3 Common Tantalum Products and Their Applications

3 Common Tantalum Products and Their Applications

Tantalum has a series of excellent properties such as high melting point, low vapor pressure, good cold workability, high chemical stability, strong resistance to liquid metal corrosion, and large surface oxide film dielectric constant. Therefore, tantalum has important applications in high-tech fields such as electronics, metallurgy, steel, chemicals, cemented carbide, atomic energy, superconducting technology, automotive electronics, aerospace, medical and health, and scientific research. In this article, let's take a look at 3 common tantalum products and their applications.

Common Tantalum Products and Their Applications

1. Tantalum Powder

Tantalum powder is metallic tantalum in powder form. The dense oxide film formed on the surface of the powder has the properties of a unidirectional conductive valve metal. The anode film made of tantalum powder has stable chemical properties, high resistivity (7.5×1010Ω·cm), high dielectric constant (27.6), and low leakage current. It also has the advantages of a wide operating temperature range (-80~200℃), high reliability, anti-vibration, and long service life.

Tantalum powder can be used to manufacture high-quality electrolytic capacitors (the capacitance is more than 5 times larger than the ordinary capacitance of the same size) and is widely used in military equipment and high-tech fields, such as missiles, space vehicles, televisions, and electronic computers.

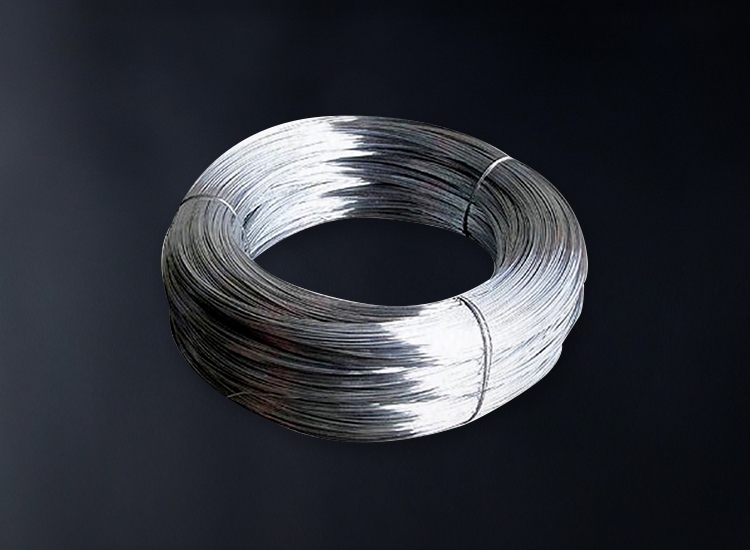

2. Tantalum Wire

Tantalum wire is made of tantalum powder through plastic processing methods such as rolling and drawing. Tantalum wire is used the most in the electronics industry and is mainly used for anode leads of tantalum electrolytic capacitors.

Tantalum wire with high resistance to oxygen brittleness can also be used to make tantalum foil capacitors. It can be used in potassium dichromate and sulfuric acid energizing liquid, under the conditions of high 772 temperature (100°C) and extremely high flash voltage (350V).

In addition, tantalum wire can also be used as a vacuum electron cathode emission source, ion sputtering, and spraying materials, etc.

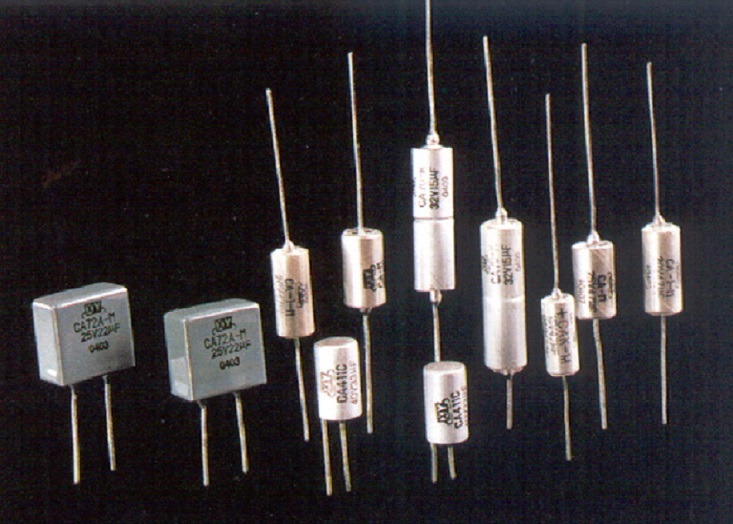

3. Tantalum Capacitor

Tantalum capacitors are processed from the rare metal tantalum. To manufacture tantalum capacitors, tantalum must be ground into fine powders and then sintered together with other media. The current process includes the dry powder molding method and wet powder molding method.

Due to the inherent nature of metal tantalum, tantalum capacitors are stable, do not change with environmental changes, and can achieve large capacitance values. In some aspects, they have some incomparable characteristics of ceramic capacitors. Therefore, tantalum capacitors are widely used in many circuits where ceramic capacitors cannot be used.

Conclusion

Thank you for reading our article and we hope you've enjoyed it. If you want to learn more about common tantalum products and their applications, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals & alloys across the world. It provides customers with high-quality refractory metals & alloys such as tantalum, molybdenum, rhenium, tungsten, titanium, and zirconium at a very competitive price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}