Why Is Titanium Price So High?!

Why Is Titanium Price So High?!

If steel is a metal that has a profound impact on the world in the middle of the 19th century, then the next metal that will change the world will be titanium. Titanium is known as "the steel of the future." Thanks to the excellent properties of titanium, it is widely used in aviation, aerospace, chemical industry, electricity, medical, construction, sports goods, and other fields. But at present, the price of titanium products in the market is very high, which discourages many consumers. So why is titanium price so high?!

Why Is Titanium Price So High

The following are the reasons why titanium and titanium products are so expensive:

1. Difficult to Exploit and Use

The ilmenite sand ore is extremely scattered and has a low concentration of resources. After years of mining, large-scale and high-quality resources have been exhausted.

In addition, the current exploitation of titanium resources is mostly private, and it is difficult to form large-scale development and utilization. Some coastal titanium ore deposits have radioactive elements, and the environmental protection pressure is high.

2. Lack of Titanium Production Capacity

Titanium is mainly used in aerospace, construction, marine, nuclear and power fields. In addition, titanium is widely used in chemical, sports, electronics, automotive, and medical fields. Currently, there are only a few industrialized countries in the world that can produce titanium.

3. Difficult to Process

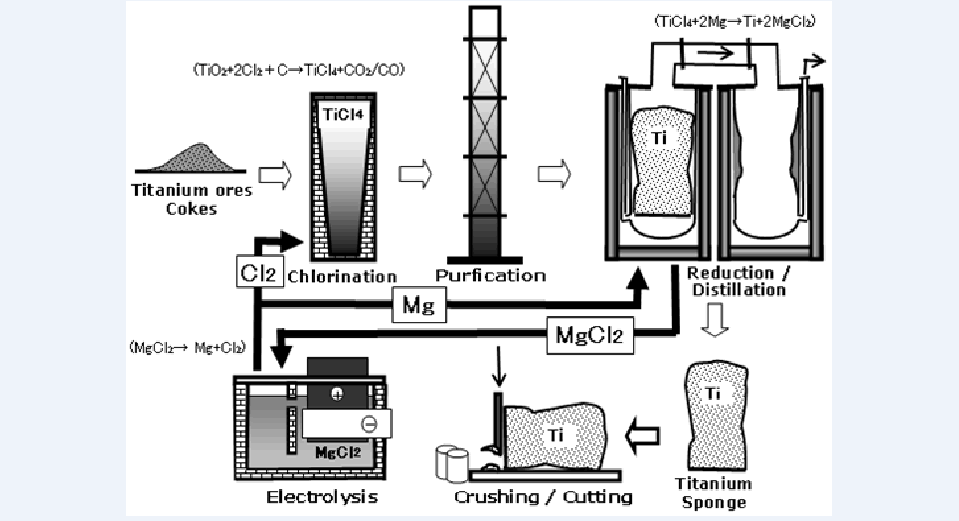

Sponge titanium is the raw material of titanium material, titanium powder, and other titanium components. It must be remelted with an electric furnace to become new structural material - titanium ingots.

From sponge titanium to titanium ingots to titanium plates requires dozens of procedures, most of which need to be smelted more than twice, not only to control the melting rate, voltage, and current but also the composition.

From titanium ingots to slabs, multiple forgings are required. From slab to plate, it has to go through multiple processes such as heating, cold rolling, and hot rolling, which are numerous and complicated.

Why Is Titanium Price So High?!

Pure titanium is very soft and is generally not suitable for use as a titanium product, so other elements need to be added to improve metal properties. For example, titanium-64, which is commonly used in the aviation industry, needs to be doped with many other elements to improve metal properties.

However, at high temperatures, titanium reacts strongly with elements such as halogens, oxygen, sulfur, carbon, and nitrogen, which can contaminate titanium. Therefore, titanium needs to be smelted in a vacuum or inert atmosphere.

Titanium is difficult to machine. If the speed is low, the titanium cannot be cut at all. If the speed is too high and too much heat is generated, titanium will oxidize. Therefore, ordinary machining centers cannot process titanium alloy products at all.

Titanium is a lively metal. The reason why it is resistant to corrosion is that the surface passivation layer is much stronger than aluminum. In addition, titanium has extremely poor thermal conductivity, which makes it more difficult to weld with other materials.

4. Strong Demand for Titanium and Titanium Products

As a new metal material, titanium is in great demand. The consumption of titanium is directly proportional to the comprehensive national strength and development level of a country. As the comprehensive national strength of various countries in the world continues to increase, the consumption of titanium has also increased rapidly.

Conclusion

In summary, there are many factors that affect titanium prices, such as the strong demand for titanium and titanium products and the difficulty to process titanium. However, with the progress of titanium production and processing technology, the cost of titanium products will be reduced accordingly. It is believed that shortly, titanium household products will become more and more popular, adding color to the happiness and healthy life of more people.

Thank you for reading our article and we hope you've enjoyed it. If you want to know more about titanium prices and the price of other refractory metals, you can visit Advanced Refractory Metals (ARM) for more information. Headquartered in Lake Forest, California, ARM is a leading manufacturer & supplier of refractory metal products such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}