In the world of high-performance electronics, the choice of materials plays a critical role in determining the efficiency, durability, and overall performance of devices. Among the various materials used, copper beryllium stands out for its exceptional properties and versatile applications.

This article discusses the significance of copper beryllium in electronics, detailing its composition, properties, key applications, advantages over other alloys, processing methods, and future trends.

Copper beryllium, also known as beryllium copper or BeCu, is an alloy primarily composed of copper and beryllium, with additional elements such as cobalt, nickel, and iron in smaller quantities. The typical composition ranges from 0.5% to 3% beryllium, with copper making up the majority. This unique combination results in a material that boasts an impressive array of properties.

Related reading: 5 Common Uses Of Beryllium Copper Alloys

Copper beryllium offers several advantages over other alloys commonly used in electronics. One of its most significant benefits is its superior fatigue strength, which allows it to withstand repeated mechanical stress without degrading. This property is particularly important in applications where components are subject to frequent mechanical movements, such as connectors and spring contacts.

Additionally, copper beryllium’s excellent conductivity ensures efficient electrical performance, making it a preferred choice for applications that require high conductivity and strength. Its corrosion resistance further enhances its suitability for use in environments where components may be exposed to moisture or corrosive substances.

In comparison to other materials like brass or phosphor bronze, copper beryllium provides a unique combination of high strength, conductivity, and durability, making it an unmatched choice for high-performance electronic applications.

Copper beryllium is widely used in several critical applications within the electronics industry, thanks to its outstanding properties. Here are some of its primary applications:

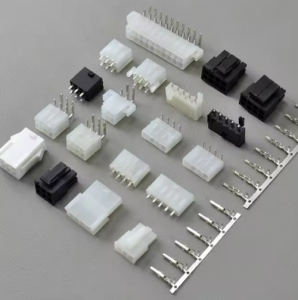

Copper beryllium is extensively used in connectors and switches due to its excellent conductivity and mechanical strength. These components are essential for ensuring reliable electrical connections in electronic devices. The durability and resistance to wear and tear provided by copper beryllium make it a preferred choice for connectors and switches that must withstand repeated use and harsh environments.

The exceptional spring properties of copper beryllium make it ideal for use in spring contacts. These contacts maintain consistent electrical connections, which is crucial for the reliable operation of various electronic devices. The material’s elasticity and ability to return to its original shape after deformation ensure long-lasting performance and reliability.

Relays and relay contacts benefit greatly from the properties of copper beryllium. The material’s high strength and resistance to electrical arcing enhance the longevity and reliability of relays, which are critical components in many electronic systems. The use of copper beryllium in relay contacts ensures stable and efficient performance, even under demanding conditions.

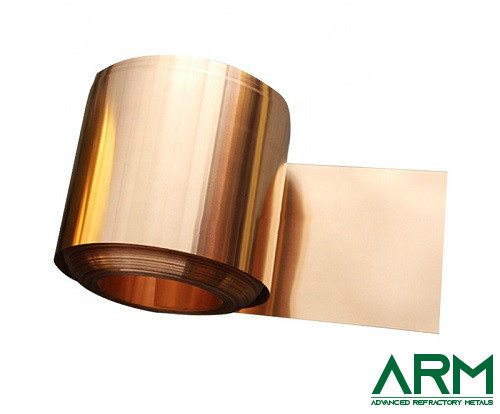

The processing and manufacturing of copper beryllium involve several steps to achieve its desired properties. The alloy is typically produced through melting and casting processes, followed by various forms of mechanical working, such as rolling, forging, and extrusion.

As the electronics industry continues to evolve, the demand for materials that can offer higher performance and reliability is increasing. Future trends in the use of Copper Beryllium alloys in electronics include:

Copper beryllium is a critical material in high-performance electronics, offering a unique combination of strength, conductivity, and durability. Its applications in connectors, switches, spring contacts, and relays highlight its versatility and reliability.

As the electronics industry evolves, the demand for copper beryllium is expected to grow, driven by its unmatched properties and the continuous advancements in material science and processing technologies.

Advanced Refractory Metals (ARM) is a premier manufacturer and supplier of Beryllium Copper Alloys. We offer beryllium copper sheets, strips, and wires, with customized shapes and component ratios available upon request. For more information, please visit our homepage.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.