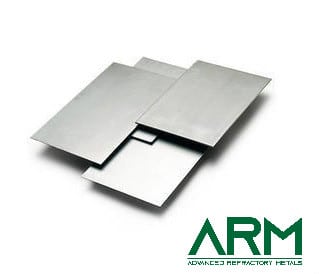

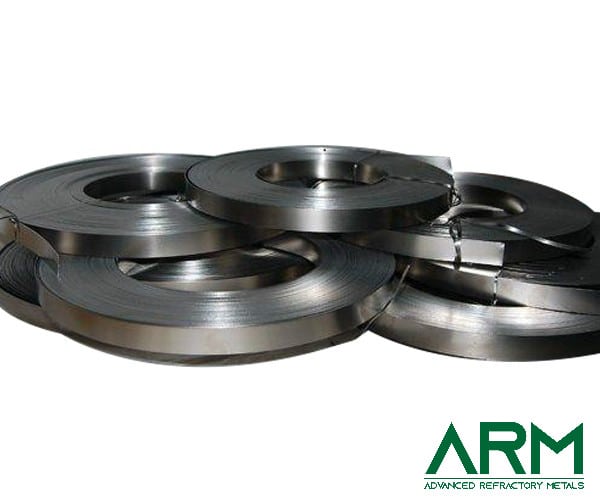

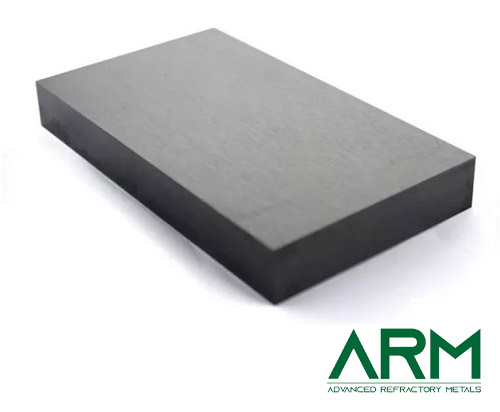

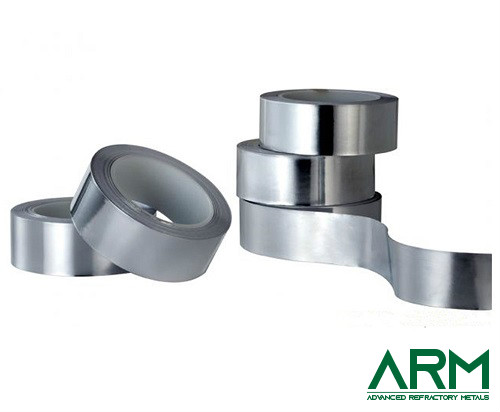

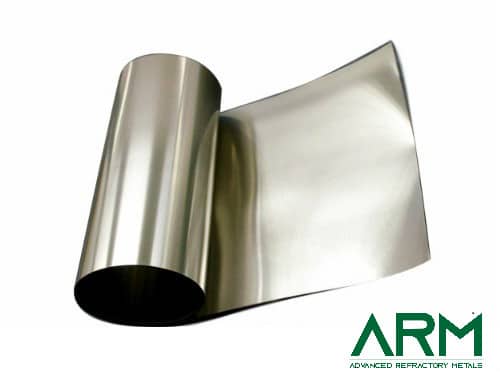

| Molybdenum Electrode Plate | Dark brown. It presents silver gray metallic luster if washed by the alkali | > 99.95% | >10.15 g/cc | <=40 kgs | (3 - 25)×(50 -500)×L, L < 800 |

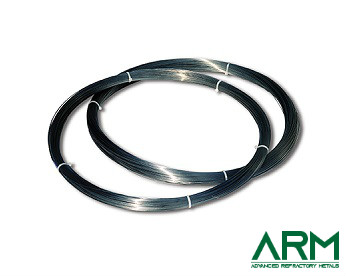

| Molybdenum Electrode Bar | Bright silver gray metallic luster. | > 99.93% | > 10.15 g/cc | < 70kgs | (f20 - f100)×L |

Applications of Molybdenum Electrode

* Used as electro-heat equipment of the glass fiber kiln.

* Electrode plate (3~25mm x 50~500mm x L L<800mm) can be used as various kinds of heating equipment of glass fiber kiln, liquid-flow hole panel, etc.

* Electrode rod (20~100mm diameter x L) is mainly used as the furnace, electric boosting glass kiln electrode, etc.

Packaging of Molybdenum Electrode

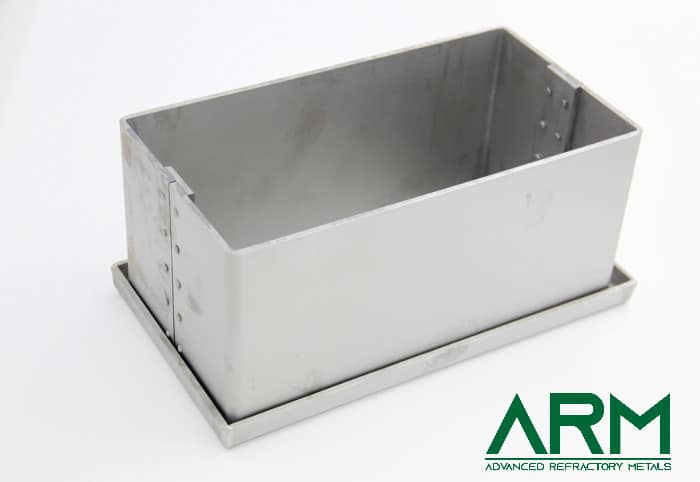

Our molybdenum electrodes are wrapped in foam and packaged in plywood cases to ensure safe storage and transportation.

Related reading:

Influence Of Molybdenum Electrodes On The Quality Of Glass Products

Impurities In Glass Materials Affect Molybdenum Electrode Service Life

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-