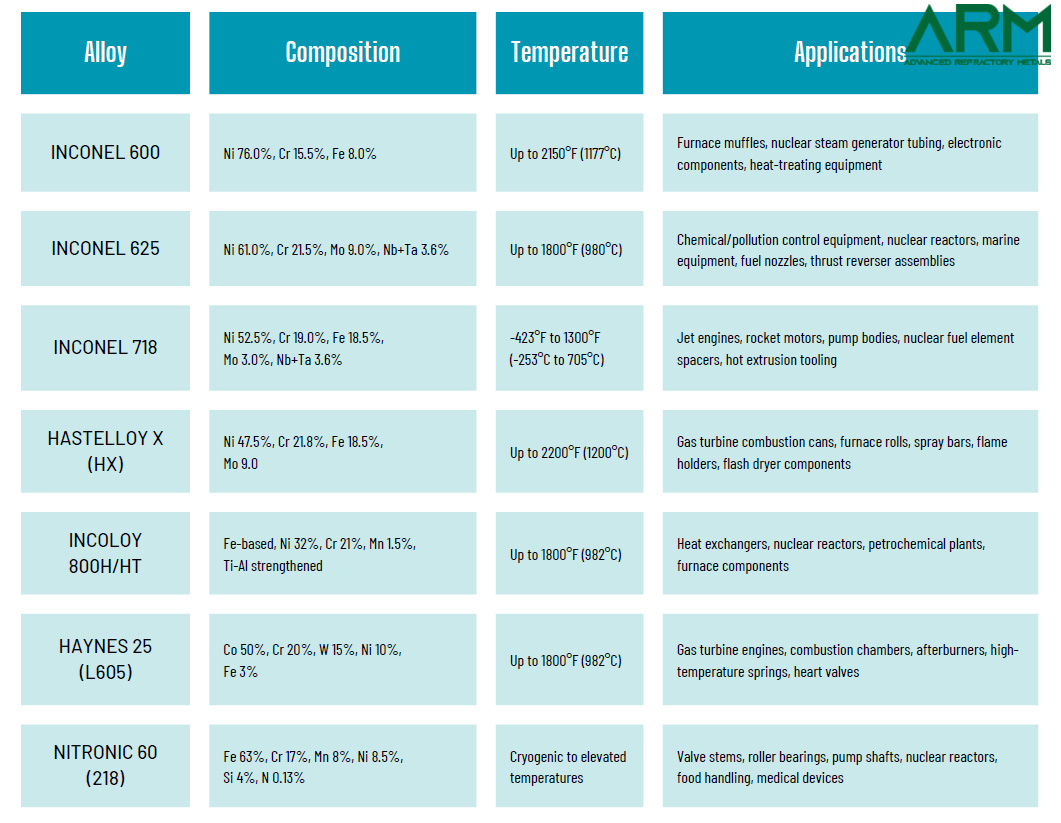

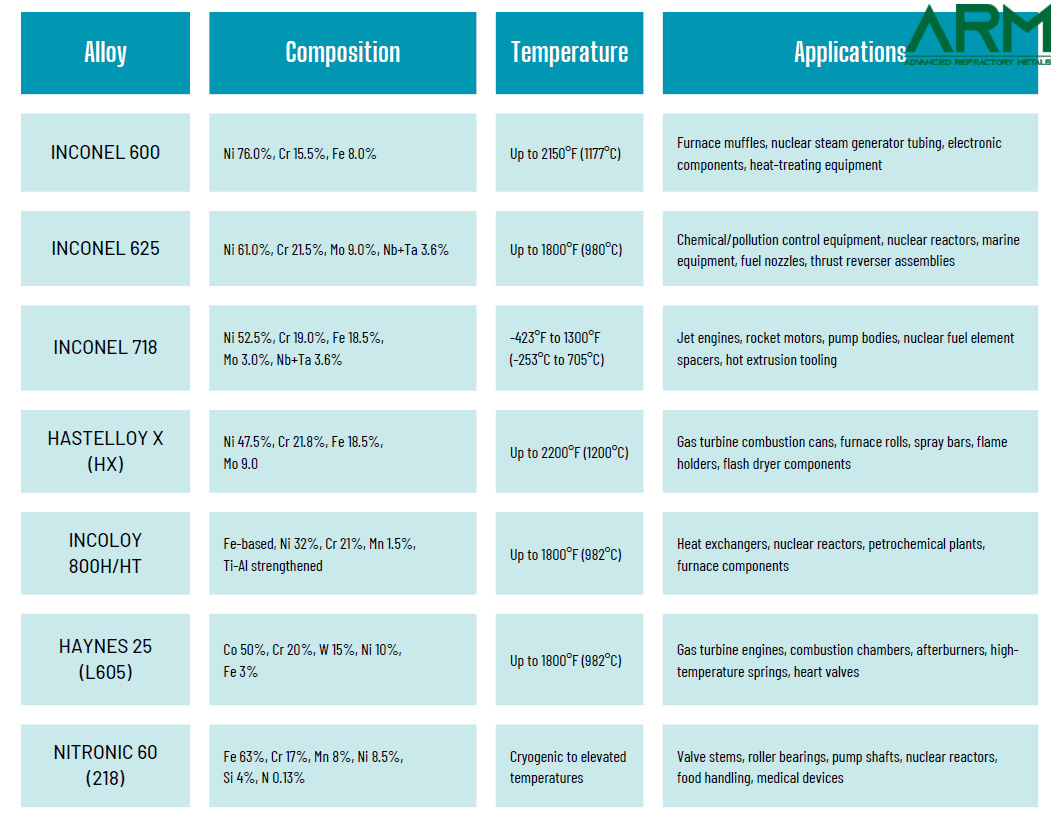

High-Temperature Alloys: Composition, Temperature Range, and Uses

High-temperature alloys are essential in industries where materials are exposed to extreme heat, oxidative environments, and mechanical stress. These alloys are specifically designed to maintain their strength, resistance to corrosion, and structural integrity at elevated temperatures.

