Classification & Uses of Tantalum Wire

Classification & Uses of Tantalum Wire

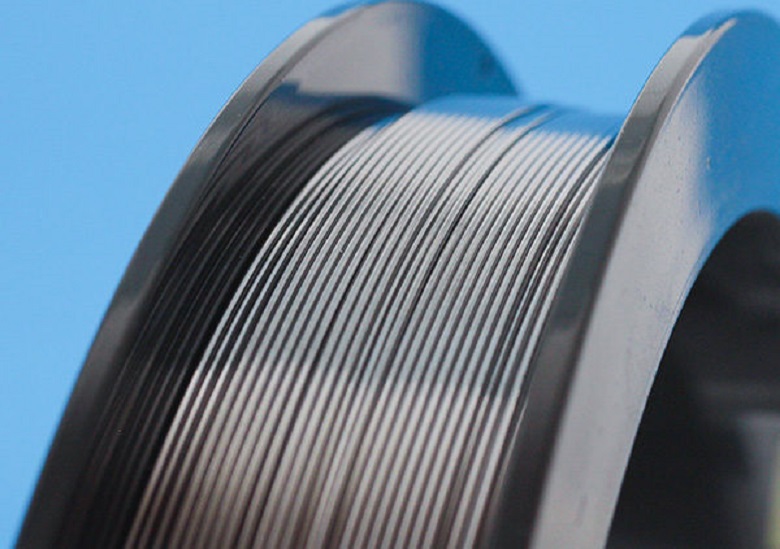

Tantalum is the third most refractory metal after tungsten and rhenium, with a melting point of 2980 ° C. In addition, tantalum also has a series of excellent properties such as low vapor pressure, good cold workability, high chemical stability, strong resistance to corrosion of liquid metals, and a large dielectric constant of the surface oxide film. Therefore, tantalum and tantalum wire have important applications in high-tech fields such as solid alloys, atomic energy, superconducting technology, automotive electronics, aerospace, medical and health, and scientific research. In this article, we will take a look at the classification and uses of tantalum wire.

Classification & Uses of Tantalum Wire

The Classification of Tantalum Wire

Tantalum wire can be classified according to its chemical purity, performance, use, and status.

1. According to its purity, tantalum wire can be divided into 3 categories: metallurgical tantalum wire, purity 99.0% Ta; high purity tantalum wire, purity 99.0% -99.9% Ta; ultra-high purity tantalum wire, purity 99.9% -99.99% Ta.

2. According to performance, tantalum wire can be divided into 4 categories: chemical corrosion-resistant tantalum wire; high temperature resistant high-strength tantalum wire; oxygen-resistant brittle tantalum wire; capacitor tantalum wire.

3. The tantalum wire of the capacitor is divided into 3 categories according to its uses: tantalum wire for the lead of solid tantalum electrolytic capacitors; tantalum wire for liquid tantalum electrolytic capacitor leads; tantalum wire for capacitors with reliability indicators.

4. According to the status, the capacitor tantalum wire can be divided into three categories: soft state, tensile strength σb = 300 ~ 600MPa; semi-hard state, tensile strength σb = 600 ~ 1000MPa; hard state, tensile strength σb> 1000MPa.

The Uses of Tantalum Wire

1. Tantalum wire is the most widely used in the electronics industry and is mainly used for the anode lead of tantalum electrolytic capacitors. Tantalum capacitors are the best capacitors, and about 65% of the world's tantalum is used in this field.

2. Tantalum wire can be used to compensate for muscle tissue and to suture nerves and tendons.

3. Tantalum wire can be used for heating parts of a vacuum high-temperature furnace.

4. High anti-oxidation brittle tantalum wire can also be used to make tantalum foil capacitors. It can work in potassium dichromate at high temperatures (100 ℃) and extremely high flash voltage (350V).

5. In addition, tantalum wire can also be used as a vacuum electron cathode emission source, ion sputtering, and spray coating materials.

Conclusion

Thank you for reading our article, and we hope it can help you have a better understanding of the classification & uses of tantalum wire. If you want to know more about tantalum wire and other refractory metals, you can visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, ARM is one of the leading manufacturers & suppliers of refractory metals across the world and we guarantee all the refractory metal products provided by ARM are high in quality and affordable in price.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}