Special Refractories in Steelmaking: Materials and Applications

Refractories are materials that can withstand extremely high temperatures without losing their structural integrity, making them indispensable in industries that operate at elevated temperatures, such as steelmaking. Special refractories, designed to meet the unique demands of steelmaking, play a pivotal role in ensuring that the furnaces, ladles, and other steelmaking equipment operate effectively and consistently.

Understanding Refractories in Steelmaking

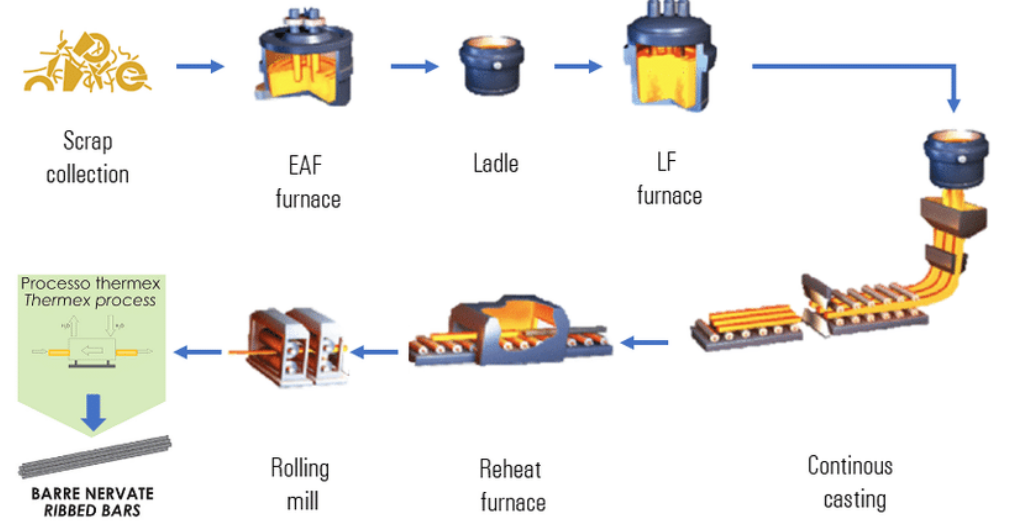

In the context of steelmaking, refractories are used to line equipment exposed to high temperatures, such as blast furnaces, electric arc furnaces (EAF), ladles, and tundishes. They must withstand not only high heat but also chemical and physical stresses that occur during the production process. Steelmaking involves a range of processes, including melting, refining, and casting, each of which generates extreme conditions that require specific types of refractories.

Types of Special Refractories Used in Steelmaking

The variety of conditions in steelmaking necessitates the use of different types of refractories, each with its own set of characteristics. Commonly used special refractories in steel production include:

1. Magnesia-Based Refractories (MgO)

[1]

[1]

Magnesium-based refractories are widely used in steelmaking, particularly in blast furnaces and converters. Magnesia has excellent resistance to high temperatures and is highly resistant to slag and metal corrosion, making it ideal for applications where direct contact with molten metal occurs. Magnesia refractories are commonly used in basic oxygen furnaces (BOF), electric arc furnaces (EAF), and ladle linings.

The high purity magnesia is typically preferred for steelmaking due to its ability to endure extreme conditions without losing structural strength. These refractories are also known for their excellent thermal shock resistance, which is crucial in environments subject to rapid temperature changes.

Further reading: What Are the Special Refractories Widely Used in Modern Industry?

2. Alumina-Based Refractories (Al2O3)

[1]

[1]

Alumina refractories are favored in areas where the temperature may not be as high, but resistance to chemical attack and thermal shock is needed. Alumina is more cost-effective compared to magnesia, though it is less resistant to high temperatures. However, it provides good resistance to slag penetration and can withstand prolonged exposure to oxidizing atmospheres. Alumina-based refractories are commonly used in ladles, tundishes, and in areas with low to medium temperature exposure.

3. Silica-Based Refractories (SiO2)

Silica refractories are often employed in coke ovens, where the conditions of extreme heat and chemical exposure are prevalent. The refractoriness of silica is excellent, particularly when the material is exposed to temperatures up to 1600°C. Silica refractories are resistant to the effects of molten slag and are typically used in the construction of furnace roofs, bottoms, and sidewalls.

4. Zirconia-Based Refractories (ZrO2)

Zirconia refractories are used in high-temperature steelmaking applications, where even magnesia and alumina may fail to meet the required standards. Zirconia refractories exhibit excellent thermal stability and can withstand extremely high temperatures, making them ideal for lining parts of furnaces exposed to the highest heat. Although zirconia refractories are expensive, their use in critical parts of steel production equipment, such as the lining of ladles and the bottoms of furnaces, is justified by their durability.

