When of sufficient purity, zirconium is soft and ductile. Zirconium a transition metal has good corrosion resistance and low absorption capacity for thermal neutrons. These properties are desirable in materials used for certain parts of nuclear reactors. The great increase in the production of zirconium since 1945 has been the direct result of the construction of nuclear reactors.

Why Is Zirconium A Transition Metal?

Zirconium is obtained from zircon sand, which also contains a small percentage of hafnium oxide. In making reactor-grade zirconium, the hafnium must be removed so that the concentration of hafnium in the zirconium will be no more than 0. 01 percent. The production of hafnium is largely dependent on the production of reactor-grade zirconium. Zirconium and hafnium react much the same way in the usual refining processes, so separation is difficult.

Nevertheless, several processes have been developed for accomplishing the desired separation. Cast ingots of zirconium and the group of alloys known as the Zircaloys are produced by arc melting or by powder-metallurgical processes. The resulting ingots or compacts may be hot forged and rolled without protective atmospheres.

The forging temperature is about 1550℉ for the unalloyed metal and 1800℉ for the Zircaloys. Vacuum annealing is used in the finishing stages of fabrication to provide improved surface characteristics.

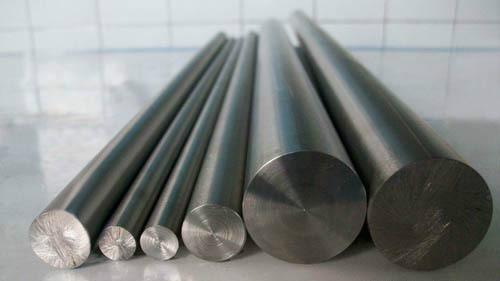

zirconium rod tubes

Zirconium may be hot extruded at about 1800℉, but some means must be used to protect the surface during heating. This may be done in a salt bath. The metal may also be cold-worked. Welding may be done in a suitable protective atmosphere.

Several alloys of zirconium have been developed to provide improved room-temperature and elevated-temperature strength and corrosion resistance without sacrificing other favorable properties. Zircaloy-2 contains about 1.5 percent tin and Zircaloy-3 contains about 0. Z5 percent tin. Both alloys also contain small amounts of iron, chromium, nickel, and traces of other elements.

In addition to nuclear-reactor components, zirconium metal is used for special corrosion-resistant equipment for the chemical industry, in photoflash bulbs, and for surgical applications.

Thank you for reading our article and we hope it can help you know better about zirconium a transition metal. If you want to know more about zirconium and other refractory metals, you can visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, ARM is a leading manufacturer & supplier of refractory metals across the world. We provide our customers with high-quality refractory metal products such as tungsten, molybdenum, tantalum, rhenium, titanium, and zirconium at a very competitive price.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.