As the basic material in the field of high-temperature technology, refractory materials are widely used in steel, non-ferrous metals, glass, cement, ceramics, petrochemicals, machinery, boilers, light industry, electric power, military, and other fields. With the development of technology, the preparation technology of refractories is developing in the field of fine ceramics, and some special refractories are developed. At present, advanced preparation technology is also widely used in refractories. Then how is the new technology applied in refractories?

How Is the New Technology Applied in Refractories?

The following are the specific applications of nanotechnology. In situ synthesis, Self-propagating High-temperature Synthesis(SHS), and Functional Gradient Materials (FGM) technology in refractory materials.

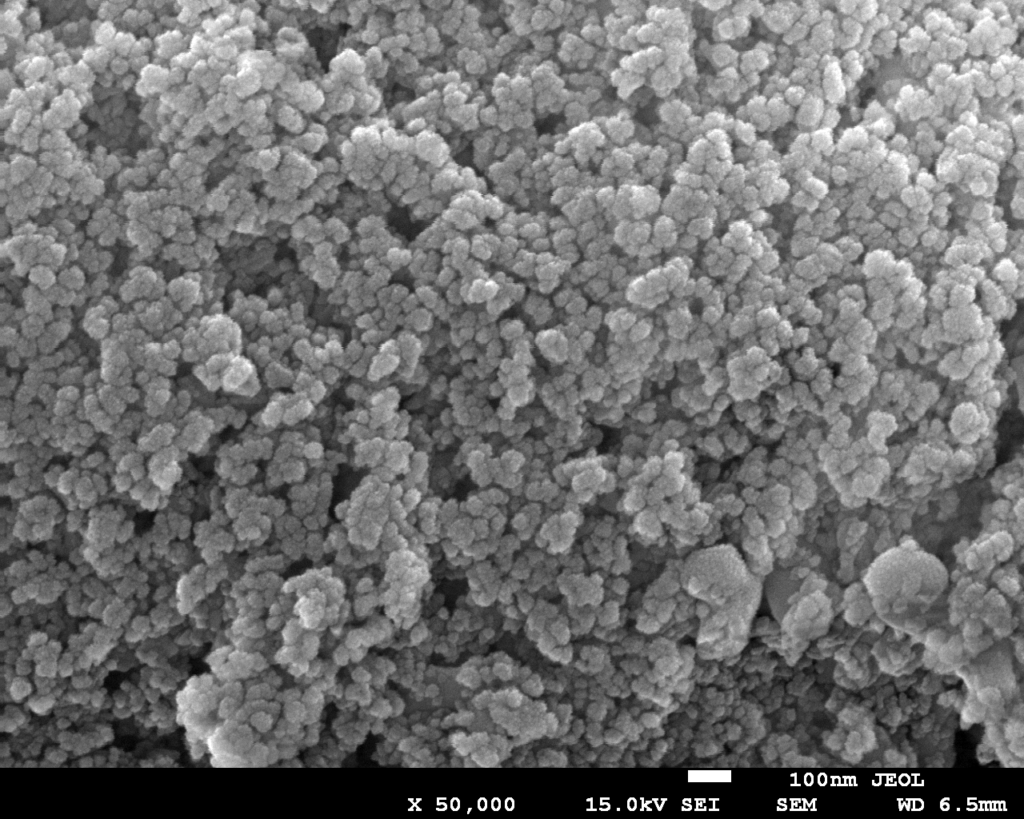

The application of nanotechnology in refractories is mainly to introduce nanopowder into refractories. High-purity corundum powder introduced into α-Al2O3 nanopowder and α-Al2O3 powder can promote solid-phase sintering and improve the sintering performance of the product.

In MgO-C composite refractory, the use of nano-carbon powder to replace flake graphite or to form nano-fiber in the original position of the matrix can significantly improve the performance of MgO-C refractory.

