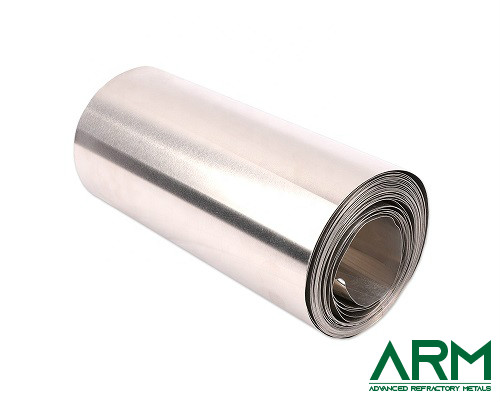

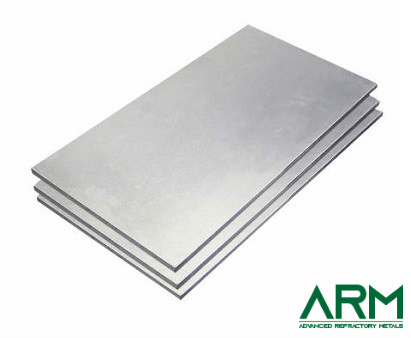

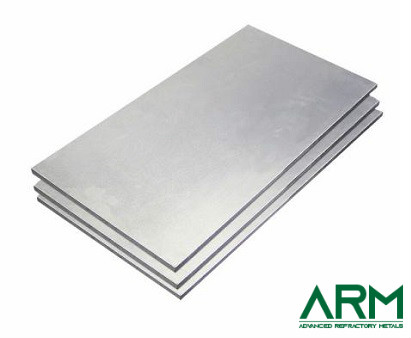

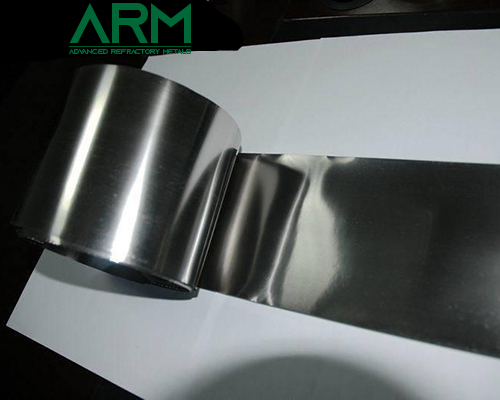

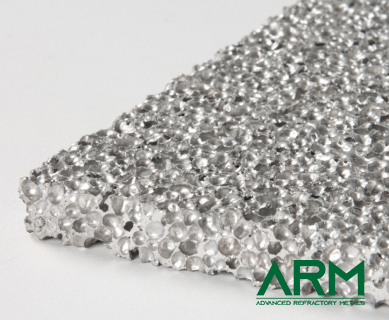

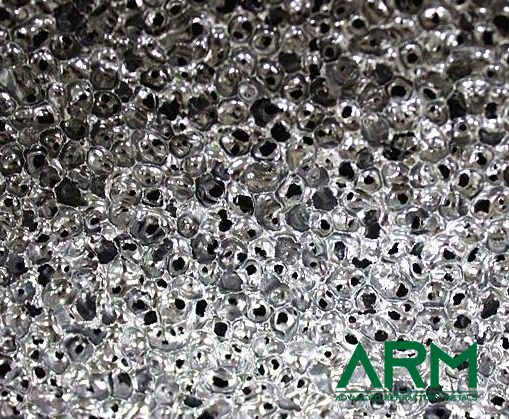

ALF1462 Aluminum Alloy 1100 Foil

A commercially pure aluminum, Aluminum alloy 1100 contains no more than one percent of other chemical elements. Aluminum Alloy 1100 is standard aluminum alloy containing a minimum of 99.0% aluminum.

Descriptions of Aluminum Alloy 1100 Foil

A commercially pure aluminum, Aluminum alloy 1100 contains no more than one percent of other chemical elements. Aluminum Alloy 1100 is standard aluminum alloy containing a minimum of 99.0% aluminum. It is formable, weldable, and its ability to take a form is excellent. Typical markets include chemical equipment, reflectors, heat exchangers, architectural applications, and many more.

Advanced Refractory Metals is a leading supplier of Aluminum Alloy 1100 Foil. We offer competitive pricing and great lead times on all our materials, and we’re capable of supplying custom materials per any specs/drawings you provide us with.

