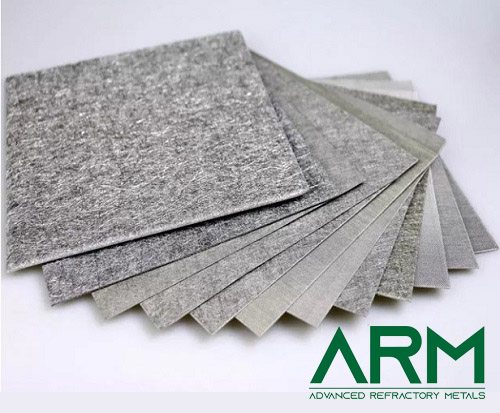

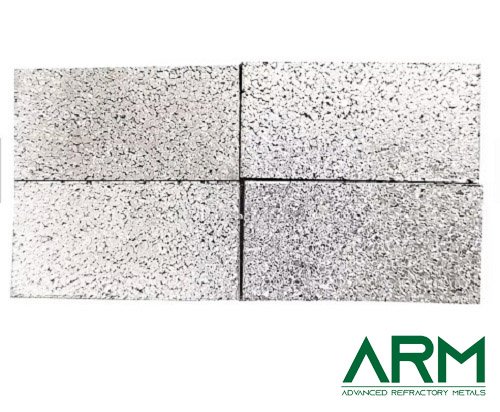

MF2366 Titanium Fiber Felt (Ti)

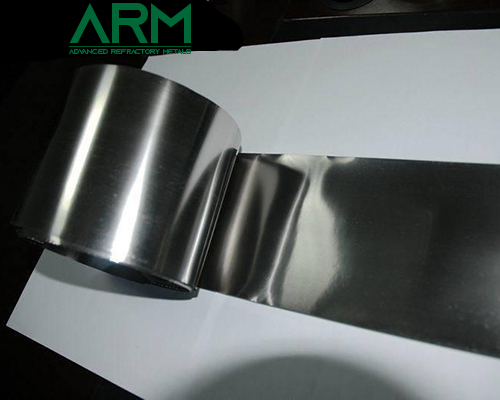

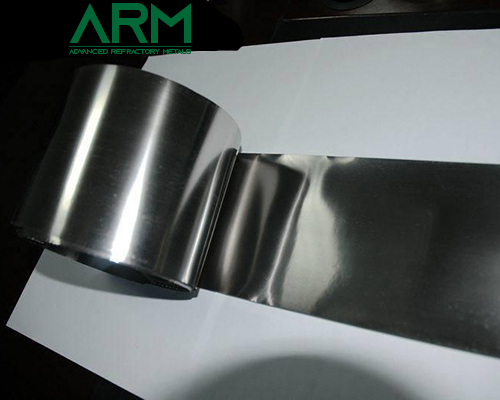

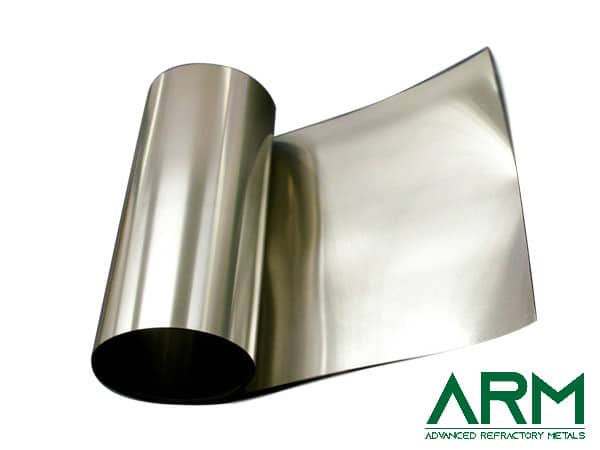

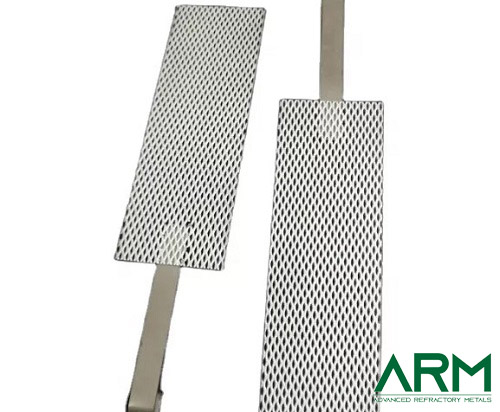

Titanium fiber felt is made by a special laying process and a special ultra-high temperature vacuum sintering process. Compared with titanium powder sintered plate, Ti fiber felt has an excellent three-dimensional network, porous structure, high porosity, large surface area, uniform pore size distribution, special pressure, and corrosion resistance, and can be rolled and processed.

