Zirconium Dioxide Properties & Applications

Zirconium Dioxide Properties & Applications

Zirconium dioxide, also known as zirconia and zirconium oxide, is a non-toxic and odorless white solid. Due to its excellent physical and chemical properties, zirconium dioxide is widely used in industry and our daily life. In this article, we will take a brief look at zirconium dioxide properties and applications.

Zirconium Dioxide

The Properties Of Zirconium Dioxide

Zirconium dioxide is a white heavy amorphous powder, odorless and tasteless, soluble in a mixture of 2 parts sulfuric acid and 1 part water, slightly soluble in hydrochloric acid and nitric acid, slowly soluble in hydrofluoric acid, and almost insoluble in water. It is irritating, with a relative density of 5.85, a melting point of 2680 ℃, and a boiling point of 4300 ℃. Besides, its hardness is only inferior to diamond.

The molecular structure of zirconium dioxide: monoclinic system at low temperature, tetragonal crystal form when it's above 1100 ℃, cubic crystal form when it's above 1900 ℃.

The Applications of Zirconium Dioxide

1. Refractory Materials

Zirconia fiber is a polycrystalline refractory fiber material. Due to the high melting point and other high-temperature characteristics of zirconium dioxide itself, its fiber has a higher service temperature than other refractory fiber varieties such as alumina fiber, mullite fiber, aluminum silicate fiber, and so on.

The zirconium dioxide fiber can be used for a long time under the ultra-high temperature above 1500 ℃, and its maximum service temperature is up to 2200 ℃. Even at 2500 ℃, it can still maintain the complete fiber shape. Besides, the zirconium dioxide fiber is chemically stable at high temperatures, resistant to corrosion and oxidation, non-volatile, and non-polluting. Therefore, its fiber is currently one of the most advanced refractory materials in the world.

2. Gas Turbine

The application of plasma-sprayed zirconium dioxide thermal barrier coatings in aviation and industrial gas turbines has made great progress and has been used in the turbine part of gas turbines within certain limits.

Since this coating can reduce the temperature of air-cooled high-temperature parts by 50 ~ 200 ℃, it can significantly improve the durability of high-temperature parts, or allow the increase of gas temperature or reduce the amount of cooling gas required while maintaining the temperature of high-temperature parts to improve the efficiency of the engine.

3. Ceramic Materials

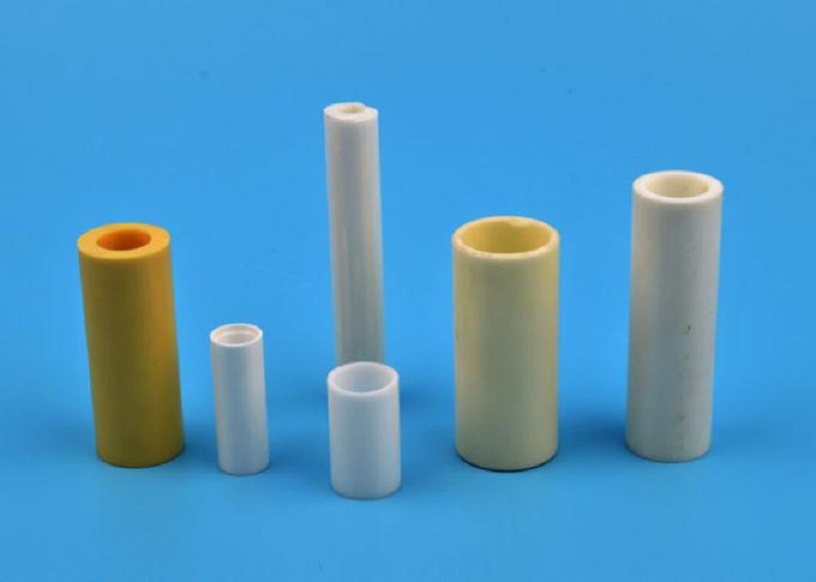

Because of its large refractive index, high melting point, and strong corrosion resistance, zirconia is used as a raw material in the kiln industry. It can also be used to make zirconium bricks and zirconium tubes, etc., for daily ceramics and precious metal smelting.

Zirconia Ceramics

Nanoscale zirconia can also be used as a matrix material for polishing agents, abrasive particles, piezoelectric ceramics, precision ceramics, ceramic glazes, and high-temperature pigments.

4. Other Uses

In addition, zirconia can be used in the manufacture of incandescent gas lampshades, enamel, white glass, refractory crucible, abrasive materials, X-ray photography, etc.

Conclusion

Thank you for reading our article, and we hope it can help you have a better understanding of zirconium dioxide and its properties and applications. If you want to know more about zirconium and other refractory metals, you can pay a visit to Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, ARM is a leading manufacturer & supplier of refractory metals across the whole world. We provide our customers with high-quality refractory metal products like tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}