MU0083 Molybdenum Tube & TZM Tube

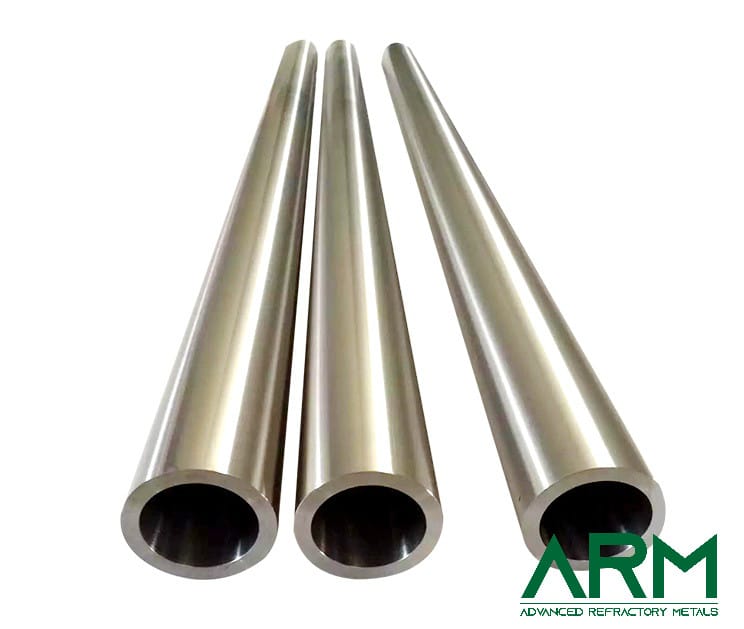

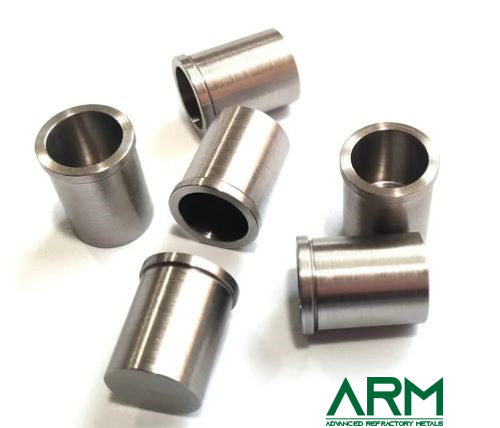

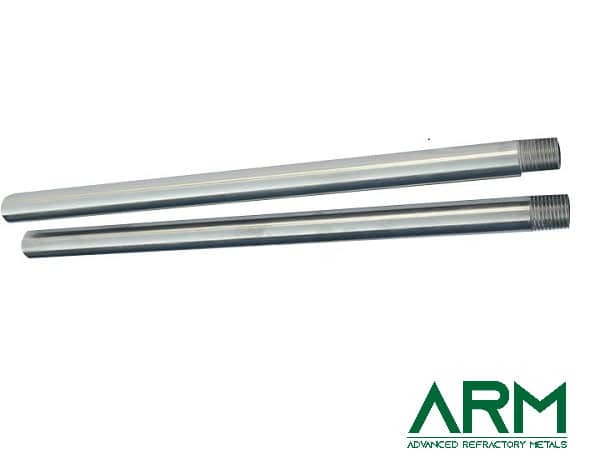

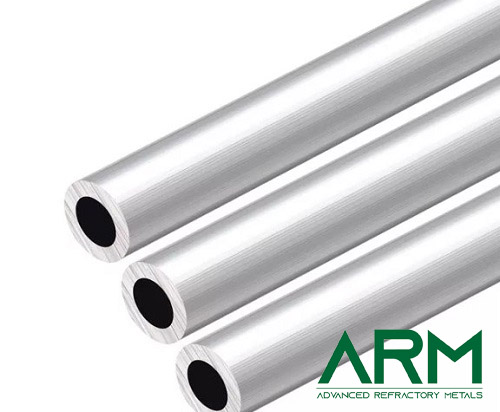

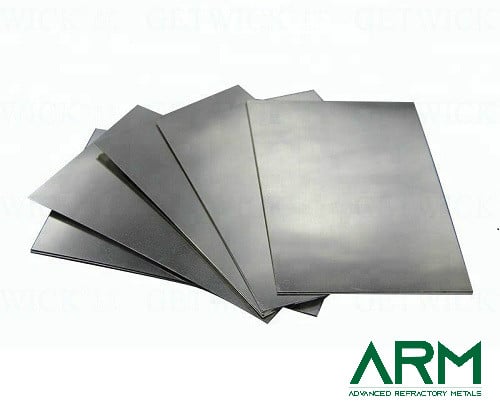

We provide molybdenum tube from forged rods and sintering directly. Molybdenum tube with OD smaller than 60mm are mostly machined and gun drilled from the forged rod, the tube with a larger diameter are sintered per size directly.