Specifications of Aluminum Alloy 1100 Foil

|

Aging: |

This material will not age, but can oxidize when left in an extremely damp environment and/or when Exposed to extreme temperatures in both hot and cold environments. |

|

Annealing: |

Annealing, which may be necessary after cold working. The material is heated to 650°F and then air cooled. |

|

Applications: |

Commonly used as tapes, fin stock, heat exchanger fins, tags, and names plates, Commercial filters, decorative applications, giftware, and reflectors, and in sheet metal work. |

|

ASTM Standards: |

B479 |

|

Cold Working: |

This is a excellent alloy for cold working because of the good malleability in the annealed temper. It can easily be bent, drawn, or spun into a variety of applications. |

|

Finish: |

Standard Finishes |

|

Forging - Hot Working: |

Hot working can be conducted when needed. The alloy can be hot forged. |

|

Forming - Welding: |

Forming either hot or cold is readily accomplished with this alloy. In the annealed condition this alloy can be cold worked extensively without an intermediate anneal. Easily welded by all conventional methods. |

|

Hardening: |

Hardens during cold working only. |

|

Heat Treatment: |

This alloy does not respond to heat treatment other than to anneal the material into a soft or O Temper material. |

|

Other Physical Properties: |

Electrical conductivity is 53% of copper. |

|

Principal Design Features: |

This alloy is 99.0% min pure aluminum with excellent ability to be formed and worked. |

|

QQA Standards: |

1876 |

|

Temper: |

This material is available in a variety of tempers. |

|

Thickness: |

0.0005 to 0.064 in |

|

Width: |

0.375 to 60 in |

Chemical Properties

|

Aluminum (Al): |

99.00% |

|

Chromium (Cr): |

- |

|

Copper (Cu): |

0.05 to 0.20% |

|

Iron (Fe): |

- |

|

Magnesium (Mg): |

- |

|

Manganese (Mn): |

0.05% |

|

Other Total: |

0.15% |

|

Silicon (Si): |

0.95% (Si+Fe) |

|

Titanium (Ti): |

- |

|

Zinc (Zn): |

0.10% |

Mechanical Properties

|

Elongation (Annealed): 1 |

35 |

|

Elongation (H12): |

12 |

|

Elongation (H14): |

9 |

|

Elongation (H16): |

6 |

|

Elongation (H18): |

5 |

|

Other Mechanical Properties: |

Shear strength values are: “O” (annealed) temper 9 KSI, H12 temper 10 KSI, H18 temper 13 KSI. |

|

Tensile Strength (Annealed): 2 |

13 x 1000 psi |

|

Tensile Strength (H12): |

16 x 1000 psi |

|

Tensile Strength (H14): |

18 x 1000 psi |

|

Tensile Strength (H16): |

21 x 1000 psi |

|

Tensile Strength (H18): |

24 x 1000 psi |

|

Yield Strength (Annealed): 3 |

5 x 1000 psi |

|

Yield Strength (H12): |

15 x 1000 psi |

|

Yield Strength (H14): |

17 x 1000 psi |

|

Yield Strength (H16): |

20 x 1000 psi |

|

Yield Strength (H18): |

22 x 1000 psi |

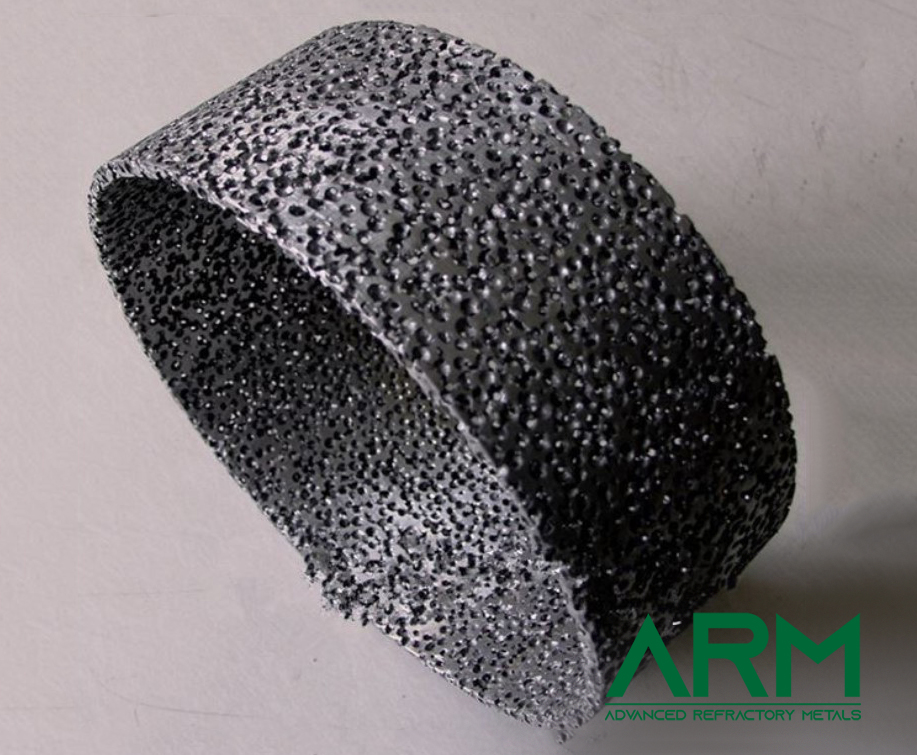

Packaging of Aluminum Alloy 1100 Foil

Our Aluminum Alloy Foil is carefully handled to minimize damage during storage and transportation and to preserve the quality of our product in its original condition.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-