6 Major Uses of Tungsten-Silver Alloy

Introduction

Tungsten-silver (W-Ag) alloys blend the high strength and melting point of tungsten with the excellent electrical and thermal conductivity of silver. This synergy finds use in a wide range of industries. This article will brief six major applications of W-Ag alloys, highlighting their critical roles in various fields.

Importance of Tungsten-Silver Alloy

W-Ag alloys stand out due to their exceptional physical and chemical properties. Tungsten has the highest melting point of all metals at 3,422°C (6,192°F), and silver offers the highest electrical and thermal conductivity among metals. When combined, W-Ag alloys leverage these attributes to provide superior performance in demanding environments.

For instance, the use of W-Ag alloys in contacts and switches significantly reduces wear and erosion, extending the lifespan of components. In a study conducted by the IEEE, the integration of W-Ag alloys in high-voltage switches demonstrated a 25% increase in lifespan and a 15% reduction in maintenance costs compared to traditional copper-based contacts. Related reading: 3 Most Common Types Of Tungsten Alloys Used Today

Six Major Uses of Tungsten-Silver Alloy

1. Electrical Contacts and Switches

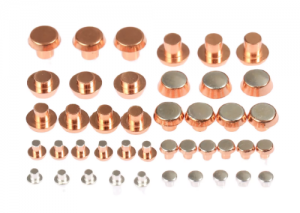

Tungsten-silver alloys are widely used in electrical contacts and switches. W-Ag alloys offer a good balance of high conductivity and resistance to wear and arc erosion. Silver provides excellent electrical conductivity, while tungsten adds hardness and a high melting point, making the material durable under high current loads and frequent switching. In industries like telecommunications and power generation, W-Ag electrical contacts ensure consistent performance, reducing the need for frequent replacements and maintenance, leading to lower costs and better system reliability.

2. Electrodes for Electrical Discharge Machining (EDM) and Welding

Tungsten-silver alloys are also used to make electrodes for Electrical Discharge Machining (EDM) and welding. EDM is a process where material is removed from a workpiece by electrical discharges (sparks). The electrodes used in EDM must withstand high temperatures and maintain their shape and integrity over prolonged use. W-Ag electrodes are highly valued because of their excellent thermal conductivity, high melting point, and resistance to erosion. They provide precise machining capabilities, making it possible to create complex and high-precision parts in industries like aerospace, automotive, and tool manufacturing. In welding, W-Ag electrodes offer stable arc characteristics and long service life, which are essential for high-quality welds in demanding environments.

3. Heat Sinks and Thermal Management Systems

W-Ag alloys are widely used in heat sinks and thermal management systems because of their superior thermal conductivity. Silver helps to rapidly dissipate heat, while tungsten ensures structural integrity at high temperatures. Heat sinks made from W-Ag alloys are found in high-power electronic devices such as transistors, laser diodes, and microwave devices. These heat sinks effectively dissipate heat away from sensitive components, preventing overheating and failure. This is particularly important in industries like telecommunications, computing, and consumer electronics.

4. Aerospace Components

The aerospace industry needs materials that can withstand extreme conditions, and W-Ag alloys meet these requirements. Their high melting point and strength ensure they perform reliably in critical applications such as rocket nozzles, propulsion systems, and structural parts of spacecraft. W-Ag alloys maintain their properties at high temperatures, making them suitable for use in turbine blades and other engine components. These materials help improve the efficiency and safety of aerospace systems, playing a vital role in both commercial and defense aviation.

5. Radiation Shielding

Tungsten's high density makes it effective for radiation shielding. When combined with silver, W-Ag alloys provide enhanced protection against X-rays and gamma rays. This makes them valuable in medical, industrial, and nuclear applications. In medical settings, W-Ag alloys are used in protective shields for diagnostic imaging equipment and radiation therapy devices. They help safeguard both patients and healthcare workers from harmful radiation exposure. In industrial and nuclear facilities, these alloys are used in shielding containers and barriers, ensuring the safe handling and storage of radioactive materials.

6. Medical Devices and Implants

The biocompatibility, strength, and corrosion resistance of tungsten-silver alloys make them suitable for various medical applications. In surgical instruments, W-Ag alloys offer precision, durability, and resistance to sterilization processes. Their high strength ensures they remain sharp and effective during repeated use. W-Ag alloys are also used in medical implants, such as pacemaker electrodes and neurostimulation devices. Their biocompatibility ensures they do not cause adverse reactions in the body, while their conductivity and stability enhance the performance of these critical devices.

Conclusion

| Application | Key Properties | Industries |

| Electrical Contacts and Switches | High conductivity, wear and arc erosion resistance | Telecommunications, power generation |

| Electrodes for EDM and Welding | Thermal conductivity, high melting point, erosion resistance | Aerospace, automotive, tool manufacturing |

| Heat Sinks and Thermal Management | Superior thermal conductivity, structural integrity | Telecommunications, computing, consumer electronics |

| Aerospace Components | High melting point, strength at high temperatures | Aerospace (commercial and defense) |

| Radiation Shielding | High density, radiation protection | Medical, industrial, nuclear |

| Medical Devices and Implants | Biocompatibility, strength, corrosion resistance | Medical devices and technology |

The unique properties of tungsten-silver alloys make them indispensable in multiple industries, ranging from electrical contacts, machining electrodes, and electronics, to radiation shielding. For more tungsten alloys, please check Advanced Refractory Metals (ARM).

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}