Descriptions of Molybdenum Tube

We provide molybdenum tube from forged rods and sintering directly. Molybdenum tube with OD smaller than 60mm are mostly machined and gun drilled from the forged rod, the tube with a larger diameter are sintered per size directly. The process methods of tubes and crucibles are always for saving cost and according to customer’s requirement.

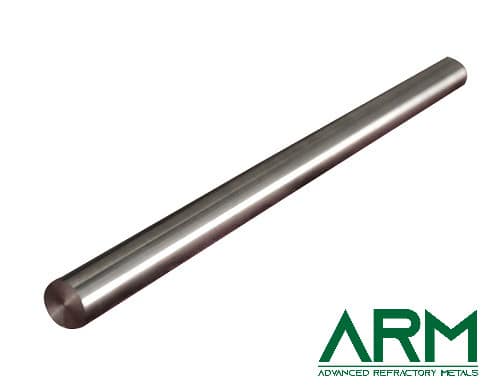

* TZM Tube

In addition to Moly tube, we also supply Molybdenum alloy tubes including TZM tubing and La2O3 doped Moly (Mo-La) tubing. TZM tubes and Mo-La tubes have high creep resistance, recrystallization temperature, and thermal stability.

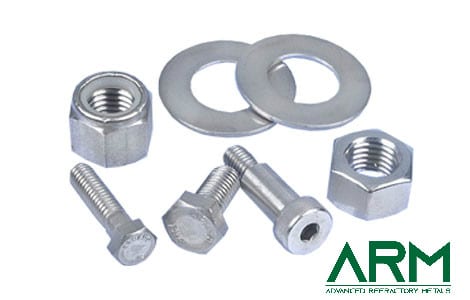

Specifications of Molybdenum Tube

|

Size |

Customized |

|

Material |

Mo≥99.95% & TZM |

|

Standard |

ASTM B387 |

|

Density |

9.8 - 10.2 g/cc |

|

Surface |

Polished, Chemical cleaned |

Types of Molybdenum Tube

-

Seamless Molybdenum Tubes: Continuous, smooth tubes without seams, offering uniformity and high strength.

-

Welded Molybdenum Tubes: Made by welding, typically for larger sizes, offering flexibility in manufacturing.

-

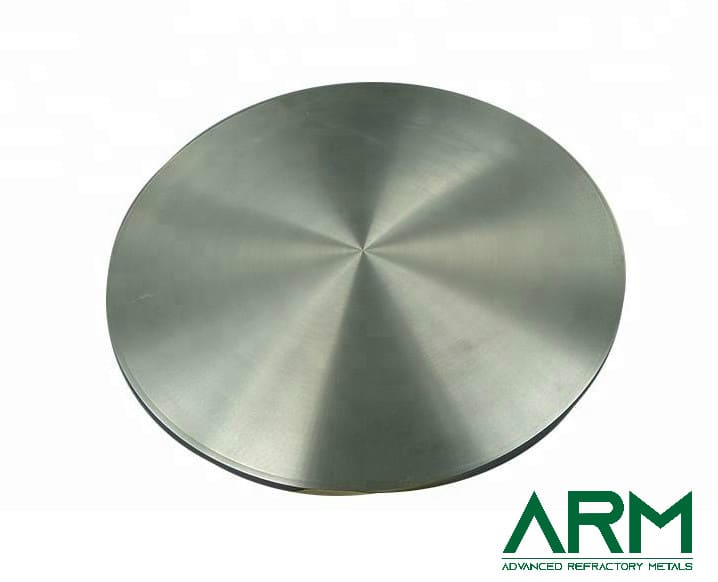

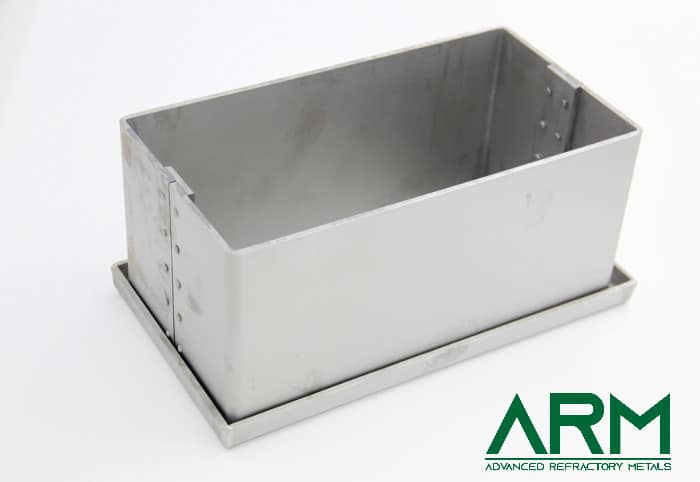

Pressed and Sintered Tubes: Produced by pressing molybdenum powder and sintering it into shape, commonly used for larger crucibles.