α-Al2O3 nanopowder

In situ, synthesis technology refers to the generation of the second phase by the reaction to improve the properties of refractories, the advantage of which is that it can overcome the inherent defects of the second phase and reduce the price of the product. For example, SiC whiskers grown by in-situ synthesis technology can significantly enhance the strength and toughness of the Al2O3-C refractory.

With the development of self-propagating synthetic, it has been applied in the field of refractories. At present, the refractory materials prepared by the self-propagating synthesis techniques are used in the lining of aluminum smelting furnaces with natural raw materials such as magnesite, dolomite, and chromite.

In addition, the SHS also has a certain application, and the process is to fill the appropriate reaction raw materials between the two refractories through SHS technology to make the intermediate raw materials react and then weld the two refractories.

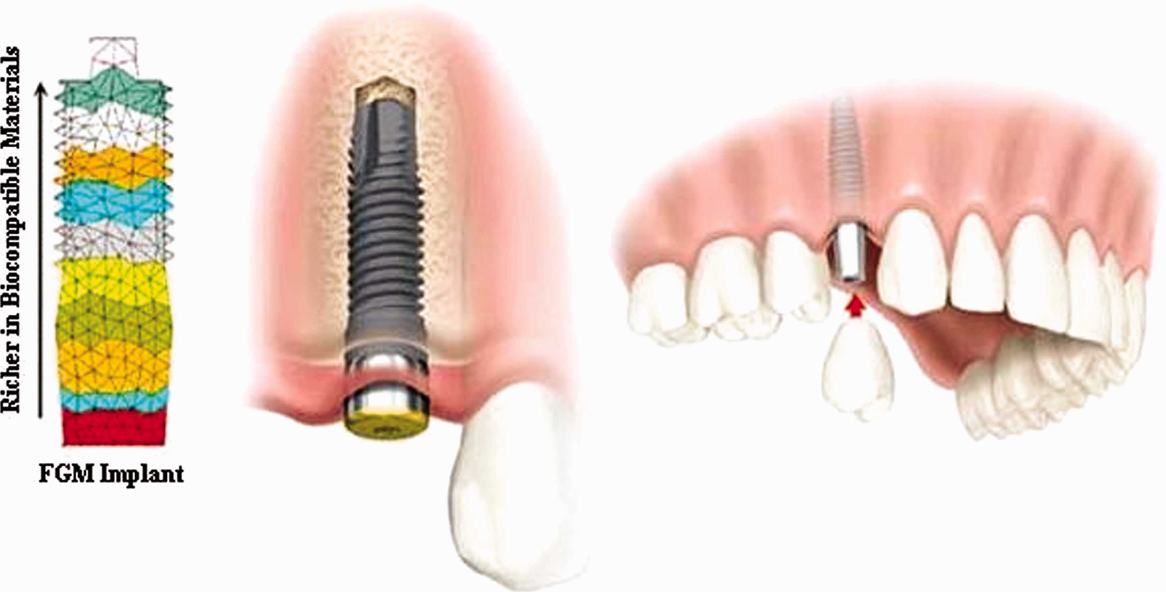

FGM is a new type of composite material developed to meet the need for repeated normal operation under the environment of super high temperatures and large temperature drops. The remarkable feature of the material is that the components, structures, and physical properties of the material change continuously.

THE FGM dental implant

The FMG technology applied in the refractories is mainly based on the different parts of the refractory performance and structure requirements.

For example, a composite nozzle and multilayer lining materials are designed according to the thermal expansion characteristics between different materials and thermal stress problems.

However, the application of FGM in refractories should not only solve theoretical problems but also consider economic benefits.

Thank you for reading our article and we hope it can let you have a better understanding of how is the new technology applied in refractories. If you want to know more about refractory materials, you can visit Advanced Refractory Metals (ARM) for more information.

Headquartered in Lake Forest, California, Advanced Refractory Metals is a leading manufacturer and supplier of refractory metals, providing customers with high-quality refractory metals to meet customers’ R&D and production needs.

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.