EDM Wire Cutting: A Comprehensive Guide

What Is Wire EDM

Electrical Discharge Machining (EDM) is a non-traditional machining process that removes material using electrical discharges. Wire EDM, or wire electrical discharge machining, employs a thin, electrically charged wire to cut through conductive materials with extreme precision. This process is particularly useful for complex shapes, fine details, and hard materials that are difficult to machine using conventional methods.

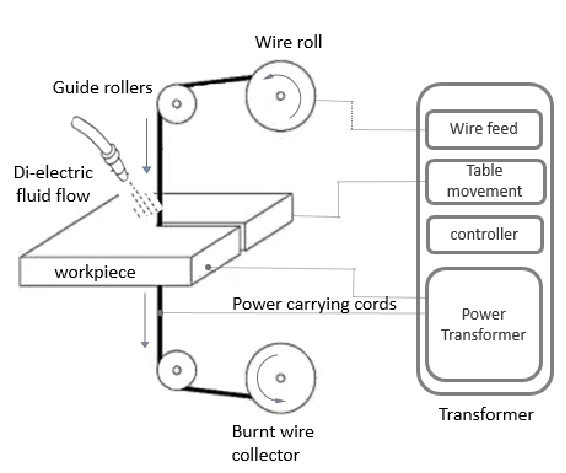

Components of a Wire EDM Machine

A Wire EDM machine consists of several key components that work together to achieve precise cutting:

- Wire Electrode – A thin metal wire, usually made of brass or coated with zinc, that acts as the cutting tool.

- Power Supply – Provides the necessary electrical discharge to erode the material.

- Dielectric Fluid – Deionized water serves as the dielectric medium to flush away debris and cool the workpiece.

- Workpiece Holder – Secures the material in place to ensure stability during cutting.

- Control System – A computerized numerical control (CNC) system directs the movement of the wire for precise cutting.

- Guides and Tensioning System – Keeps the wire properly aligned and under tension for consistent performance.

Further reading: Why Can Molybdenum Wire Cut Metal?

[1]

Materials a Wire EDM Machine Can Cut

Wire EDM is capable of cutting a wide range of conductive materials, including:

- Metals: Stainless steel, titanium, tungsten, aluminum, and copper.

- Superalloys: Inconel, Hastelloy, and other high-performance alloys.

- Hardened Materials: Tool steel, carbide, and hardened aluminum.

- Exotic Materials: Molybdenum, graphite, and certain conductive ceramics.

Since EDM does not involve direct mechanical contact, it can cut through hard materials without introducing stress or deformation.

Further reading: Types and Uses of Molybdenum Wire

EDM Wire Cutting and Conventional EDM

Wire EDM is a specific form of EDM, but it differs from conventional EDM (also known as sinker EDM or ram EDM) in several ways:

|

Feature |

Wire EDM |

Conventional EDM |

|

Electrode Type |

Thin wire |

Shaped electrode |

|

Cutting Method |

Continuous wire cutting |

Single electrode sinking |

|

Best For |

Intricate cuts, profiles |

Cavities, deep holes |

|

Material Removal |

Uses wire to slice through |

Uses shaped tool to erode material |

|

Surface Finish |

High precision, smooth |

Variable, depending on settings |

While both methods use electrical discharge to remove material, wire EDM is best suited for profile cutting, while conventional EDM is preferred for creating deep cavities or molds.

Applications of EDM Wire Cutting Machine

Wire EDM is widely used in various industries due to its precision and versatility. Some key applications include:

- Aerospace Industry: Cutting complex parts from titanium and superalloys used in aircraft and spacecraft components.

- Medical Devices: Manufacturing precision instruments, implants, and surgical tools from biocompatible metals.

- Automotive Industry: Creating transmission components, gears, and fuel injection parts.

- Mold and Die Making: Producing intricate molds, stamping dies, and extrusion dies with high accuracy.

- Electronics Industry: Cutting fine details for circuit boards and micro components.

- Tool and Die Manufacturing: Crafting cutting tools and forming dies for industrial applications.

Conclusion

Wire EDM is a powerful machining process that offers exceptional precision and versatility. Its ability to cut intricate shapes and hard materials without mechanical stress makes it an invaluable tool in industries requiring high accuracy.

Wire EDM remains an essential process for industries requiring intricate, high-precision components. Its ability to work with hard materials and deliver fine details ensures its continued relevance in modern manufacturing. With advancements in technology, Wire EDM continues to be an essential method for producing high-quality components with complex geometries.

Molybdenum cutting wire is an essential tool for cutting hard materials because of its exceptional strength, heat resistance, and wear resistance. Advanced Refractory Metals (ARM) provides high-quality molybdenum cutting wire, ensuring reliability and efficiency in your EDM cutting processes. Visit our homepage for more information on cutting wire and molybdenum wire.

Frequently Asked Questions

Q: What materials cannot be cut using Wire EDM?

A: Non-conductive materials such as plastics, glass, and most ceramics cannot be processed with Wire EDM.

Q: How accurate is Wire EDM?

A: Wire EDM can achieve tolerances as tight as ±0.002 mm (±0.0001 inches), making it one of the most precise machining methods available.

Q: Does Wire EDM require post-processing?

A: In many cases, Wire EDM produces a fine surface finish that requires little to no post-processing. However, some applications may require polishing or additional machining.

Q: Is Wire EDM suitable for mass production?

A: While Wire EDM is excellent for precision machining, it is relatively slow compared to conventional machining methods. It is best suited for prototyping and small to medium production runs rather than high-volume manufacturing.

Reference:

[1] Satynarayana, Kosaraju & Rajkiran, Kumkuma & kumar, Pujari & D, Chakradhar. (2020). A Role of cryogenic in Wire cut EDM process. E3S Web of Conferences. 184. 01067. 10.1051/e3sconf/202018401067.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}