Beryllium X-Ray Windows: Case Studies

What Are Beryllium X-Ray Windows?

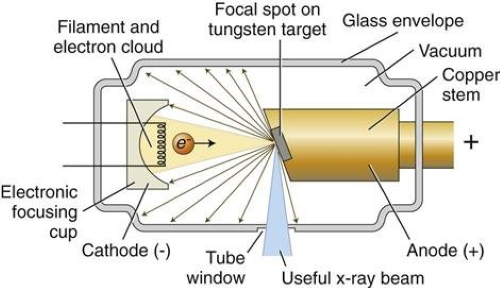

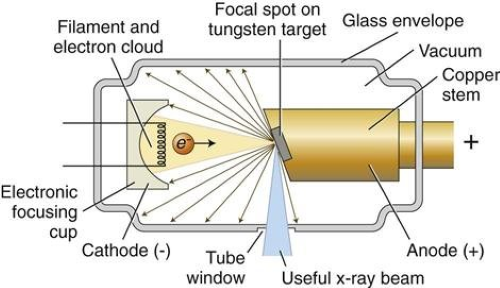

Beryllium X-ray windows are thin, transparent barriers placed in X-ray tubes to allow X-rays to pass through while preventing the passage of unwanted particles or gases. Beryllium is chosen for its unique combination of low atomic number, high transparency to X-rays, and exceptional mechanical properties.

- High X-Ray Transparency: Beryllium’s low atomic number (Z=4) allows X-rays to pass through with minimal attenuation. This makes it ideal for applications requiring the precise transmission of X-ray beams without significant loss of intensity.

- Lightweight: Beryllium’s low density reduces the overall weight of X-ray tubes, which is beneficial for portable X-ray devices or systems where weight is a concern.

- Thermal Conductivity: Beryllium possesses superior thermal conductivity, helping to dissipate the heat generated during the X-ray process. This prevents overheating and extends the lifespan of the X-ray tube.

- Chemical Resistance: Beryllium is resistant to corrosion, ensuring that the windows remain effective and stable even in harsh chemical environments or under extreme conditions.

[1]

[1]

Further reading: 6 Common Uses of Beryllium

Uses of Beryllium X-Ray Windows

Beryllium X-ray windows are widely used in various fields, including:

- Medical Imaging: Beryllium windows are critical components in X-ray machines, including CT scanners and fluoroscopes. Their ability to transmit X-rays with minimal distortion enhances image clarity and diagnostic accuracy.

- Industrial Inspection: In industrial radiography, beryllium windows are used in X-ray systems for inspecting materials such as metals, composites, and welds. The high transparency ensures that the X-ray beam penetrates the materials effectively for detailed internal examination.

- Scientific Research: Beryllium windows are also used in synchrotron radiation facilities and other high-energy physics experiments. In these settings, the need for high precision and low X-ray absorption is paramount, making beryllium an optimal choice.

Case Study: Beryllium X-Ray Windows for X-Ray Analysis

--Background:

A client in the Netherlands approached Advanced Refractory Metals (ARM) to inquire about beryllium (Be) windows for use in X-ray analysis applications. The client required 5 round beryllium windows, each with a thickness of 12.5 microns and a diameter of 10 mm, tailored to meet the precision demands of their X-ray systems.

--Solution:

ARM provided a customized quote for 5 beryllium windows with the specified dimension. These windows were chosen to ensure optimal performance in X-ray analysis while preserving the vacuum integrity of the system. We also included shipping to the Netherlands, ensuring the windows were carefully packaged and delivered on time.

--Result:

The customer successfully received the beryllium windows, meeting all technical specifications. The upgraded X-ray systems, now equipped with high-quality beryllium windows, performed optimally, supporting the client’s analysis applications. The smooth process, including international shipping, ensured there were no delays, enabling the client to continue their work seamlessly.

Caring for Beryllium Windows Used in X-Ray Tubes

Beryllium windows in X-ray tubes are fragile and toxic if mishandled. These high-purity windows maintain vacuum integrity, but care is required.

- Avoid direct contact with the window, as beryllium is toxic. Always use protective equipment.

- The window is prone to damage from impact. Also, exposure to polar solvents (water, alcohol, acids) can degrade the material and compromise the vacuum.

- If cleaning is needed, use a cotton swab with acetone and immediately dry the window with soft air or cloth.

- Ensure the window is at least 127 microns thick for helium applications, as beryllium transmits helium well.

- To prevent damage from pressure cycling, use a secondary chamber for sub-atmospheric operation.

Conclusion

Beryllium windows are an essential component in X-ray tubes. Their high X-ray transparency, mechanical strength, and durability make them critical for efficient and reliable X-ray systems. Proper care and handling of beryllium windows are necessary to ensure both safety and longevity.

Advanced Refractory Metals (ARM), based in Lake Forest, California, is a leading supplier of high-quality refractory metals, including Tungsten, Molybdenum, Tantalum, Rhenium, Titanium, and Zirconium. Since 1994, we have provided advanced products to industries such as aerospace, semiconductor, and chemical processing.

ARM specializes in custom solutions to meet specific customer needs, including beryllium windows for X-ray analysis. Our in-depth metallurgical expertise ensures that our beryllium windows are manufactured to the highest standards, offering reliable performance and durability for demanding applications.

Reference:

[1] Roque, Rita. (2018). X-ray imaging using 100 μm thick Gas Electron Multipliers operating in Kr-CO2 mixtures. 10.13140/RG.2.2.16794.49600.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}