Types of Tungsten Alloys and Their Uses in the Aerospace

In aerospace engineering, tungsten alloys are essential for various applications requiring high strength, heat resistance, and radiation shielding. Below are the main types of tungsten and tungsten alloys used in aerospace:

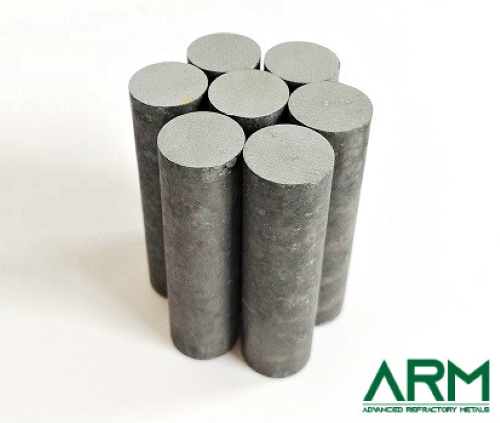

1. Pure Tungsten (W)

Pure tungsten, with a high melting point of 3,422°C (6,192°F), is used in aerospace applications that require extreme heat resistance. However, pure tungsten is often too brittle at room temperature to be useful in many aerospace applications without modification. Its high density (19.25 g/cm³) makes it ideal for radiation shielding, though it is typically combined with other metals to improve its mechanical properties for more demanding applications.

It finds applications in:

- Thermal Protection: Used in heat shields and nozzle extensions for rockets and spacecraft that experience extreme temperatures.

- High-Temperature Components: Employed in components like rocket nozzles and high-performance engine parts that require heat resistance.

2. Tungsten-Copper Alloys (W-Cu)

Tungsten-copper alloys combine the high-temperature resistance of tungsten with the excellent thermal conductivity of copper. These alloys come with the following features:

- High Thermal Conductivity: Copper enhances the material’s ability to dissipate heat.

- Good Electrical Conductivity: The copper content improves the alloy's electrical conductivity, making it useful for certain aerospace electrical components.

- Excellent Strength at Elevated Temperatures: Tungsten’s high melting point is retained, making the alloy suitable for high-stress environments.

They are often used in applications where both high strength and efficient heat dissipation are necessary, such as in aerospace components that require rapid heat removal.

- Heat Sinks and Heat Shields: Used in aerospace systems where rapid heat dissipation is required, such as in spacecraft and rocket engines.

- Electronics: Employed in aerospace electronics where high power dissipation is required, such as in circuit boards or connectors.

3. Tungsten-Nickel-Iron (W-Ni-Fe) Alloys

Tungsten-nickel-iron alloys are some of the most commonly used tungsten alloys in aerospace due to their combination of high density, strength, and toughness. These alloys are more ductile and machinable than pure tungsten, making them easier to fabricate into complex shapes. The addition of nickel and iron also enhances the alloy’s ability to withstand mechanical stress and impact.

- High Density: The alloy’s high density (around 18.5–19.0 g/cm³) is useful for applications where weight is less critical but mass is needed, such as in ballast weights.

- Good Toughness and Strength: Improved toughness compared to pure tungsten, making it more suitable for dynamic aerospace environments.

- Moderate Corrosion Resistance: The nickel and iron content improve resistance to oxidation and corrosion, making these alloys more durable under harsh conditions.

Their applications include:

- Ballast Weights: Used in aerospace applications that require mass for stability, such as in aircraft or spacecraft.

- Counterweights: Found in control surfaces of aircraft or in stabilizing components.

- Armor-Piercing Ammunition: Used in military aerospace applications due to its strength and high density.

