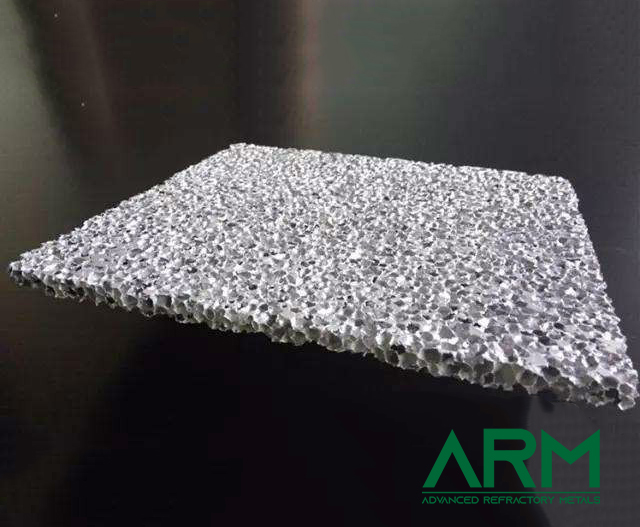

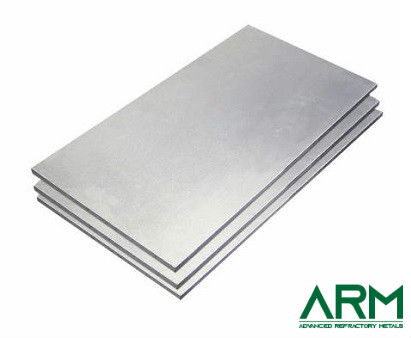

AL1812 Aluminum Foam

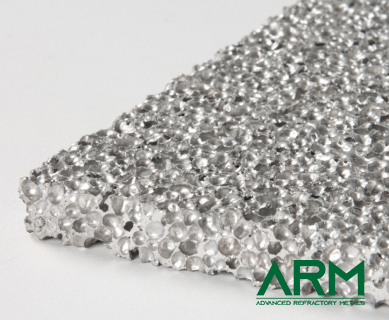

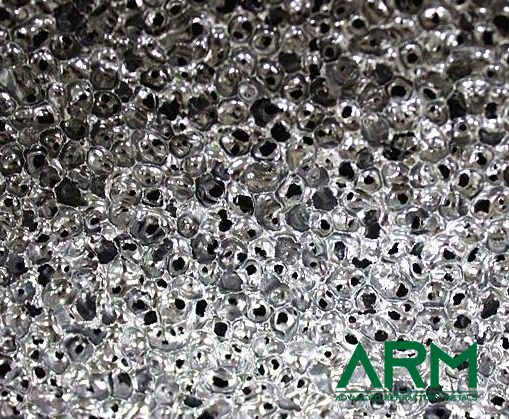

The metal material containing the foamed pores has a higher porosity and a larger pore size of up to 7 mm than the generally sintered porous metal. Since the metal foam is a two-phase composite composed of a continuous phase of a metal matrix skeleton and a dispersed phase of a pore or a continuous phase, its properties depend on the metal matrix used, the porosity and the pore structure, and are affected by the preparation process.

