Rhenium Applications | What Is Rhenium Used for?

Rhenium Applications

The previous article, Overview of Rhenium, introduces the discovery history of rhenium (Re), its physical and chemical properties, and magical rhenium effects. In this article, we will take a close look at the rhenium applications. People have tried their best and they only have about 50 tons of rhenium a year. What is rhenium used for?

Rhenium Applications

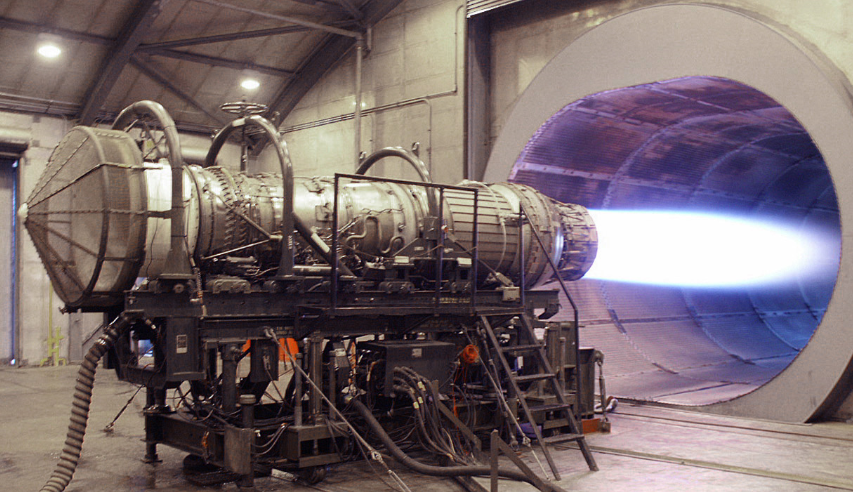

Aerospace Field

Because rhenium and other metals can be made into a series of alloys resistant to high temperature, corrosion, and wear, they can be used to make high-temperature and high-strength parts of supersonic aircraft and missiles and to serve as heat insulation screens.

The rhenium applications in the United States and Western Europe increased greatly, which also led to a sharp increase in the use of rhenium in the world. In recent years, the amount of rhenium in alloys has exceeded its amount in catalysts, and superalloys have become its most important application area.

Rhenium

Petrochemical Catalyst

The platinum-ruthenium catalyst produced by using pure parhelic acid and chloroplatinic acid as key raw materials can be used as a petroleum refining catalyst and an automobile tail purification catalyst. The platinum-rhodium reforming catalyst is used to produce high-octane gasoline and important aromatic hydrocarbon (benzene, toluene, xylene) chemical raw materials.

Heating Elements

To make a thermocouple, the linear relationship between temperature and term electromotive force is required, the temperature measurement is accurate, and the measurement range is wide (0~2485 °C).

The life span of heating elements made of rhenium alloy is 5 ~ 10 times longer than that of tungsten or molybdenum heating elements. The rhenium heating element has the outstanding advantage of working at high temperatures and pressures; it can also produce springs that are both sensitive and non-deformable at high temperatures and are necessary for high-temperature measuring instruments. In addition, as a photosensitive dye that absorbs solar energy, rhenium has broad application prospects on solar cells.

Molybdenum Heating Element

Electronics Industry

Alloys or coating materials composed of rhenium and tungsten, molybdenum, or platinum group metals are widely used in the electronics industry due to their high melting point, high electrical resistance, strong magnetic properties, and good environmental stability.

Rhenium has demonstrated its important uses in vacuum technology and electronic devices or filament in vibrating places, such as X-ray targets, flash, acoustic spectrometers, parts of high vacuum measuring voltage, tungsten-rhenium filaments of aircraft bulbs, heaters for fast start of color TV, etc.

Rhenium can also replace platinum as a switch, electric key, current interrupter, and arc discharge contact components or shielding components in electricians, which has the advantages of reliability and durability.

In recent years, a rhenium matrix composite material has been used as the base material in the ultra-high temperature emitter. The efficiency of thermionic discharge is increased by 20%, the current density is increased, and the performance of thermionic discharge is improved.

Coating and Welding

The high melting point of rhenium and its excellent resistance to corrosion and abrasion is used as a coating, such as the metal wire, slice, or pipe coated with rhenium, which can prevent the corrosion of acid, alkali, seawater, or sulfur compounds, so it is used in the maritime and chemical sectors.

Re-Ni, Re-Mo, or Re-W are used as coatings for instrument components, rocket warheads, and their engines. Re is added to W or Mo alloy to increase its strength, improve its plasticity and welding properties, and can be used as a welding electrode for W or Mo devices.

Other Areas

Medical radioactive rhenium - amino compound phosphate can cure cancer, KReO ₄ preparation of color photographic film can be used as a sensitizer, etc.

Advanced Refractory Metals (ARM) supplies people with high-quality rhenium metals all over the world. Please visit https://www.refractorymetal.org for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}