Nitinol Surface Oxide Layers: Varieties and Significance

Introduction

Nitinol is a nickel-titanium alloy notable for its unique shape memory and super elastic properties. It has garnered significant attention across various industries, from medical devices to aerospace engineering. Its surface oxide layer and other essential products greatly influence its application and performance.

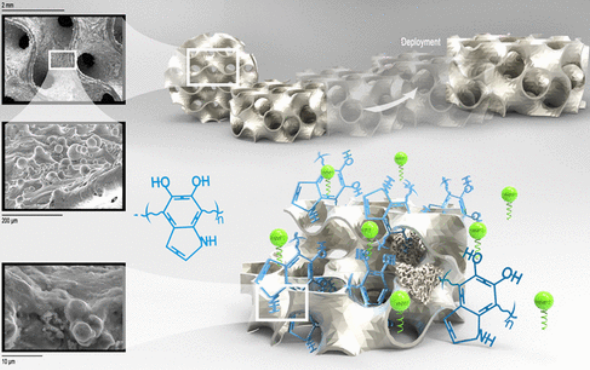

Surface Treatment of Nitinol [1]

This layer not only affects the alloy's biocompatibility and corrosion resistance. It also possesses many functions in different environments. Understanding the varieties of Nitinol surface oxide layers and their significance is crucial for leveraging this material's full potential in industry-specific applications.

The Nature of Nitinol Surface Oxide Layers

The surface oxide layer on Nitinol is a result of the alloy's exposure to oxygen.

- These layers are formed either during manufacturing processes or through deliberate surface treatments.

- They can vary in thickness, composition, and structure. It depends on the specific treatment applied and the intended use of the Nitinol component.

- The most commonly observed oxides on Nitinol include titanium dioxide (TiO2), nickel oxide (NiO), and mixed oxides that form complex structures at the surface.

Related reading: Nitinol – Amazing Shape Memory Alloy

Properties and Impact of the Oxide Layer

--Biocompatibility:

The oxide layer on nitinol is suitable for medical implants and devices. The bioinert titanium oxide contributes to the alloy's acceptance by the human body.

However, the presence of nickel in the oxide layer can raise concerns, as nickel ions can elicit allergic reactions in some individuals. Therefore, controlling the composition and thickness of the oxide layer is essential to minimize nickel release and improve biocompatibility.

--Corrosion Resistance:

The oxide layer enhances nitinol's resistance to corrosion, particularly in physiological environments. A stable and uniform oxide layer can act as a barrier to prevent aggressive substances from reaching the metal surface. Thus, it protects the underlying metal from degradation.

--Surface Properties:

The oxide layer affects the surface properties of nitinol, including its wettability, friction coefficient, and wear resistance. Modifying the oxide layer can tailor these properties for specific applications, such as improving the lubricity of medical devices to reduce tissue trauma during insertion or operation.

Varieties of Surface Oxide Layers

1. Passive Oxide Layer:

This naturally occurring layer forms when Nitinol is exposed to air or oxygen-containing environments. It is primarily composed of titanium dioxide (TiO2).

Such dioxide is notable for its excellent corrosion resistance and biocompatibility. The passive oxide layer is thin, typically a few nanometers thick. Yet, it provides a crucial barrier that protects the underlying metal from corrosion and wear.

2. Thick Oxide Layers:

Thicker oxide layers can be produced through various surface treatments. Such modifications include anodization, thermal oxidation, or plasma surface modification.

These treatments can enhance the thickness and alter the composition of the oxide layer, potentially improving the alloy's wear resistance, corrosion resistance, and surface hardness. Thick oxide layers might also affect Nitinol's fatigue life, an essential factor for applications requiring high cyclic loading.

3. Functional Oxide Layers:

Some surface treatments are designed to create oxide layers that impart specific functionalities to the Nitinol surface.

For example, oxide layers that improve endothelialization are particularly valuable for cardiovascular stents, while layers that enhance bone growth are sought after for orthopedic implants. These functional oxide layers can include dopants or incorporate other elements to provide the desired surface properties.

Significance of Nitinol Surface Oxide Layers across Industries

- Medical Devices:

In the medical field, the biocompatibility and corrosion resistance of Nitinol are paramount. The passive oxide layer, primarily composed of TiO2, is non-toxic and resistant to bodily fluids.

Therefore, it is ideal for implants and devices in direct contact with human tissue. Surface treatments that enhance this layer or add functional properties can further improve device performance and longevity. It reduces the risk of rejection or failure consequently.

- Aerospace and Automotive:

The durability and resilience of Nitinol components are critical in aerospace and automotive applications.

Enhanced oxide layers that increase wear and corrosion resistance can significantly extend the life of moving parts subjected to harsh environmental conditions or high stress. Functional oxide layers can also reduce friction. It contributes to more efficient fuel consumption and better performance.

- Consumer Electronics:

In consumer electronics, Nitinol is often used for its shape memory properties in actuators or connectors.

And, the surface oxide layer impacts the alloy's electrical conductivity and fatigue life. Tailored oxide layers can optimize these properties and ensure the reliability and durability of electronic devices.

Conclusion

The variety of Nitinol's surface oxide layers plays a critical role in the alloy's application across different industries. By understanding and manipulating these layers through specific surface treatments, engineers and designers can enhance Nitinol's inherent properties to meet the unique demands of medical devices, aerospace components, automotive parts, and consumer electronics.

As research and technology continue to advance, the potential for innovative applications of Nitinol expands. These devices further solidify their position as a material of choice for challenges requiring a combination of strength, flexibility, and precision.

Advanced Refractory Metals (ARM) stands at the forefront of Nitinol product supply. ARM offers both competitive prices and favorable lead times across our material range. We also excel in catering to custom requirements. Do not hesitate to contact us, if you are interested.

Reference:

[1] Z. Gorgin Karaji, M. Speirs, S. Dadbakhsh, J.-P. Kruth, H. Weinans, A. A. Zadpoor, and S. Amin Yavari. “Additively Manufactured and Surface Biofunctionalized Porous Nitinol.” ACS Applied Materials & Interfaces 2017 9 (2), 1293-1304. DOI: 10.1021/acsami.6b14026

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}