Refractory Metals Properties | What Makes Refractory Metals So Unique?

Refractory Metals Properties

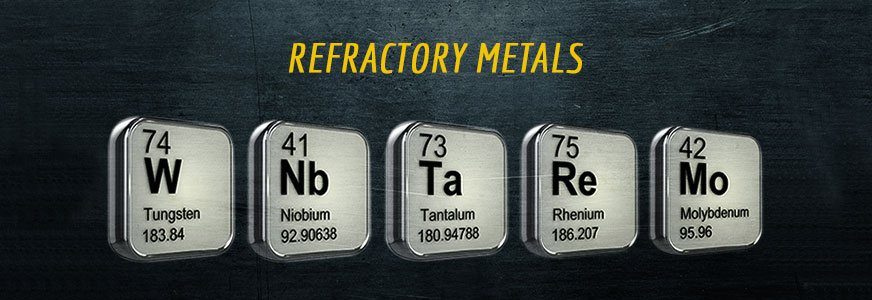

Refractory metals mainly include tungsten, tantalum, molybdenum, niobium, hafnium, chromium, vanadium, zirconium, and titanium. Actually, the melting point of rhenium also is extremely high, but its reserves are too rare, most used in high-temperature alloy parts of the jet engine. Among them, the most common refractory metals are tungsten, tantalum, molybdenum, and niobium. In this article, we will take a look at these four commonly-used refractory metals properties.

Refractory Metals Properties

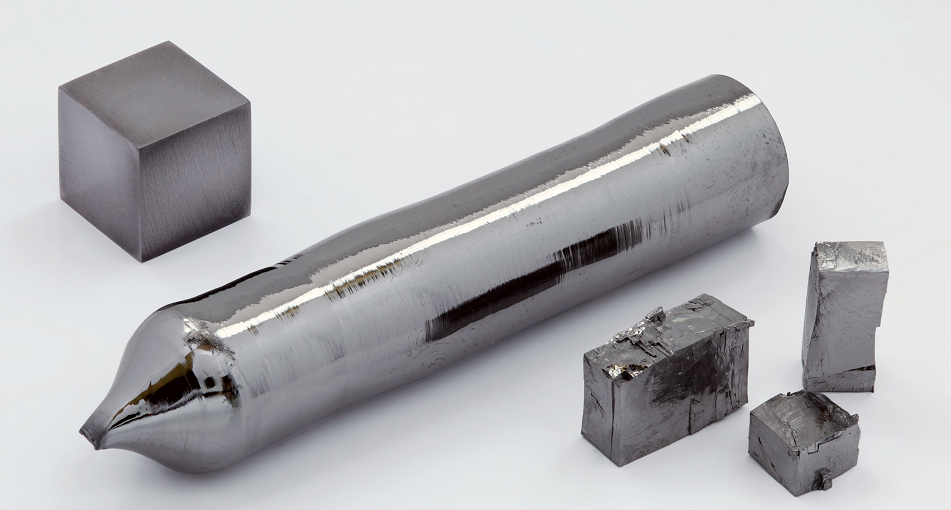

Refractory Metals Properties - 1. Tungsten

It has the highest melting point among commonly used refractory metals, reaching 3410±20℃. It is silver-white and looks like steel. Not only is tungsten hard, but it is also chemically stable. Most acids and bases have only a slight effect on tungsten. Hydrogen, water, or dilute acids have no effect on tungsten. Corrosion occurs only in hot aqua regia and a 1: 1 mixture of hydrofluoric acid and nitric acid.