Here’s an overview of some of the most commonly used high-temperature alloys, their temperature range, and their applications.

Further reading: A List of Heat-Resistant Materials

1. INCONEL Alloy 600

- Composition: Ni 76.0%, Cr 15.5%, Fe 8.0%

- Temperature Range: Up to 2150°F (1177°C)

INCONEL 600 is a high-nickel, high-chromium alloy that exhibits excellent resistance to both oxidizing and reducing environments. It’s particularly effective in applications where severe corrosion resistance at elevated temperatures is required, including furnace muffles and chemical processing equipment.

Applications: Furnace muffles, nuclear steam generator tubing, electronic components, and heat-treating equipment.

2. INCONEL Alloy 625

- Composition: Ni 61.0%, Cr 21.5%, Mo 9.0%, Nb+Ta 3.6%

- Temperature Range: Up to 1800°F (980°C)

INCONEL 625 is known for its impressive strength, toughness, and resistance to oxidation and corrosion, even at extreme temperatures. The alloy exhibits excellent fatigue strength, making it suitable for components that are subject to repeated stress cycles. It maintains its properties in both cryogenic and elevated temperature environments.

Applications: Chemical and pollution control equipment, nuclear reactors, marine equipment, thrust reverser assemblies, and fuel nozzles.

3. INCONEL Alloy 718

- Composition: Ni 52.5%, Cr 19.0%, Fe 18.5%, Mo 3.0%, Nb+Ta 3.6%

- Temperature Range: From -423°F to 1300°F (-253°C to 705°C)

INCONEL 718 is a precipitation-hardening nickel-chromium alloy that combines high strength with excellent oxidation resistance. This alloy is widely used in industries where parts need to perform in extreme temperatures without losing strength. Its ability to be welded in the fully aged condition adds to its versatility.

Applications: Jet engines, rocket motors, pump bodies, nuclear fuel element spacers, and hot extrusion tooling.

4. HASTELLOY Alloy X (HX)

- Composition: Ni 47.5%, Cr 21.8%, Fe 18.5%, Mo 9.0

- Temperature Range: Up to 2200°F (1200°C)

Hastelloy Alloy X is a nickel-chromium alloy known for its exceptional high-temperature strength and oxidation resistance. This alloy is highly resistant to various corrosive environments, making it ideal for use in gas turbines, heat-treating equipment, and chemical processing. Its ability to withstand prolonged exposure to temperatures between 1200°F and 1600°F for over 16,000 hours makes it a preferred choice for industrial applications that require both durability and performance.

Applications: Gas turbine combustion cans, furnace rolls, spray bars, flame holders, and flash dryer components.

5. INCOLOY Alloy 800H/HT

- Composition: Fe-based, Ni 32%, Cr 21%, Mn 1.5%, Ti-Al strengthened

- Temperature Range: Up to 1800°F (982°C)

INCOLOY 800H/HT is an iron-nickel-chromium alloy that provides excellent resistance to oxidation and carburization, particularly in high-temperature environments. It’s specifically designed to handle creep rupture strength at elevated temperatures, making it highly suitable for the petrochemical and power generation industries.

Applications: Heat exchangers, nuclear reactors, petrochemical plants, and furnace components.

6. HAYNES Alloy 25 (L605)

- Composition: Co 50%, Cr 20%, W 15%, Ni 10%, Fe 3%

- Temperature Range: Up to 1800°F (982°C)

HAYNES Alloy 25, also known as L605, is a cobalt-chromium alloy that is highly resistant to oxidation and carburization at high temperatures. This alloy exhibits excellent strength even at elevated temperatures, making it ideal for components in gas turbines and high-temperature ball-bearing applications. It’s also known for its resistance to galling and corrosion in marine and acid environments.

Applications: Gas turbine engines, combustion chambers, afterburners, high-temperature springs, and heart valves.

7. NITRONIC 60 (Alloy 218)

- Composition: Fe 63%, Cr 17%, Mn 8%, Ni 8.5%, Si 4%, N 0.13%

- Temperature Range: Cryogenic to elevated temperatures

NITRONIC 60 is a high-strength, fully austenitic alloy known for its resistance to galling, wear, and corrosion, especially in chloride environments. This alloy can perform well at both cryogenic and high temperatures, and its oxidation resistance makes it suitable for aerospace, automotive, and chemical industries.

Applications: Valve stems, roller bearings, pump shafts, nuclear reactors, food handling, and medical devices.

Conclusion

High-temperature alloys are vital for industries that rely on materials capable of withstanding extreme heat, mechanical stress, and corrosive environments. Whether it’s the oxidation resistance of INCONEL 625 or the high creep strength of INCOLOY 800H/HT, each alloy offers unique properties tailored to specific needs. For more high-temperature alloys, please check Advanced Refractory Metals (ARM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}