Descriptions of Titanium Fiber Felt

Titanium fiber felt is made by a special laying process and a special ultra-high temperature vacuum sintering process. Compared with titanium powder sintered plate, Ti fiber felt has an excellent three-dimensional network, porous structure, high porosity, large surface area, uniform pore size distribution, special pressure, and corrosion resistance, and can be rolled and processed. Titanium fiber felts are widely used in military, aerospace, civil, medical care, and other industries abroad.

Titanium fiber felts are primarily used in electrolyzer stacks as the flow field or diffuser material, particularly on the oxygen (anode) side.

Specifications of Titanium Fiber Felt

| Catalog No. | MF2366 |

|---|---|

| Symbol | Ti |

| Purity | >99.9% |

| Appearance | Silver grey metallic fiber felt |

| Porosity | 75-78% |

Applications of Titanium Fiber Felt

Titanium Fiber Felt can be used in the following applications:

- Electrolyzer stacks

- Diffusion medium

Packaging of Titanium Fiber Felt

Our Titanium Fiber Felt is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

- Your Name (required)

- Your Email (required)

- Company Name (required)

-

Country (required)

United States

- United States

- Afghanistan

- Aland Islands

- Albania

- Algeria

- American Samoa

- Andorra

- Angola

- Anguilla

- Antarctica

- Antigua and Barbuda

- Argentina

- Armenia

- Aruba

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Bouvet Island

- Brazil

- British Indian Ocean Territory

- British Virgin Islands

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Cape Verde

- Cayman Islands

- Central African Republic

- Chad

- Chile

- China

- Christmas Island

- Cocos (Keeling) Islands

- Colombia

- Comoros

- Congo

- Cook Islands

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Democratic Republic of Congo

- Denmark

- Disputed Territory

- Djibouti

- Dominica

- Dominican Republic

- East Timor

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Eritrea

- Estonia

- Ethiopia

- Falkland Islands

- Faroe Islands

- Federated States of Micronesia

- Fiji

- Finland

- France

- French Guyana

- French Polynesia

- French Southern Territories

- Gabon

- Gambia

- Georgia

- Germany

- Ghana

- Gibraltar

- Greece

- Greenland

- Grenada

- Guadeloupe

- Guam

- Guatemala

- Guinea

- Guinea-Bissau

- Guyana

- Haiti

- Heard Island and Mcdonald Islands

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Iraq-Saudi Arabia Neutral Zone

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jordan

- Kazakhstan

- Kenya

- Kiribati

- Kuwait

- Kyrgyzstan

- Laos

- Latvia

- Lebanon

- Lesotho

- Liberia

- Libya

- Liechtenstein

- Lithuania

- Luxembourg

- Macau

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Martinique

- Mauritania

- Mauritius

- Mayotte

- Mexico

- Moldova

- Monaco

- Mongolia

- Montenegro

- Montserrat

- Morocco

- Mozambique

- Myanmar

- Namibia

- Nauru

- Nepal

- Netherlands Antilles

- Netherlands

- New Caledonia

- New Zealand

- Nicaragua

- Niger

- Nigeria

- Niue

- Norfolk Island

- North Korea

- Northern Mariana Islands

- Norway

- Oman

- Pakistan

- Palau

- Palestinian Territories

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Pitcairn Islands

- Poland

- Portugal

- Puerto Rico

- Qatar

- Reunion

- Romania

- Russia

- Rwanda

- Saint Helena and Dependencies

- Saint Kitts and Nevis

- Saint Lucia

- Saint Pierre and Miquelon

- Saint Vincent and the Grenadines

- Samoa

- San Marino

- Sao Tome and Principe

- Saudi Arabia

- Senegal

- Serbia

- Seychelles

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- Somalia

- South Africa

- South Georgia and South Sandwich Islands

- South Korea

- Spain

- Spratly Islands

- Sri Lanka

- Sudan

- Suriname

- Svalbard and Jan Mayen

- Swaziland

- Sweden

- Switzerland

- Syria

- Taiwan

- Tajikistan

- Tanzania

- Thailand

- Togo

- Tokelau

- Tonga

- Trinidad and Tobago

- Tunisia

- Turkey

- Turkmenistan

- Turks And Caicos Islands

- Tuvalu

- US Virgin Islands

- Uganda

- Ukraine

- United Arab Emirates

- United Kingdom

- United States

- United States Minor Outlying Islands

- Uruguay

- Uzbekistan

- Vanuatu

- Vatican City

- Venezuela

- Vietnam

- Wallis and Futuna

- Western Sahara

- Yemen

- Zambia

- Zimbabwe

- Your Phone (Optional)

-

Metals (Optional)

Tantalum...

-

I would like to join the mailing list to receive updates from Advanced Refractory Metals.

- Notes (required)

-

Attachment (Optional)

No file chosen

-