Tungsten

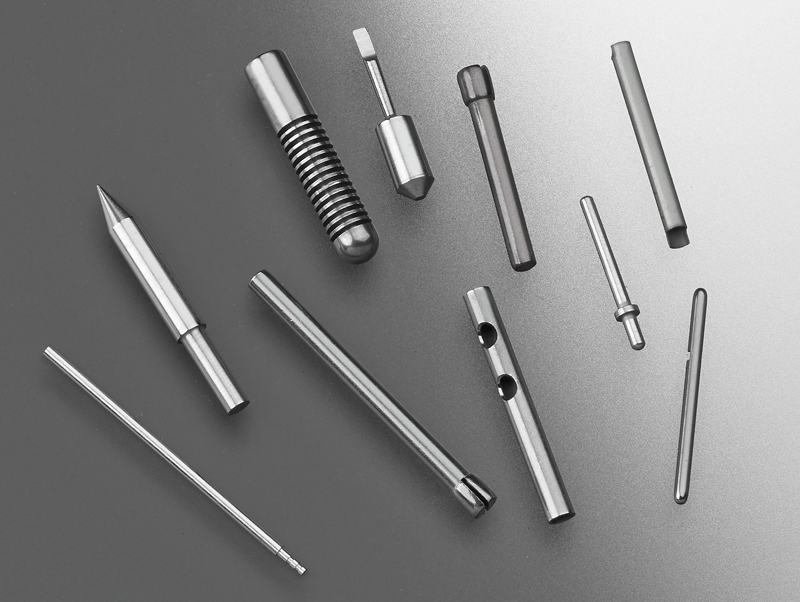

Tungsten has a high hardness and melting point, and it is difficult to process. However, the welding of flake or filament tungsten is relatively easy. Therefore, in vacuum systems tungsten is often used for electron emission filaments, cathodes of X-ray tubes, spring elements, high-temperature thermocouples, furnace evaporators, and welding electrodes.

Refractory Metals Properties - 2. Tantalum

Tantalum is a lightweight, high-strength refractory metal with a melting point of 2996 ° C. Chemically, tantalum has very good corrosion resistance. It does not react with aqua regia, chromic acid, nitric acid, sulfuric acid, and hydrochloric acid under hot and cold conditions, but it is soluble in hydrofluoric acid, fluoride solution, and oxalic acid.

Tantalum

At the same time, it can combine with hydrogen to form hydrides, destroying the properties of metals and causing brittleness. Besides, tantalum has a significant gettering performance for active gases and can absorb most of the residual gases in the vacuum system except for inert gases.

Refractory Metals Properties - 3. Molybdenum

Molybdenum is a refractory metal with high hardness and non-magnetic, and stable chemical properties. Its melting point is 2620 ° C. At high temperatures, molybdenum will be slowly oxidized at 520 ° C, and rapid oxidation will begin to occur above 600 ° C. At normal temperature or at a not-too-high temperature, molybdenum is stable in air or water.

Molybdenum

In terms of corrosion resistance, molybdenum is only corroded by a hot dilute hydrochloric acid solution and a 1: 1 mixture of hydrofluoric acid and nitric acid. In vacuum applications, molybdenum is heat-treated or added with niobium to increase tensile strength.

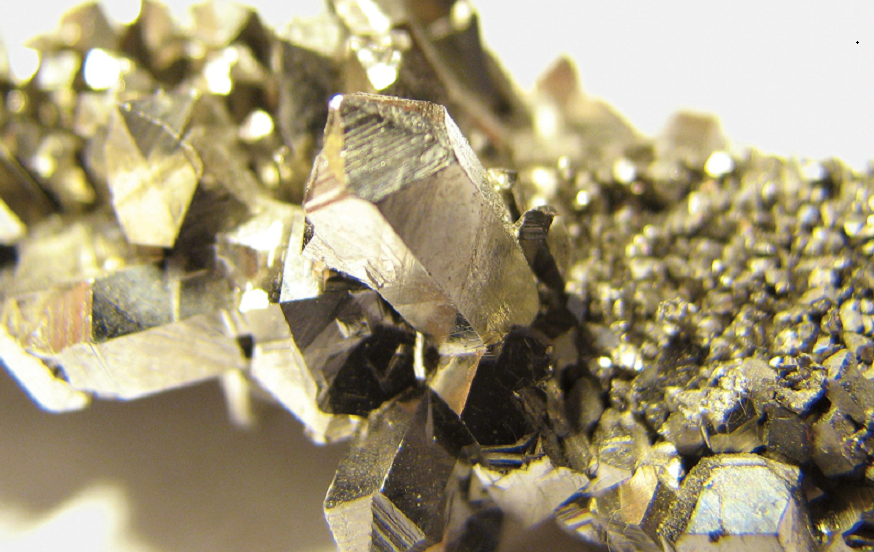

Refractory Metals Properties - 4. Niobium

Niobium has a melting point of 2468 ° C and is a refractory metal with high strength and small specific gravity. Niobium has various properties similar to tantalum, but it has a low melting point and a higher vapor pressure than tantalum, so it is rarely used as a hot electron emitter. Because of its strong affinity, niobium can be used as a getter, especially a high-temperature getter.

Niobium

In vacuum systems, it can also be used as a structural material. It is also commonly used in electric welding or electron beam welding. It is added to some stainless steels as an additive to prevent intergranular corrosion caused by carbon. In addition, this refractory metal can also be seen in the heating element and heat shield of the heating device in the vacuum equipment.

Conclusion

Thank you for reading our article and we hope you've enjoyed it. If you want to know more about refractory metals and refractory metals properties, you can visit Advanced Refractory Metals (ARM) for more information. We supply high-quality refractory metals to meet our customers’ R&D and production needs.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}