Applications of Molybdenum and Molybdenum Alloys

Applications of Molybdenum and Molybdenum Alloys in the Material Processing Industry

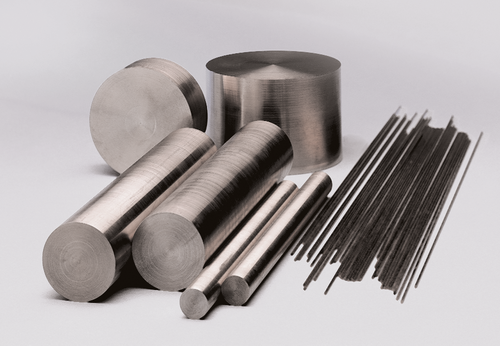

Molybdenum and molybdenum alloys have good thermal conductivity, electrical conductivity, low thermal expansion coefficient, high-temperature strength, low vapor pressure, and wear resistance. As a result, they have become important materials for electronic and power equipment manufacturing, metal material processing, glass manufacturing, high-temperature furnace structural parts manufacturing, aerospace, and defense industry applications. In this article, we'll take a deeper look at the applications of molybdenum and molybdenum alloys in the material processing industry.

Applications of Molybdenum and Molybdenum Alloys

The main application areas of molybdenum and molybdenum alloys in the material processing industry are as follows:

1. Applications of Molybdenum and Molybdenum Alloys in Hot-Working Molds

In the aviation and aerospace fields, molybdenum alloys are mainly used to make molds for high-temperature forging engine parts.

2. Applications of Molybdenum and Molybdenum Alloys in Molten Metal Processing

Cast aluminum plants use molybdenum to suppress the hot cracking of their processed materials, that is, usually use TZM (titanium-zirconium-molybdenum) alloy cores in the processed materials that are prone to hot cracks, which can also avoid the hot cracking of the materials. The use of TZM and MHC alloys can also improve the rapid solidification capability of processing equipment. Tungsten-molybdenum alloy has the same corrosion resistance, which can obviously reduce manufacturing costs. Therefore, Mo-25%W and Mo-30%W alloy materials suitable for promotion and application in impeller pump units and molten zinc pipe systems have been developed.

3. Applications of Molybdenum and Molybdenum Alloys in Thermal Spraying

The piston ring can be thermally sprayed with molybdenum. The method is to mix molybdenum powder with a binder containing nickel (Ni) and chromium (Cr) and then spray the mixture on the piston in a plasma manner. The coating can be pure molybdenum or molybdenum alloy mixed powder, which is resistant to wear and corrosion, so it is suitable for papermaking applications.

Moreover, molybdenum powder can also be mixed with different content of nickel, chromium, boron, and silicon powder to form different powder mixtures, but the spray powder requires good fluidity, and the thermal spray powder should generally be spherical or nearly spherical after spraying.

In addition, the mixed powder of molybdenum and molybdenum alloy can also be used for the plasma nozzle to densify into pre-alloyed powders of different quality, more wear, and corrosion resistance.

4. Applications of Molybdenum and Molybdenum Alloys in Chemical Treatment

The use of molybdenum as electrode material for glass melting processing can also improve the processing capacity of traditional furnaces. Because molybdenum has high-temperature strength and thermal stability, it is suitable for high-temperature furnace components. For example, molybdenum and molybdenum alloys are mostly used as materials for hot isostatic pressing (HIP) devices, heating elements, sleeves, and supports; ceramics commonly use molybdenum fixtures and sintered molybdenum boats; almost all oxide ceramic products produced in the electronics industry are fired with molybdenum carriers.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the applications of molybdenum and molybdenum alloys. If you want to learn more about molybdenum or other refractory metals, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as molybdenum, tantalum, rhenium, tungsten, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}