Tungsten Nickel Copper Alloy for New Medical X-ray Protection

Tungsten Nickel Copper Alloy for New Medical X-ray Protection

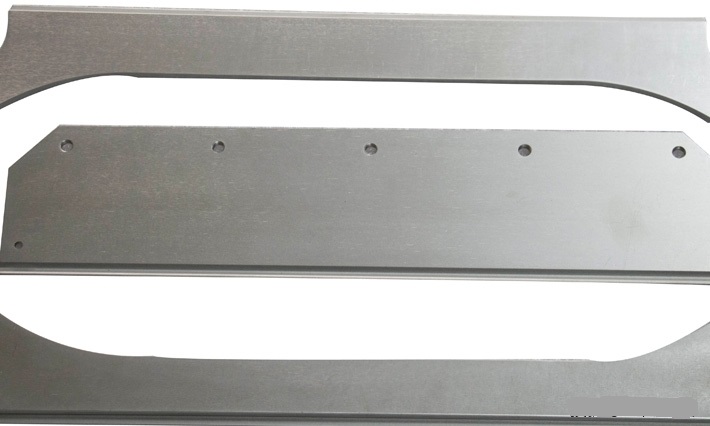

As a new type of medical X-ray protective material, the tungsten-nickel-copper alloy has the characteristics of lead-free, environmental protection, non-magnetic, high density (~18.8g/cm3), strong ability to absorb high energy rays, machinable, weldable, and low thermal expansion coefficient. Therefore, it is widely used in the field of medical radiation shielding and protection-sensitive to the magnetic environment. In this article, let's take a closer look at the tungsten nickel-copper alloy for new medical X-ray protection.

Tungsten Nickel Copper Alloy for New Medical X-ray Protection

Tungsten-nickel-copper alloy refers to an important type of tungsten-based heavy alloy, which is an alloy composed of nickel and copper added to tungsten, and an alloy in which other metal elements are added on this basis. The ratio of nickel to copper added is generally 3:2.

Compared with tungsten-nickel-iron alloys, tungsten-nickel-copper alloys exert their unique anti-interference advantages in areas sensitive to magnetic environments. Compared with the shielding performance of lead, the tungsten-nickel-copper alloy has a strong ability to absorb radiation, and its power is 30-40% higher than that of lead. Compared with lead which is toxic, tungsten alloys have environmental protection characteristics, and the production process of tungsten alloy shielding parts is not harmful to human safety.

In addition, the tungsten-nickel-copper alloy has a high specific gravity, generally 16.5~18.75g/cm. And tungsten nickel-copper alloy has high strength, with a tensile strength of 700~1000MPa. Besides, the tungsten-nickel-copper alloy has a large thermal conductivity (5 times that of die steel) and a small thermal expansion coefficient (only 1/2 to 1/3 of iron or steel).

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the tungsten-nickel-copper alloy for new medical x-ray protection. If you want to learn more about tungsten-nickel-copper alloys, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as niobium, molybdenum, tantalum, rhenium, tungsten, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}