-

Milled Tubes: Made from material blanks that are processed into final tube shapes, often used for smaller tubes.

-

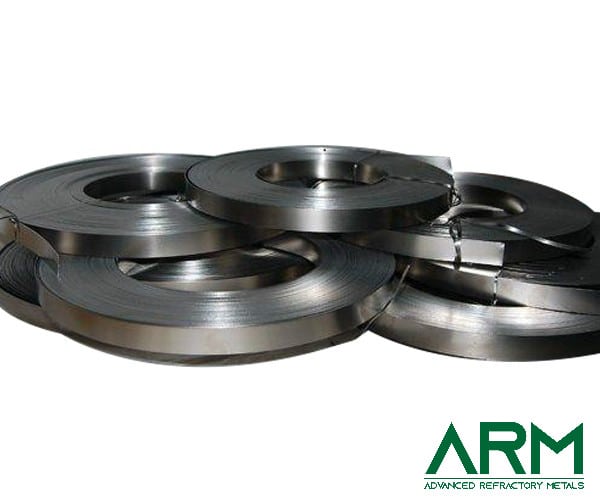

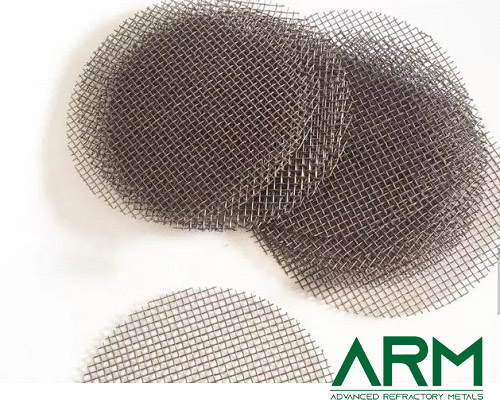

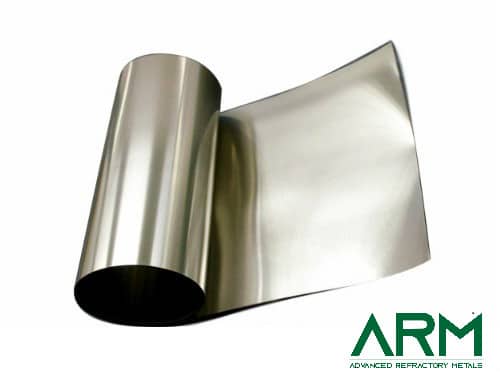

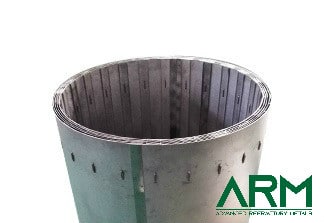

Riveted Tubes: Manufactured from molybdenum sheet and strip, commonly used in heat shielding applications.

-

Welding and Riveting Liner Tubes: Used for large tubes with thinner walls, providing strength and stability in demanding environments.

Applications of Molybdenum Tube

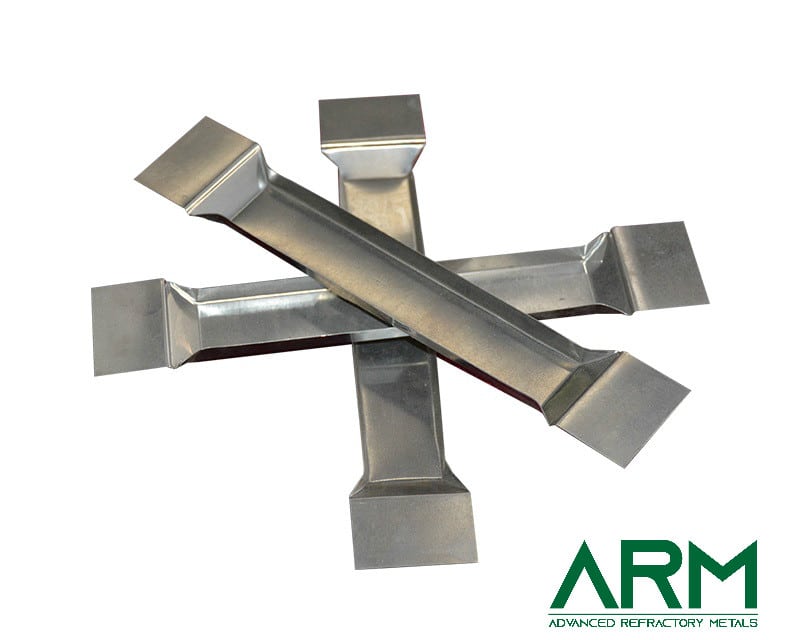

* Molybdenum tube (pipe) can be used at service temperature up to 1,800 degrees.

* Used in components of the electron tube, heaters of high-temperature furnaces, thermocouple retainers.

Packaging of Molybdenum Tube

Our Mo tubes and Mo alloy tubes carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (required)

-

Attachment (Optional)

No file chosen

-