| Catalog No. | AL1812 |

|---|---|

| Material | Aluminum |

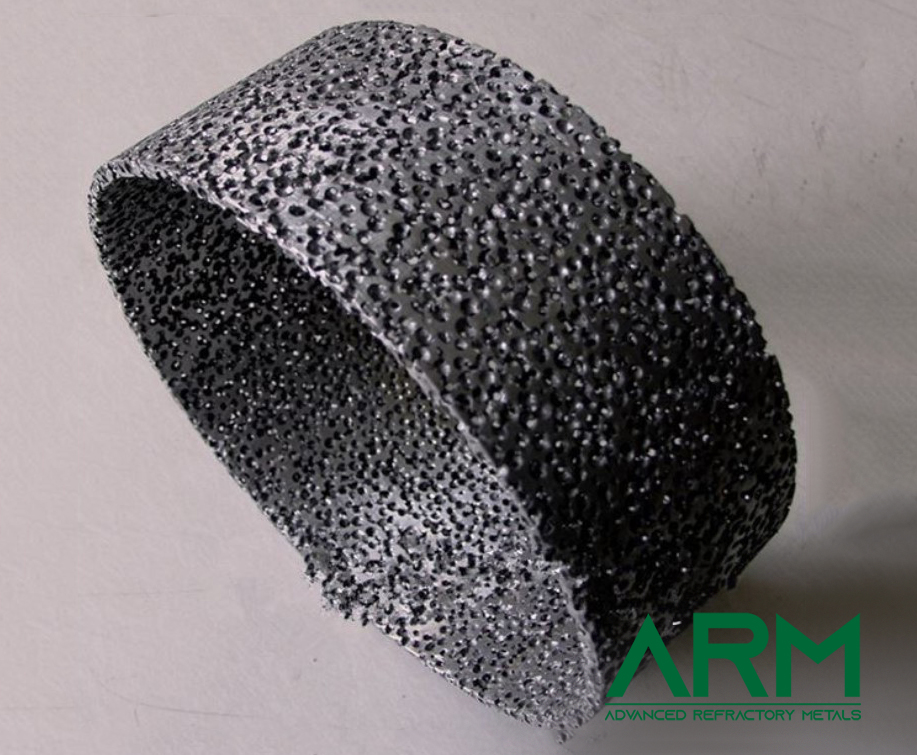

| Shape | Sheet, belt or customized |

| Thickness | 0.3-100mm |

Aluminum Foam Description

The metal material containing the foamed pores has a higher porosity and a larger pore size of up to 7 mm than the generally sintered porous metal. Since the metal foam is a two-phase composite composed of a continuous phase of a metal matrix skeleton and a dispersed phase of a pore or a continuous phase, its properties depend on the metal matrix used, the porosity and the pore structure, and are affected by the preparation process.

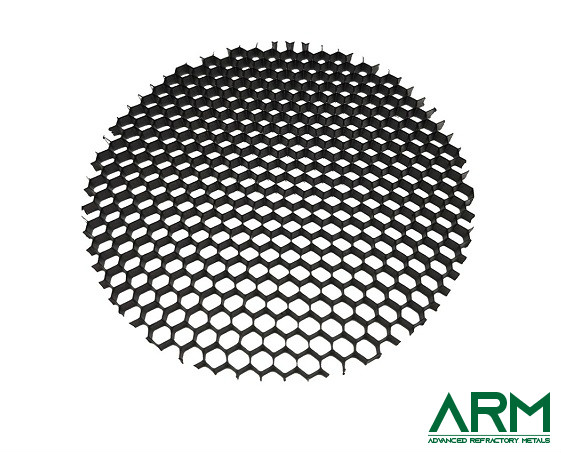

Generally, the mechanical properties of foamed metal decrease with increasing porosity, and the electrical conductivity and thermal conductivity decrease exponentially. When the metal foam is subjected to pressure, the foamed metal has excellent impact energy absorption characteristics due to an increase in the area of the force caused by the collapse of the pores and the strain hardening effect of the material.

Foamed aluminum and its alloys are light in weight, with sound absorption, heat insulation, vibration damping, shock absorption, and electromagnetic waves. They are suitable for impact protection of missiles, aircraft and their recycling parts, automobile buffers, electromechanical vibration damping devices, and pulses.

Aluminum Foam Specification

| Density | 0.2g/cm3 to 0.6g/cm3 |

| Void ratio | 75% to 90% |

| Energy absorption | 8J/m3~30J/m3 |

| Compressive strength | 3Mpa-17Mpa |

| Bending strength | 3Mpa-15Mpa |

| Aperture | uniform distribution 1-10mm, main aperture 4-8mm |

| No. |

Relative gravity(g/cm3) |

Size |

Application |

|

1 |

0.25~0.4 |

2400×800×h (customized) |

Sound absorbing material, marble composite board, interior and exterior decorative composite board, heat insulation wall material |

|

2 |

0.4~0.6 |

Impact-resistant material, composite body panel, sound insulation material, marble composite board, interior, and exterior decorative composite board |

|

|

3 |

>0.6 |

Impact resistant material |

Aluminum Foam Applications

Aluminum foam is used in concert halls, theaters, recording studios, studios, dance halls, gymnasiums, subway stations, waiting rooms, waiting rooms, hotel lobbies, large shopping malls, exhibition halls, office halls, newspaper rooms, computer rooms, etc. Aluminum foam has the effect of sound reverberation in these positions.

For pipe mufflers, muffling elbows, and static pressure boxes, especially suitable for clean workshops, food production workshops, pharmaceutical factories, precision instrument manufacturing workshops, laboratories, wards, operating rooms, restaurant canteen, ship cabin, auxiliary engine room, cabin and other places The air conditioning and ventilation equipment play the role of noise reduction and noise reduction.

In the city light rail, elevated roads, traffic trunks, highways, railways, overpasses, cooling towers, open-air high-voltage substations, concrete mixing plants, and other places to play the role of sound insulation sound barrier.

In diesel engines, generators, motors, internal combustion engines, freezers, air compressors, airplanes, trains, automobiles, ships, boilers, forging hammer equipment, fans and other equipment, sound absorption, sound insulation, and noise reduction can be performed.

Aluminum Foam Packaging

Our aluminum foam is carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-