Effects of Different Preparation Processes on the Properties of Metal foams

Introduction

Metal foams, known for their lightweight structure, high strength-to-weight ratio, and versatile applications, have become vital in industries like aerospace, automotive, and biomedical engineering. The properties of foam metals, such as porosity, mechanical strength, thermal conductivity, and corrosion resistance, are heavily influenced by the preparation process. This article is going to explore the effects of various preparation methods and their implications for different applications.

Understanding Metal foams

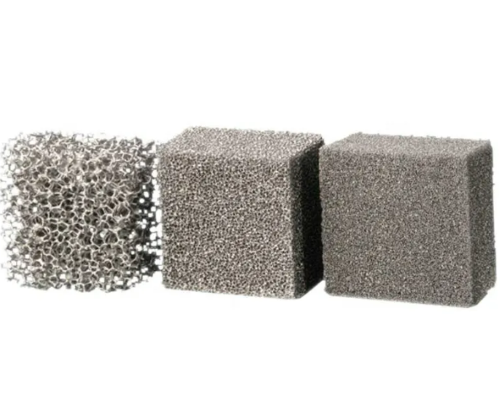

Metal foams are porous metals featuring interconnected or isolated pores, giving them a sponge-like appearance. Their lightweight structure and unique properties stem from their manufacturing processes, making them highly adaptable for different purposes. Choosing the right preparation process is crucial as it directly affects the material’s functionality and performance.

Key Preparation Processes and Their Effects

1. Powder Metallurgy

Powder metallurgy involves compacting metal powders with a foaming agent, followed by sintering to form a porous structure. This method offers precise control over porosity and pore distribution, making it ideal for filters and heat exchangers.

- Effects on Properties:

- Porosity: Uniform and adjustable pore sizes, essential for specific applications like filtration.

- Mechanical Strength: Moderate strength; depends on the quality of sintering.

- Thermal Conductivity: Moderate, influenced by the volume and distribution of pores.

2. Liquid Metal Foaming

In this process, molten metal is foamed by introducing gas or using a foaming agent that generates gas. This results in a material with larger, less uniform pores.

- Effects on Properties:

- Porosity: High porosity with larger, irregular pores.

- Mechanical Strength: Lower compared to other methods due to uneven pore structures, but sufficient for energy-absorbing applications.

- Thermal Conductivity: Reduced due to higher porosity, suitable for insulation or damping.

3. Template-Based Methods

Template-based methods use a pre-formed porous template, such as polymer foam, which is coated with metal and subsequently removed. This approach allows for the replication of complex pore structures.

- Effects on Properties:

- Porosity: Highly customizable, depending on the template.

- Mechanical Strength: Moderate to high, depending on the thickness of the metal coating.

- Corrosion Resistance: Enhanced when using corrosion-resistant metals.

4. Sol-Gel Method

The sol-gel process involves mixing metal precursors into a solution, forming a gel, and then drying it to create a porous structure. This method is often used for nanostructured foam metals.

- Effects on Properties:

- Porosity: Very high, with nanoscale pore sizes.

- Mechanical Strength: Limited due to the fine porosity, but adequate for lightweight and precision applications.

- Thermal and Chemical Stability: Excellent for high-temperature and corrosive environments.

5. Additive Manufacturing (3D Printing)

Additive manufacturing allows the creation of foam metals by selectively depositing or melting metal powders or wires. This technology enables complex and customized designs.

- Effects on Properties:

- Porosity: Fully customizable, allowing for intricate pore geometries.

- Mechanical Strength: High, due to the ability to optimize designs for strength.

- Thermal Conductivity: Tunable based on pore structure.

6. Vapor Deposition

This method involves depositing metal onto a porous substrate using chemical or physical vapor deposition techniques. It is commonly used for coating and creating thin-walled structures.

- Effects on Properties:

- Porosity: Controlled and uniform, with precise structural integrity.

- Mechanical Strength: High for thin films and coatings.

- Corrosion Resistance: Excellent when using noble or corrosion-resistant metals.

7. Electrochemical Deposition

Electrochemical deposition creates foam metal by depositing metal ions onto a conductive scaffold. This method is widely used in producing battery electrodes and catalysts.

- Effects on Properties:

- Porosity: High, with good control over pore size and distribution.

- Mechanical Strength: Moderate, depending on deposition conditions.

- Applications: Primarily for energy storage and chemical catalysis.

Further reading: Metallic Foams: Production, Properties, and Diverse Applications

Comparison of Properties by Process

|

Process |

Porosity |

Strength |

Thermal Conductivity |

Applications |

|

Powder Metallurgy |

Moderate |

Moderate |

Moderate |

Filters, heat exchangers |

|

Liquid Metal Foaming |

High |

Low to Moderate |

Low |

Energy absorption, sound damping |

|

Template-Based |

High |

Moderate to High |

Moderate |

Biomedical scaffolds, filters |

|

Sol-Gel |

Very High |

Low |

Low |

Sensors, catalysis |

|

Additive Manufacturing |

Customizable |

High |

Customizable |

Aerospace, medical applications |

|

Vapor Deposition |

Low to Moderate |

High |

High |

Catalysts, electrodes |

|

Electrochemical Deposition |

High |

Moderate |

Moderate |

Batteries, fuel cells |

Challenges and Considerations

Despite their advantages, metal foams face challenges:

1. Cost: Advanced processes like additive manufacturing and vapor deposition can be expensive.

2. Fragility: Methods like sol-gel may produce structures with limited mechanical strength.

3. Customization Limits: Some processes, such as liquid metal foaming, lack precise control over pore size.

Innovations and Future Outlook

Emerging technologies like hybrid manufacturing methods and nanostructuring are enhancing the properties of foam metals. For instance, combining additive manufacturing with template-based methods provides precision and scalability. Research into advanced coatings and alloy compositions also promises improved corrosion resistance and mechanical performance.

Conclusion

The properties of metal foams are intrinsically linked to their preparation methods. Understanding these effects helps tailor the materials for specific applications, from lightweight aerospace components to durable industrial filters. With ongoing innovations, foam metals are set to play a pivotal role in advancing technology and sustainability. For more metal products, please check Advanced Refractory Metals (ARM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}