The porous titanium plate is a material with excellent filtering performance, usually manufactured by the metal powder rolling method. Powder rolling is a process in which metal powder is directly rolled into metal. First, the metal powder is rolled into a strip on a powder rolling mill, and then sintered, cold-rolled (or hot-rolled), and annealed to make a dense or porous finished strip.

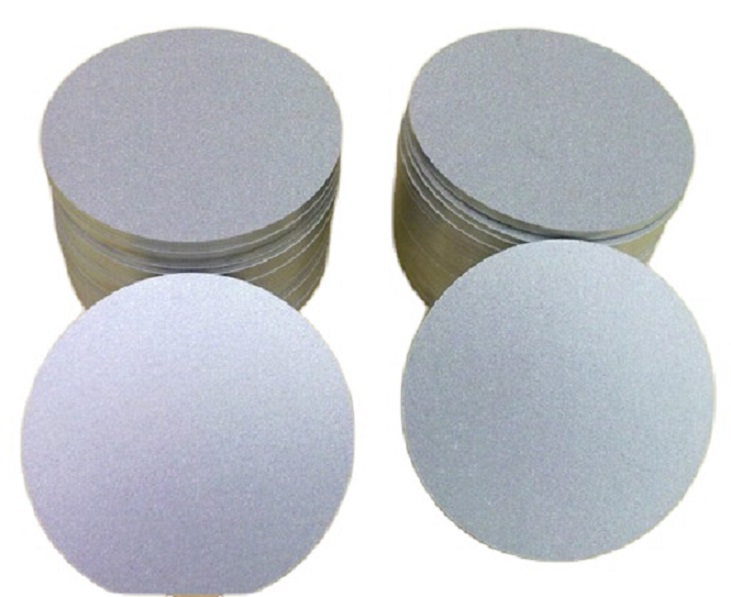

Porous Titanium Plate

The porous titanium plate made of titanium metal powder has excellent corrosion resistance of titanium and can resist the erosion of various concentrations of nitric acid and most acid-base solutions. At the same time, it also has the advantages of non-toxic, high-temperature resistance, high strength, high porosity, uniform air permeability, and easy cleaning.

The treatment of drinking water and industrial wastewater by the ozone method is a technology that has developed rapidly at home and abroad in recent years. The working principle of this method is: that the ozone is evenly poured into the sewage through the porous sheet, and a chemical reaction occurs with the sewage, so as to achieve the purpose of disinfection, decolorization, and purification.

Therefore, it is required that the porous sheet used is resistant to corrosion by industrial sewage and ozone, and has a high porosity and gas ratio, a uniformly distributed pore size, and a certain strength. In the past, some sewage treatment plants used polyvinyl chloride porous plates, ceramic porous plates, glass porous plates, and other materials for sewage treatment. However, these materials cannot meet the requirements due to poor corrosion resistance and low strength. However, the invention of the porous titanium plate solves this problem.

At present, porous titanium plates have been used as ozone diffusion plates in the treatment of printing film wastewater, organic dye wastewater treatment, oil refining wastewater treatment, hospital sewage treatment, and rocket engine test sewage treatment.

In the treatment of printing film wastewater, the original use of a polyvinyl chloride porous plate, the service life is only 350 hours, after replacing it with a porous titanium plate, the service life is increased to 3 years.

In the ozone treatment of oil refinery wastewater, polyvinyl chloride perforated plates were originally used, but the ozone absorption rate was only 65%, which wasted a lot of ozone and increased the cost of wastewater treatment. The use of porous titanium plates increased the ozone absorption rate to 85%, which greatly improves the processing effect.

In addition, porous titanium plates can also be used as various filters, reverse osmosis devices, and medical materials. In short, the porous titanium plate, a new type of material, has now shown its strong vitality and will be widely used in all aspects of life in the future.

Thank you for reading our article and we hope it can let you have a better understanding of the porous titanium plate. If you want to know more about titanium and titanium plates, we would like to advise you to visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, USA, Advanced Refractory Metals (ARM) is a leading manufacturer & supplier of refractory metals across the world. It provides customers with high-quality refractory metals and alloys such as titanium, titanium plate, tungsten, molybdenum, tantalum, rhenium, and zirconium at a very competitive price.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.