Beryllium X-ray foil and window assemblies are critical components in various scientific and industrial applications, particularly in X-ray and neutron imaging. This article will discuss the applications, benefits, and specific cases of using beryllium X-ray foil and window assemblies.

[1]

[1]

Beryllium, known for its unique combination of properties, is the material of choice for these applications due to its low atomic number, high transparency to X-rays, and excellent mechanical strength.

Related reading: 6 Common Uses of Beryllium

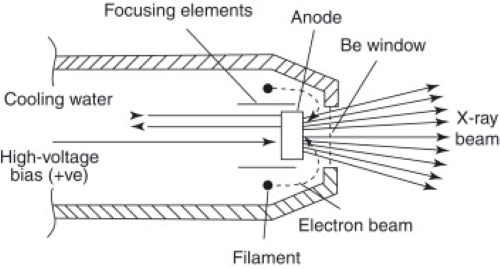

– Medical Imaging: Beryllium windows are used in X-ray tubes and detectors in medical imaging systems, including mammography and computed tomography (CT) scanners. Their transparency to X-rays allows for clear, high-contrast images, which are essential for accurate diagnosis.

– X-Ray Spectroscopy: In X-ray spectroscopy, beryllium windows enable the detection of low-energy X-rays by minimizing absorption, thereby improving the sensitivity and accuracy of the analysis.

– Synchrotron Radiation Facilities: Beryllium foils are used as windows in synchrotron beamlines to transmit X-rays with minimal loss of intensity, facilitating high-precision experiments and research in materials science, chemistry, and biology.

– Neutron Radiography: Beryllium windows are also used in neutron radiography systems, where they allow the passage of neutrons while blocking other radiation types, enabling detailed imaging of internal structures in components like engine parts and nuclear fuel assemblies.

– Vacuum Chambers: Beryllium windows are commonly used in vacuum chambers where they provide a barrier between the vacuum environment and the X-ray source or detector while allowing X-rays to pass through efficiently.

– High-Pressure Cells: In high-pressure experimental setups, beryllium windows are used to maintain the integrity of the cell while permitting X-ray or neutron analysis of the materials under study.

– Spacecraft Instrumentation: Beryllium X-ray windows are utilized in spaceborne instruments for detecting cosmic X-rays. Their light weight and high strength make them suitable for use in the demanding conditions of space.

Beryllium X-ray foil and window assemblies offer several advantages due to their unique properties. The material’s low atomic number allows for high X-ray transmission, which minimizes signal loss and significantly enhances image quality. Additionally, beryllium’s durability ensures reliable performance even under harsh environmental conditions, such as high radiation levels, extreme temperatures, and mechanical stress. The precision manufacturing capabilities of beryllium enable the production of very thin foils and complex window assemblies, providing tailored solutions for specific applications.

However, there are important considerations when using beryllium. Its toxicity poses serious health risks if inhaled as dust or fumes, necessitating strict safety protocols during handling and machining, including the use of protective equipment and adequate ventilation systems. Moreover, beryllium’s relative expense limits its application to scenarios where its unique properties are indispensable, making it a specialized material choice in certain industries.

There are lots of scholarly articles related to beryllium X-ray foils and window assemblies, each exploring different facets of their properties, applications, and improvements.

Related reading: Beryllium: Understanding Its Toxicity and Safety Measures

The research on beryllium X-ray foils and window assemblies has yielded numerous insights that are critical for enhancing the performance of X-ray technologies. Here are some specific cases and data.

– Case Study: In a study by Mishin et al. (2018), superfine beryllium foils with a thickness of 15 μm were used in X-ray fluorescence spectrometers. The researchers reported that these foils improved the spectrometer’s ability to detect low concentrations of elements by reducing background noise and enhancing signal clarity. The study showed a detection limit improvement of up to 20% when compared to conventional foils, demonstrating the significant impact of foil quality on analytical performance.

– Case Study: In another experiment, Mishin and Shishov (2018) examined the deformation and fracture behavior of beryllium foils with thicknesses ranging from 5 to 30 μm under static loading conditions. They found that foils with a thickness of 12 μm exhibited the highest resistance to fracture, withstanding pressures up to 300 MPa without failure. This data is particularly relevant for applications in X-ray detectors where the foils must maintain structural integrity under high-stress conditions.

– Case Study: A durability assessment of beryllium foils used in X-ray detectors, conducted by Mishin et al. (2018), focused on foils exposed to prolonged high-temperature conditions. The study found that foils maintained 95% of their original mechanical strength after 1,000 hours at 200°C, indicating their suitability for use in environments such as aerospace or nuclear applications where long-term stability is required.

– Case Study: In research on high-purity beryllium foils prepared by vapor deposition (Taylor, 1982), foils were shown to have impurity levels below 0.01%. These high-purity foils demonstrated exceptional X-ray transmission, with transmission rates exceeding 95% for X-rays in the 1-10 keV range. This high level of purity and transmission makes them ideal for use in sensitive scientific instruments like synchrotrons, where accurate measurements are critical.

– Case Study: The ITER project, which aims to develop nuclear fusion as a viable energy source, uses beryllium windows in its radial X-ray cameras to monitor plasma behavior. Chen et al. (2013) reported that beryllium foils with a thickness of 80 μm were chosen for these windows due to their excellent X-ray transmission and ability to withstand thermal stresses exceeding 500°C. The study provided data showing that these foils maintained their performance after repeated exposure to extreme temperatures and radiation.

– Case Study: Wells et al. (1993) evaluated beryllium foils for use in X-ray lithography beamlines, where foils are exposed to high-intensity X-ray beams. The study found that foils with a thickness of 10 μm provided optimal balance between mechanical strength and X-ray transmission. Specifically, these foils demonstrated a tensile strength of 450 MPa and an X-ray transmission rate of 98% at 8 keV, making them suitable for precise lithographic processes in semiconductor manufacturing.

Beryllium X-ray foil and window assemblies are indispensable in applications in fields ranging from medical imaging and scientific research to aerospace and nuclear fusion for their high X-ray transparency, durability, and stability are required. While the use of beryllium requires careful handling and safety considerations, its benefits make it a vital material in cutting-edge technology and research. Beryllium continues to be a key enabler of advancements in technology and research, driving innovation in critical sectors. For more Beryllium products, please check Advanced Refractory Metals (ARM).

Reference:

[1] Paul Worsfold, Alan Townshend and Colin Poole (2005). Encyclopedia of Analytical Science (2nd ed.). Elsevier Academic Press. https://www.sciencedirect.com/referencework/9780123693976/encyclopedia-of-analytical-science

Copyright © 1994-2024 Advanced Refractory Metals owned by Oceania International LLC, All Rights Reserved.