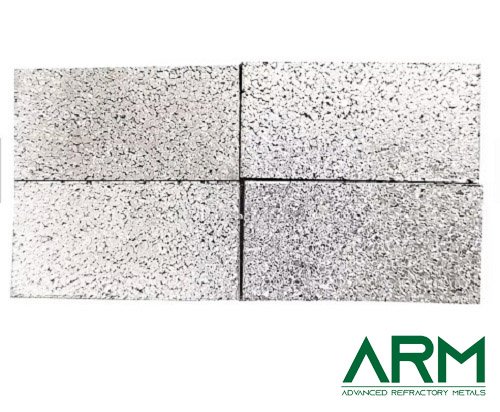

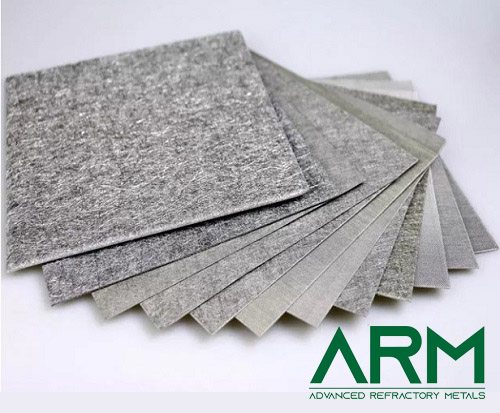

TI1816 Titanium Foam (Ti Foam)

Ultra-light quality: It has the largest specific surface area, the specific gravity is 0.2~0.3, which is 1/4 of water, 1/3 of wood, 1/10 of metal aluminum, 1/30 of iron, and ultra-light quality.

Descriptions of Titanium Foam (Ti Foam)

Ultra-light quality: It has the largest specific surface area, the specific gravity is 0.2~0.3, which is 1/4 of water, 1/3 of wood, 1/10 of metal aluminum, 1/30 of iron, and ultra-light quality.

Sound absorption: The porous structure has a wide frequency of sound absorption.

Electron wave shielding: Shields electron waves of around 90 dB through a relatively thin thickness.

Processability: Can be cut, bent, and simply pasted.

Fire resistance: It maintains a stable shape and is difficult to burn at high temperatures and is resistant to high temperatures.

Recycling: Metal waste materials can be recycled 100%.

Thermal conductivity: Porous materials have strong thermal conductivity.

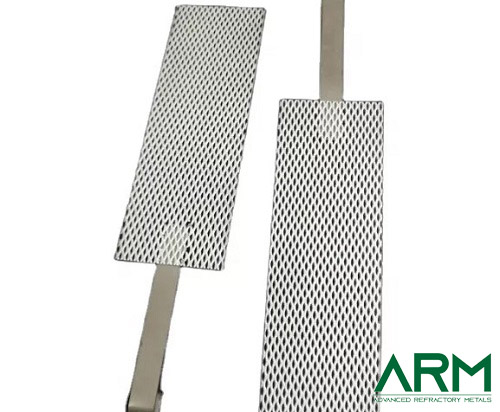

Breathable: a homogeneous three-dimensional network structure with filtering effect and the flow stability of gas and fluid is super strong.

Sound insulation: Through additional processing, a high noise interception can be obtained, and the sound insulation effect is good.

Specifications of Titanium Foam (Ti Foam)

| Specific Heat | 0.125 Cal/g/K @ 25 °C |

|---|---|

| Tensile Strength | 140 MPa |

| Thermal Conductivity | 21.9 W/(m·K) @ 298.2 K |

| Thermal Expansion | 8.6 µm·m-1·K-1 (25 °C) |

| Vickers Hardness | 830–3420 MPa |

| Young's Modulus | 116 GPa |

Applications of Titanium Foam (Ti Foam)

With its unique properties, titanium filter can be widely used in the pharmaceutical industry, water treatment industry, food industry, bioengineering, chemical industry, petrochemical, metallurgical industry, and gas purification. It is a new material with broad development prospects.

Typical uses include:

1. In the infusion of the pharmaceutical industry, small injections, eye drops, decarbonization filtration in the concentration of oral liquids, and security filtration before terminal filtration in the lean distribution.

2. Removal of impurities in the production process of raw materials, decarbonization filtration, and fine filtration of materials.

3. Security filtration of ultrafiltration, RO, EDI systems in the water treatment industry, filtration after ozone sterilization, and ozone aeration.

4. Clarification and filtration of beverages, white sprinkles, beer, vegetable oil, mineral water, soy sauce, and vinegar in food and beverage.

5. Decarbonization filtration and precision filtration of liquid products, liquid raw materials and pharmaceutical intermediates in the chemical industry, ultrafine fine bodies, catalyst recovery, precision filtration after resin adsorption, system heat transfer oil, material removal, and impurity filtration, catalytic gas Purification and so on.

6. Oilfield backflow water filtration, security filtration before reverse osmosis in the desalination field.

7. High-temperature decarbonization and de-whitening filtration in the dye industry.

8. Filtration of steam, compressed air

Packaging of Titanium Foam (Ti Foam)

Our titanium foam is carefully handled to prevent damage during storage and transportation and to preserve the quality of our product in its original condition.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (Optional)

-

Attachment (Optional)

No file chosen

-