Rhenium Uses in Aerospace - Shining Pearl of Aerospace Industry

Rhenium Uses in Aerospace

Rhenium has been discovered for almost a century, but it is still an unfamiliar element to most of us. It ranks 75th on the periodic table of chemical elements and is the most recently discovered natural element. In this article, we'll take a look at the rhenium uses in aerospace.

Rhenium Uses in Aerospace

Rhenium is a silver-white metal with little natural content. Rhenium is less abundant in the earth's crust than all rare-earth elements and harder to get than diamonds. It is mostly used in the aerospace industry and is an important strategic precious metal. The world's proven reserves of rhenium are only about 2,500 tonnes, according to the U.S. Geological Survey.

Currently, rhenium and rhenium alloys are widely used in aerospace, electronics, petrochemical, and other fields. One use of rhenium is as a catalyst in the petrochemical industry. Tantalum, a tungsten alloy containing rhenium is considered a high-temperature metal alloy, and the tungsten-rhenium thermocouples can measure the high temperature of 3100 ℃. Rhenium plating (such as on the metal surface of spacecraft) increases the wear resistance of materials, so rhenium has become an important material for aerospace, rockets, and missiles.

In addition, rhenium tungsten alloy is used to make the cathode of an electron tube, the life of which is 100 times longer than that of tungsten. Rhenium is used in manufacturing electric contractors, especially permanent magnet generator contactors for Marine vessels, which is durable.

Rhenium Uses in Aerospace - The Key Metal of an Aero-engine

Rhenium is widely used in jet engines and rocket engines, and about 80% of the world's rhenium is used in aviation engines, which is of great significance in military strategy.

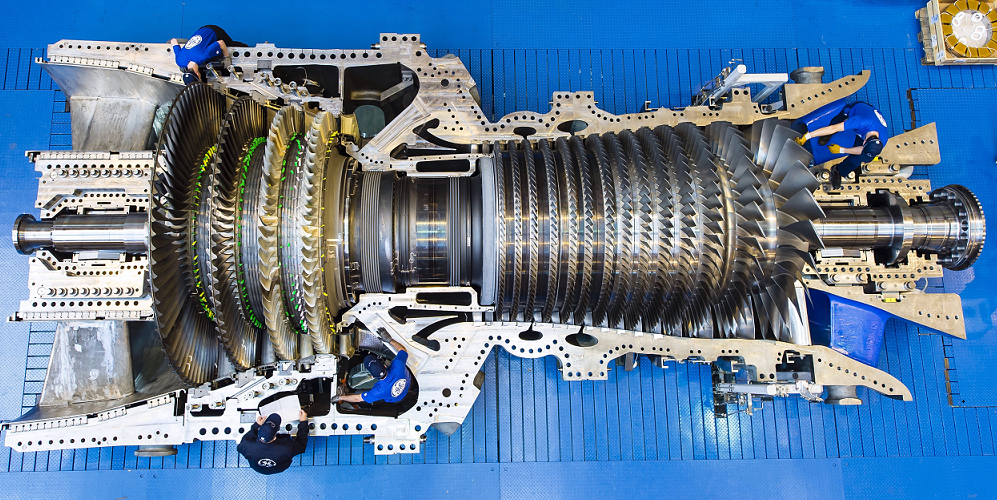

The single crystal blade in the aero-engine is the first key part of the aero-engine, which is located in the parts with the highest temperature, the most complicated stress, and the worst environment, which directly determines the performance of the aero-engine.

At the heart of a 1,000kg engine are 60 single crystal blades. The engine compresses the air and pushes it into the combustion chamber, where it burns violently with the fuel in limited space, producing a violent jet of gas that spins the blades at high speed and produces a stunning burst of power.

Each blade produces as much horsepower as a 2.0-horsepower off-road car. It is reported that a 1000 kilogram level of high-pressure engine speed is close to 40000 revolutions per minute, the tangential velocity is about 450 meters per second, and the temperature is about 1720 ℃. Therefore, the production of single-crystal leaves cannot be separated from the rare metal rhenium.

Rhenium Uses in Aerospace

At present, the annual production of rhenium in the world is 25 ~ 30 tons, and the sales price of rhenium per kilogram on the world market is 1500 ~ 3500 dollars. It is known that with the development of the aviation industry, the annual growth rate of rhenium consumption is 3%. Although rhenium is expensive, it is always in short supply.

With the rise of the aviation industry, rhenium will be used to make high-temperature coatings for rockets and missiles in the future, as well as for instruments and high-temperature components on spacecraft. The strategic value of rhenium will become more prominent in the future with further development in areas such as aero-engines, unmanned aerial vehicles, and high-speed aircraft.

Conclusion

The above is a brief introduction to the rhenium uses in aerospace, and its applications go far beyond that. If you want to know more about the uses of rhenium, you can visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals across the world. We provide our customers with high-quality refractory metals such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}