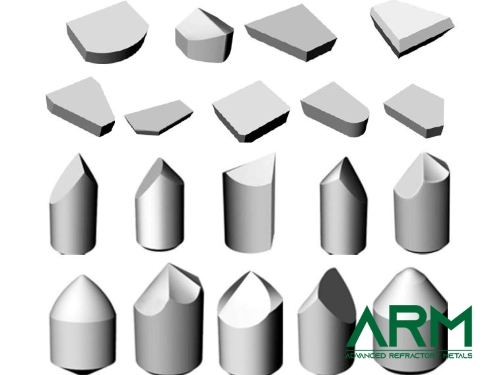

4. Tungsten-Carbide (WC)

Tungsten carbide is an extremely hard and dense material that is primarily used for its wear resistance rather than its thermal properties. It is created by combining tungsten with carbon, resulting in a significantly harder material with diverse benefits.

- Hardness: Tungsten carbide is among the hardest materials, which makes it ideal for applications that involve abrasion or erosion.

- Density: It is also very dense, making it useful for applications where mass is required in a small volume.

- Brittleness: While extremely hard, tungsten carbide is also brittle and can fracture under impact.

Tungsten carbide is commonly used in:

- Cutting Tools and Abrasive Materials: Used in aerospace for cutting tools, drill bits, and other high-wear components.

- Milling and Grinding Tools: Tungsten carbide is used in aerospace manufacturing for parts that undergo high wear during machining processes.

- Turbojet Engine Components: Can be used in parts like blades or nozzles that are exposed to high stress and wear.

5. Tungsten-Rhenium (W-Re) Alloys

Tungsten-rhenium alloys are known for their exceptional performance at high temperatures and their improved ductility compared to pure tungsten. Rhenium is added to tungsten to enhance its high-temperature strength and its ability to maintain mechanical properties under extreme heat.

- Improved Ductility: The addition of rhenium makes these alloys more ductile, allowing for better shaping and machining compared to pure tungsten.

- High-Temperature Strength: These alloys retain their strength even at elevated temperatures, making them ideal for use in high-stress, high-heat environments.

- Resistant to Thermal Fatigue: The rhenium content helps reduce the material's tendency to crack or degrade under repeated thermal cycles.

You can find them useful in:

- Jet Engine Components: Used in gas turbines and nozzles that are exposed to extremely high temperatures in aerospace applications.

- Aerospace Electronics: Rhenium-modified tungsten is used in aerospace electronics that need to operate reliably at high temperatures.

- Thermocouples: Used in high-temperature sensors, as tungsten-rhenium alloys are excellent conductors of heat and electrical signals at elevated temperatures.

6. Tungsten-Molybdenum (W-Mo) Alloys

Tungsten-molybdenum alloys are designed for use in extreme high-temperature applications where both strength and thermal conductivity are necessary. Molybdenum is added to improve the alloy's machinability, and the combination of these metals helps optimize the overall thermal and mechanical performance.

- High-Temperature Stability: These alloys maintain their structural integrity at temperatures well above those that would cause other materials to degrade.

- Improved Machinability: Molybdenum improves the machinability of tungsten alloys, making it easier to manufacture complex parts for aerospace systems.

- Strength: These alloys exhibit high strength and can withstand significant mechanical stress.

Tungsten-Molybdenum alloys find applications in:

- Spacecraft Components: Used in parts of spacecraft that need to withstand high temperatures during launch and re-entry.

- Heat Shields: Employed in heat shields and nozzle extensions, particularly in applications where both thermal stability and strength are required.

Conclusion

Tungsten alloys are indispensable in aerospace engineering due to their high melting points, high density, and strength at elevated temperatures. The choice of which tungsten alloy to use in a particular aerospace application depends on the specific demands of the component, including thermal, mechanical, and radiation shielding properties.

Advanced Refractory Metals (ARM) is a reliable supplier with pure tungsten, tungsten-copper alloys, tungsten-nickel-iron alloys, tungsten-carbide alloys, tungsten-rhenium alloys, and tungsten-molybdenum alloys. Customization and expertise support are also available to meet specific customer needs in industries such as aerospace, defense, and high-performance manufacturing. Send us an inquiry if you are interested.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}