Hafnium Wire in Nuclear Applications

Introduction

Hafnium, a lustrous, silvery-gray metal, is renowned for its exceptional properties, making it a critical material in various high-technology and industrial applications. Among these, its role in nuclear technology stands out due to its unique characteristics and advantages. This article discusses the significance of hafnium wire in nuclear applications, exploring its properties, uses, and latest cases.

Properties of Hafnium

Hafnium (Hf), with an atomic number of 72, possesses several notable properties:

- High Melting Point: Hafnium has a melting point of approximately 2233°C (4051°F), which makes it suitable for high-temperature applications.

- Neutron Absorption: One of the most critical properties of hafnium in nuclear applications is its high neutron absorption cross-section. This means it can effectively absorb neutrons, making it invaluable in controlling nuclear reactions.

- Corrosion Resistance: Hafnium exhibits excellent resistance to corrosion, particularly in aggressive environments, which ensures durability and longevity.

- Mechanical Strength: Hafnium maintains its mechanical strength at high temperatures, crucial for structural components in nuclear reactors.

Related reading: What Hafnium Is Used For?

Applications of Hafnium Wire in Nuclear Technology

Hafnium wire plays a pivotal role in several nuclear technology applications due to its aforementioned properties. The primary applications include:

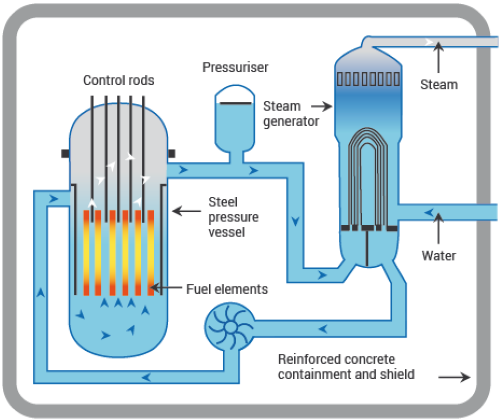

[1]

[1]

- Control Rods in Nuclear Reactors: Control rods are essential for managing the rate of fission in a nuclear reactor. Hafnium's ability to absorb neutrons without becoming radioactive makes it an ideal material for control rods. By adjusting the insertion of hafnium rods into the reactor core, operators can control the reactor's power output and ensure a stable and safe nuclear reaction.

- Shielding Material: In nuclear reactors and other facilities where radiation protection is paramount, hafnium wire can be used as a shielding material. Its high neutron absorption capacity helps protect personnel and sensitive equipment from harmful radiation.

- Nuclear Submarines and Aircraft Carriers: The use of hafnium wire extends to naval nuclear reactors, where its properties are leveraged to enhance the safety and efficiency of reactors in submarines and aircraft carriers. These reactors require materials that can withstand high temperatures and corrosive environments while maintaining structural integrity.

Benefits of Using Hafnium Wire

The utilization of hafnium wire in nuclear applications offers several benefits:

- Safety: Hafnium's high neutron absorption cross-section plays a critical role in enhancing the safety of nuclear reactors by effectively controlling the fission process and preventing the reactor from going critical.

- Longevity: The corrosion resistance of hafnium ensures that components made from hafnium wire can withstand the harsh conditions within a reactor for extended periods, reducing the need for frequent replacements and maintenance.

- Efficiency: The mechanical strength and stability of hafnium at high temperatures contribute to the overall efficiency and reliability of nuclear reactors, ensuring consistent performance under demanding conditions.

Advancements of Hafnium Wire in Nuclear Technology

--Background:

As the nuclear power industry continues to evolve, the need for new materials to manage energy release within the active zone of reactors becomes increasingly critical. One promising material in this domain is hafnium wire. This part discusses the potential roles that hafnium wire could play in addressing the challenges of modern nuclear technology.

--Properties:

Hafnium wire emerges as a viable solution due to its high absorption cross-section for thermal and epithermal neutrons, excellent corrosion resistance, strong mechanical properties, and effective heat conduction.

--Nuclear Applications:

Given its properties, hafnium wire has become an excellent material for regulation rods. These rods are crucial for managing the fission process within a reactor. By using hafnium wire in control rods, reactors can achieve more precise regulation of nuclear reactions, leading to enhanced safety and efficiency.

--Self-Powered Neutron Detectors (SPND):

High-purity hafnium wire can also be used in the emitter material of Compton-type Self-Powered Neutron Detectors (SPND). These detectors are vital for real-time monitoring of neutron flux in a reactor. The application of hafnium wire in SPNDs offers several benefits:

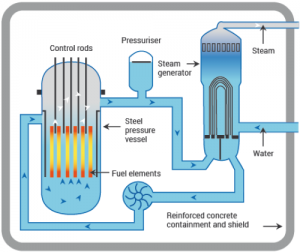

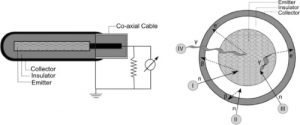

[2]

[2]

- Instant Response: High-purity hafnium ensures that the detectors can quickly respond to changes in neutron flux.

- Improved Safety and Efficiency: The rapid response of SPNDs allows for better control of fuel burn-out times, crisis boiling coordinates, and timing. This capability helps prevent processes that could lead to severe accidents, thereby enhancing reactor safety and efficiency. [3]

Conclusion

Hafnium wire is an indispensable material in the field of nuclear technology, primarily due to its unique combination of high neutron absorption capability, corrosion resistance, and mechanical strength. Its application in control rods, shielding, and naval reactors underscores its importance in maintaining the safety, efficiency, and longevity of nuclear systems.

As the demand for nuclear energy grows and the technology advances, the role of hafnium wire will continue to be critical in meeting the challenges and requirements of modern nuclear applications.

Advanced Refractory Metals (ARM) is a leading global supplier of high-quality hafnium products. We specialize in providing our customers with hafnium wires that boast an impressive 99.95% purity. Our commitment to excellence ensures that our hafnium wires meet the highest industry standards, making them suitable for a wide range of applications. Whether you need hafnium for research, development, or industrial use, ARM is dedicated to delivering top-tier materials to meet your specific requirements.

Reference:

[1] World Nuclear Association (2024, April 20). Nuclear Power Reactors. World Nuclear Association. Retrieved May 27, 2024, from https://world-nuclear.org/information-library/nuclear-fuel-cycle/nuclear-power-reactors/nuclear-power-reactors

[2] V. Verma, L. Barbot, P. Filliatre, C. Hellesen, C. Jammes, S. Jacobsson Svärd, Self powered neutron detectors as in-core detectors for Sodium-cooled Fast Reactors, Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, Volume 860, 2017, Pages 6-12, https://www.sciencedirect.com/science/article/pii/S0168900217304436

[3] Shilyaev, B.A., Ulybkin, A.L., Kovtun, K.V., Rybka, A.V., Kutny, V.E., & Pudov, A.O. (2018). Hafnium in nuclear power industry: the evolution of increasing of the economic indicators and the operation safety of pressurized water nuclear reactors. Voprosy Atomnoj Nauki i Tekhniki, (1-113), 43-49.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}