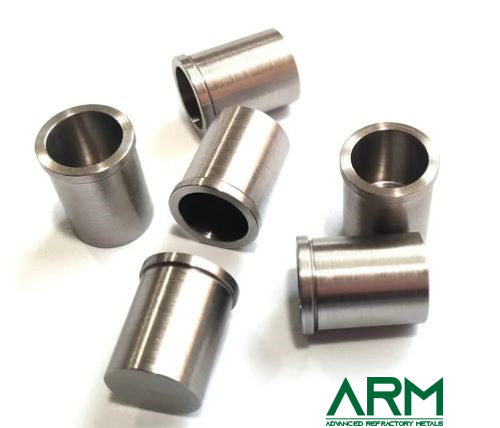

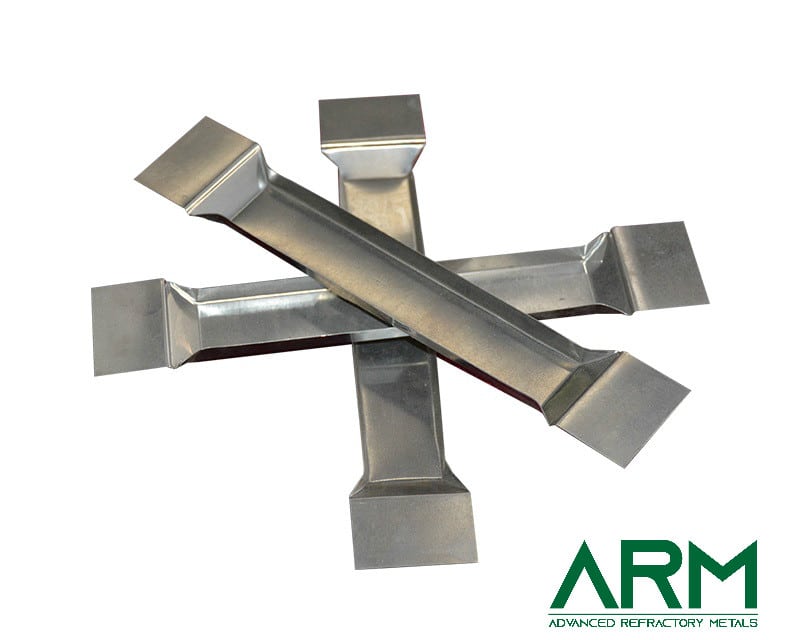

MU0085 Molybdenum Crucible

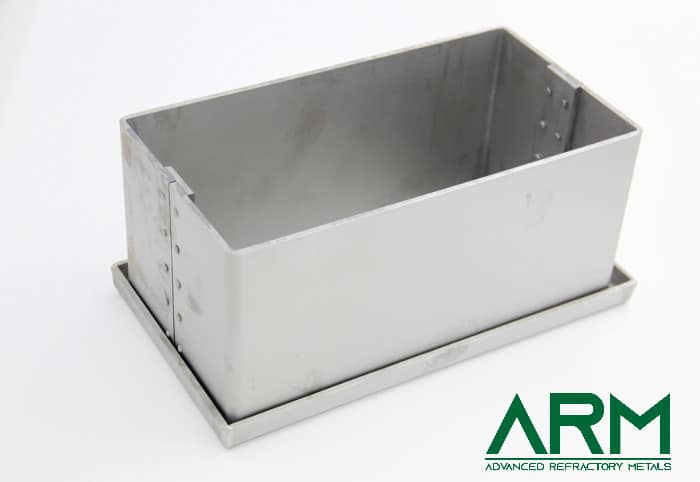

Molybdenum crucibles can be produced with sintering purposes (density of 9.8-10g/cc) or forging purposes (up to 10.2g/cc). Customized shapes for Molybdenum crucibles include, but are not limited to, oval, tapered, bottomless, or round mouth.

Descriptions of Molybdenum Crucible

Molybdenum crucibles can be produced with sintering purposes (density of 9.8-10g/cc) or forging purposes (up to 10.2g/cc). Customized shapes for Molybdenum crucibles include, but are not limited to, oval, tapered, bottomless, or round mouth. Advanced Refractory Metals can provide customized molybdenum crucibles according to customer's drawings.

Specifications of Molybdenum Crucible

| Condition | Size (mm) | Tolerance (mm) | ||

| Diameter (mm) | Height (mm) | Diameter (mm) | Height (mm) | |

| Sintering | 10-500 | 10-600 | +/-5 | +/-5 |

| Forging | 10-130 | 10-200 | +/-1 | +/-2 |

* Molybdenum Straight Wall Crucibles

| Item Code | Capacity | Outside Diameter | Depth |

| MO-C-1000 | Cap (ml), 1000 | Outside Dia (mm), 127 | Depth (mm), 89 |

| MO-C-100 | Cap (ml), 100 | Outside Dia (mm), 59 | Depth (mm), 45 |

| MO-C-10 | Cap (ml), 10 | Outside Dia (mm), 27 | Depth (mm), 22 |

| MO-C-15 | Cap (ml), 15 | Outside Dia (mm), 33 | Depth (mm), 22 |

| MO-C-20 | Cap (ml), 20 | Outside Dia (mm), 33 | Depth (mm), 29 |

| MO-C-25 | Cap (ml), 25 | Outside Dia (mm), 45 | Depth (mm), 22 |

| MO-C-35 | Cap (ml), 35 | Outside Dia (mm), 46 | Depth (mm), 29 |

| MO-C-45 | Cap (ml), 45 | Outside Dia (mm), 46 | Depth (mm), 34 |

| MO-C-55 | Cap (ml), 55 | Outside Dia (mm), 47 | Depth (mm), 41 |

| MO-C-5 | Cap (ml), 5 | Outside Dia (mm), 21 | Depth (mm), 18 |

| MO-C-75 | Cap (ml), 75 | Outside Dia (mm), 51 | Depth (mm), 41 |

-

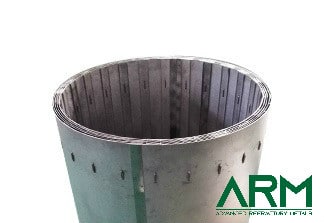

Pressed and Sintered Crucibles: Made by pressing and sintering molybdenum powder into the final shape, these are among the most popular and widely used crucibles.

-

Spin-formed Crucibles: Created by hot spin-forming large molybdenum plate blanks into the desired geometry, ideal for specific shapes and sizes.

-

Milled Crucibles: Machined from material blanks to achieve precise dimensions, these crucibles are highly popular for their accuracy and customizability.

-

Welded Crucibles: Designed for large crucibles with thinner walls, welded molybdenum crucibles are recommended for applications requiring lightweight and durable solutions.

Applications of Molybdenum Crucible

Molybdenum crucible is mainly used in metallurgy industry and mechanism process industry, and it is a kind of indispensability material in the rare earth smelting industry. Molybdenum crucibles are more frequently used in crystalloid materials and other burgeoning high technology industry.

Packaging of Molybdenum Crucible

Our molybdenum crucibles are wrapped in foam and packaged in plywood cases to ensure safe storage and transportation.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-