5. Graphite Refractories

Graphite is known for its exceptional thermal conductivity and resistance to high temperatures. It is often used in combination with other materials like clay or magnesia to form specialized refractories. Graphite refractories are employed in steelmaking processes where high thermal conductivity is needed, such as in certain sections of electric arc furnaces and in the lining of some types of casting molds.

6. Carbon-Based Refractories

Carbon refractories, often used in combination with other materials like silica or alumina, are employed where high thermal conductivity and resistance to wear and oxidation are required. These materials are particularly useful in steelmaking processes where molten metals need to be poured into molds or moved between furnaces.

Applications of Special Refractories in Steelmaking

The application of special refractories is integral to ensuring the smooth and efficient operation of steelmaking processes. Refractories are used across various stages of steel production:

[2]

[2]

- Blast Furnaces

The primary use of refractories in blast furnaces is to line the furnace walls, hearth, and throat. These areas are exposed to extreme temperatures, as well as molten slag and metal. Magnesia-based refractories are commonly used for blast furnace linings due to their ability to resist thermal shock and corrosion from molten metal. - Electric Arc Furnaces (EAF)

EAFs are used for melting scrap steel, and the refractories in these furnaces must withstand not only high temperatures but also intense electrical energy. Magnesia-based refractories are often used in EAF linings, particularly in the furnace roof and sidewalls, to handle the heat generated during the melting process. Additionally, carbon refractories are used for the furnace bottom due to their resistance to slag erosion. - Ladles and Tundishes

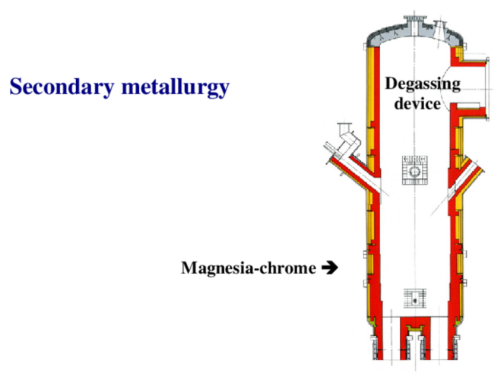

Ladles and tundishes are used to transport and mold steel into billets and other forms. These vessels come into direct contact with molten steel, and special refractories are used to prevent contamination and maintain the integrity of the steel during transfer. Alumina and magnesia-based refractories are typically employed to ensure that molten steel remains uncontaminated and that the equipment can endure the thermal stresses. - Steel Refining and Secondary Steelmaking

Special refractories are used during secondary steelmaking processes like ladle refining, where steel is treated to adjust its composition and remove impurities. Refractories must resist corrosion by molten metal, slag, and oxidizing agents. Magnesia-alumina spinel refractories are often used in these processes for their excellent resistance to slag corrosion. - Continuous Casting

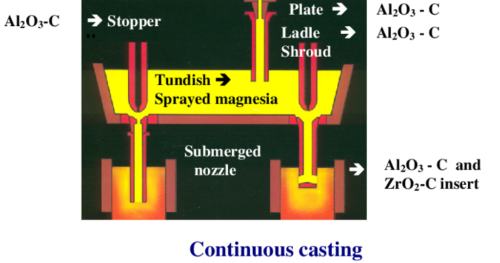

Continuous casting is a process in which molten steel is poured into molds to form billets, slabs, or blooms. Refractories in the continuous casting process must resist high temperatures and thermal shock. Zirconia-based refractories are often used for the nozzles and tundish linings, ensuring that the molten metal is efficiently and safely transferred into molds.

Conclusion

In conclusion, special refractories are essential to modern steelmaking, enabling furnaces, ladles, tundishes, and other equipment to endure the harsh conditions of the production process. The selection of refractory materials—such as magnesia, alumina, zirconia, and others—depends on the unique requirements of each stage in steelmaking and the specific materials being handled. For more refractories and heat resistant materials, please check Advanced Refractory Materials (ARM).

Reference:

[1] Poirier, J.. (2015). A Review: Influence of Refractories on Steel Quality,. Metallurgical Research & Technology. 112. 410. 10.1051/metal/2015028.

[2] Sarda, Kisan & Acernese, Antonio & Nolè, Vittorio & Manfredi, Leonardo & Glielmo, Luigi & Del Vecchio, Carmen. (2021). A Multi-Step Anomaly Detection Strategy Based on Robust Distances for the Steel Industry. IEEE Access. 10.1109/ACCESS.2021.3070659.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}